Design and function

Interfaces for automation

099-000121-EW501

29.06.2015

5.15 Interfaces for automation

Damage to the machine due to improper connection!

Unsuitable control leads or incorrect connection of input and output signals can cause

damage to the machine.

• Only use shielded control leads!

• If the machine is to be operated with control voltages connection via suitable isolation

amplifiers is required!

• To control the main or secondary current via control voltages, the relevant inputs must be

enabled (see specification for activation of control voltage).

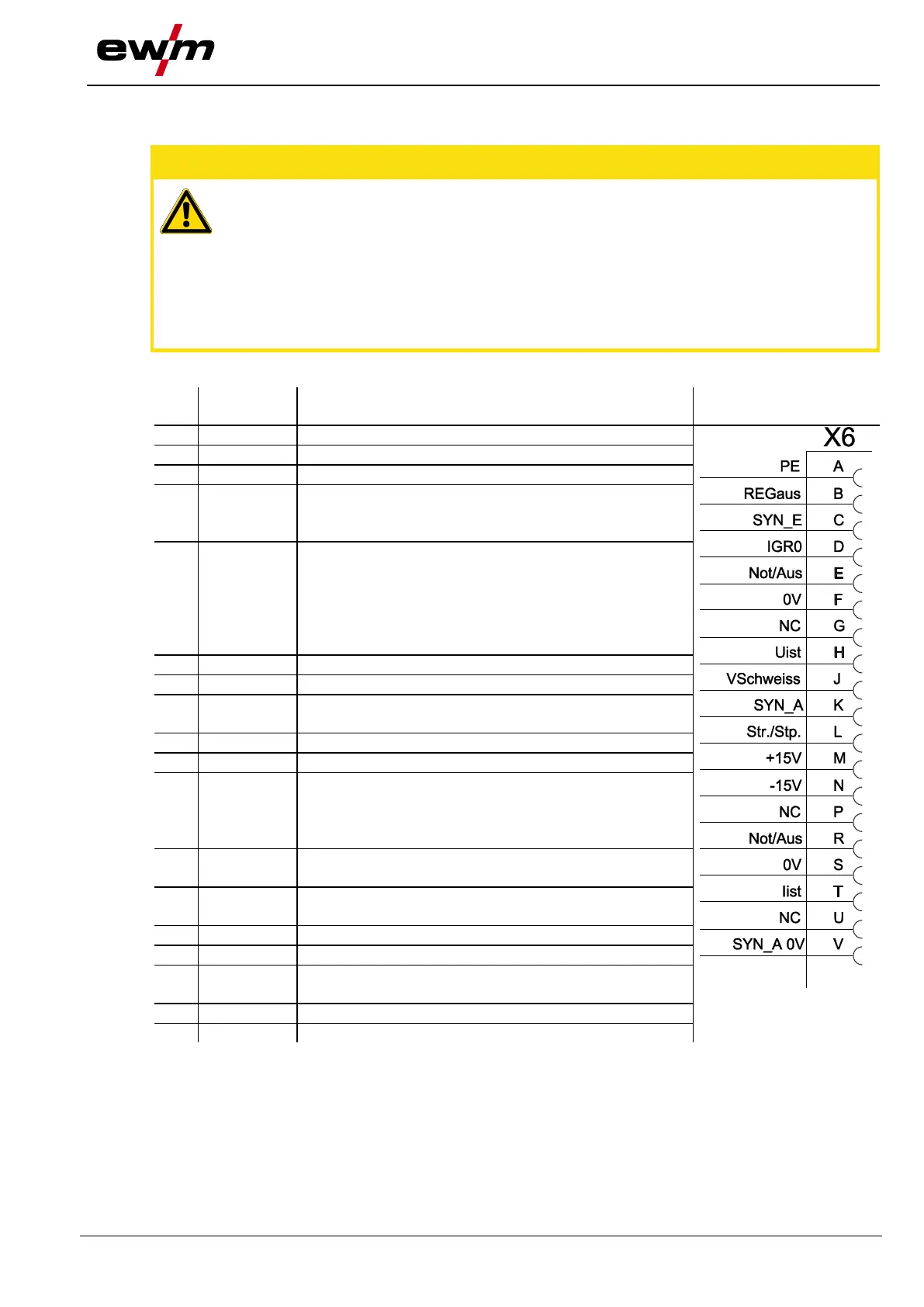

5.15.1 TIG interface for mechanised welding

PE Connection for cable screen

REGaus For servicing purposes only

SYN_E Synchronisation for master/slave operation

IGRO Current flows signal I>0 (maximum load

20mA / 15V)

0V = welding current flowing

Not/Aus Emergency stop for higher level shut-down

of the power source.

To use this function, jumper 1 must be

unplugged on PCB T320/1 in the welding

machine. Contact open welding current

off

Uist Actual welding voltage, measured on pin F,

0-10V (0V = 0V, 10V = 100V)

Vschweiss Reserved for special purposes

SYN_A Synchronisation for master/slave operation

Str/Stp Start / stop welding current, same as torch

trigger.

Only available in non-latched operating

mode. +15V = start, 0V stop

+15V Voltage supply

+15V, max. 75mA

-15V Voltage supply

-15V, max. 25mA

Iist Actual welding current, measured on pin F;

0-10V (0V = 0A, 10V = 1000A)

SYN_A 0V Synchronisation for master/slave operation

Loading...

Loading...