Design and function

TIG welding

099-000121-EW501

29.06.2015

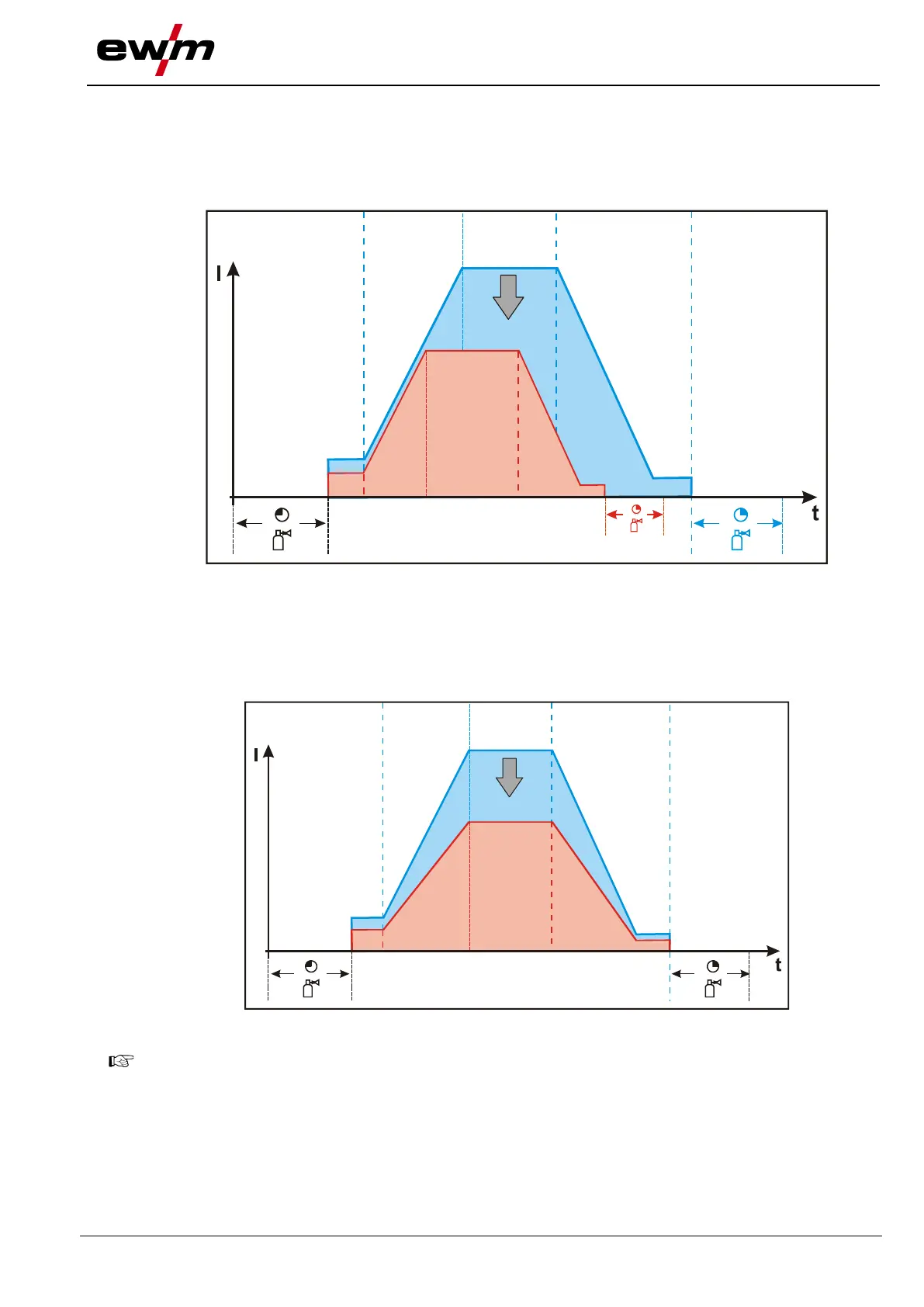

5.9.3 Synergic parameter setting in the functional sequence

When setting the welding current, all the necessary welding parameters are adjusted automatically during

the functional sequence - See 4.3.1 Function sequence chapter with the exception of the gas pre-flow

time. These welding parameters can also be set in the conventional way if required (regardless of the

welding current) - See 5.9.4 Conventional parameter setting in the functional sequence chapter.

Figure 5-11

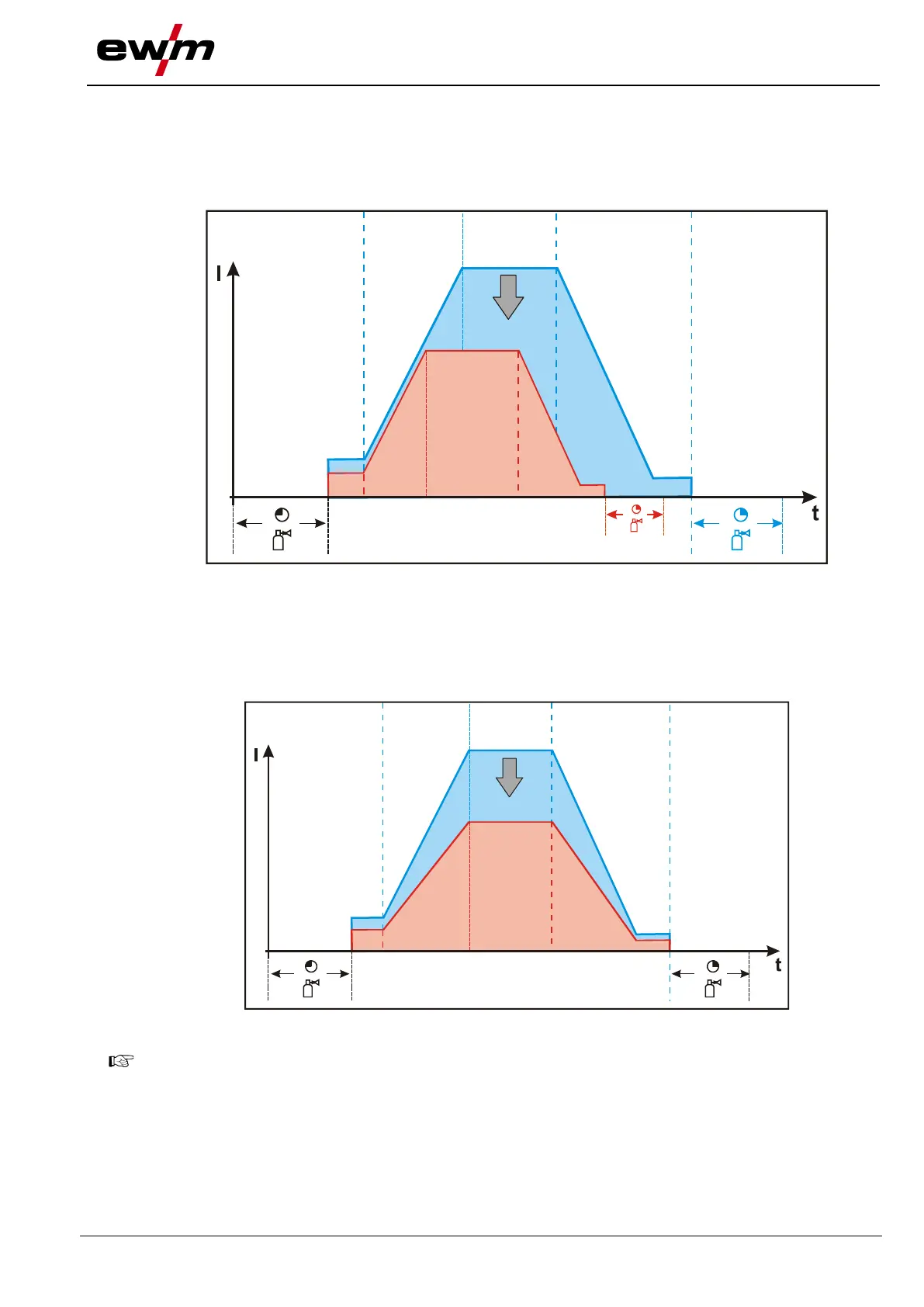

5.9.4 Conventional parameter setting in the functional sequence

All welding parameters in the functional sequence can also be adjusted, regardless of the welding current

set. This means that if the welding current is changed, the values for the down slope time or gas post-flow

time remain unchanged, for example. The welding task still needs to be selected as before using the

three basic parameters of tungsten electrode diameter, material type and seam type.

Figure 5-12

The parameters for the ignition, secondary and end currents can be set and displayed as

percentage values or absolute values- See 5.18 Machine configuration menu chapter.

Loading...

Loading...