Design and function

TIG welding

099-000121-EW501

29.06.2015

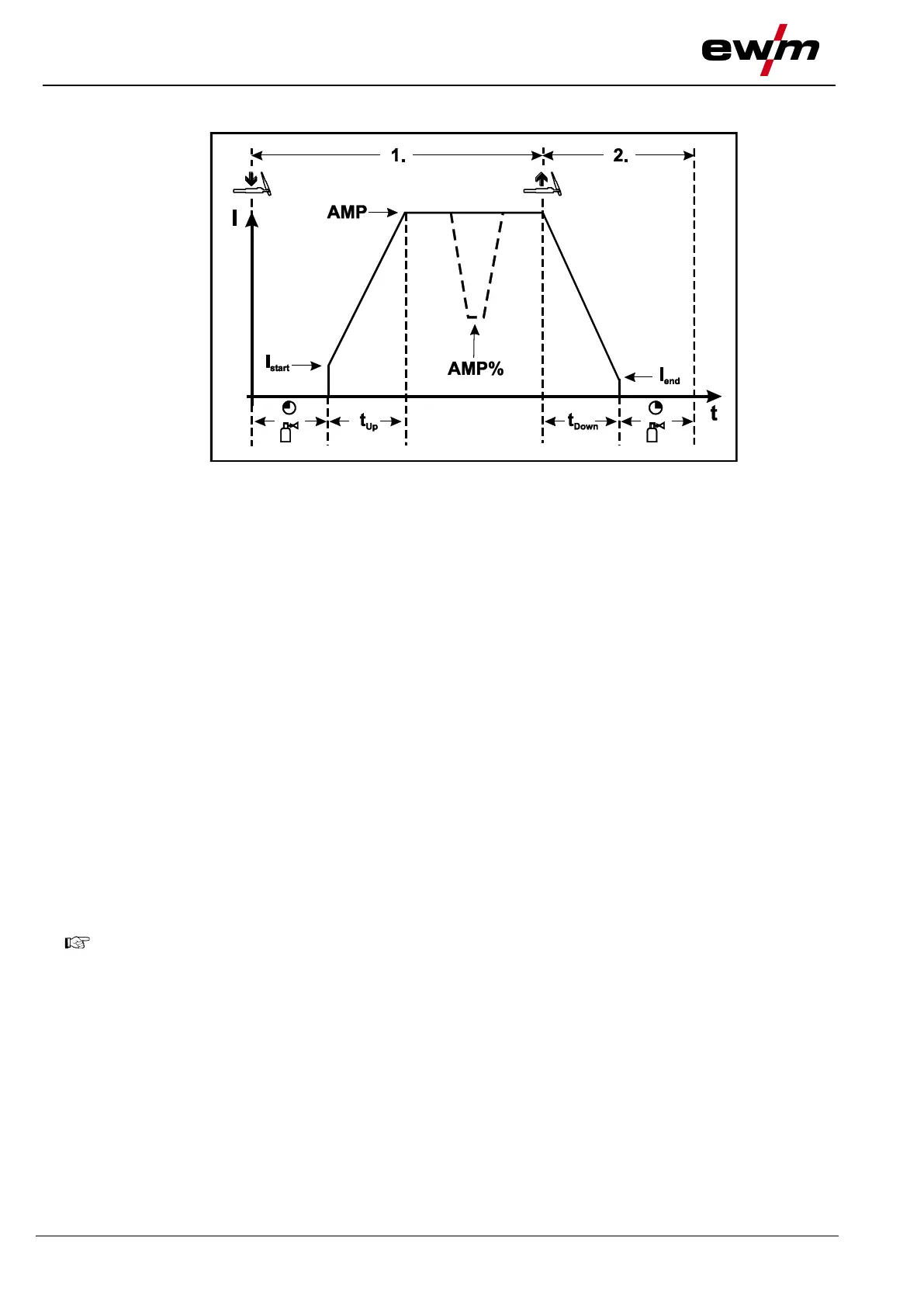

5.9.11.2 Non-latched mode

Figure 5-18

1st cycle:

• Press and hold torch trigger 1.

• The gas pre-flow time elapses.

• HF ignition pulses jump from the electrode to the workpiece, the arc ignites.

• The welding current flows and immediately assumes the value set for the ignition current I

start

.

• HF is switched off.

• The welding current increases with the adjusted up-slope time to the main current AMP.

If torch trigger 2 is pressed in addition to torch trigger 1 during the main current phase, the

welding current drops at the slope time set (tS1) to the secondary current AMP%.

After torch trigger 2 is released, the welding current rises at the slope time set (tS2) back to the

main current AMP.

2nd cycle:

• Release torch trigger 1.

• The main current falls in the set down-slope time to the

end-crater current I

end

(minimum current).

If the 1st torch trigger is pressed during the down-slope time,

the welding current returns to the main current AMP set.

• The main current reaches the end-crater current I

end

, the arc extinguishes.

• The set gas post-flow time elapses.

When the foot-operated remote control RTF is connected, the machine switches automatically to

non-latched operation.

The up- and down-slopes are switched off.

Loading...

Loading...