Design and function

MMA welding

099-000121-EW501

29.06.2015

5.10 MMA welding

Risk of being crushed or burnt.

When replacing spent or new stick electrodes

• Switch off machine at the main switch

• Wear appropriate safety gloves

• Use insulated tongs to remove spent stick electrodes or to move welded workpieces and

• Always put the electrode holder down on an insulated surface.

Shielding gas connection!

During MMA welding open circuit voltage is applied at the shielding gas connection

(G¼" connecting nipple).

• Place yellow insulating cap on the G¼" connection nipple (protects against electrical

voltage and dirt).

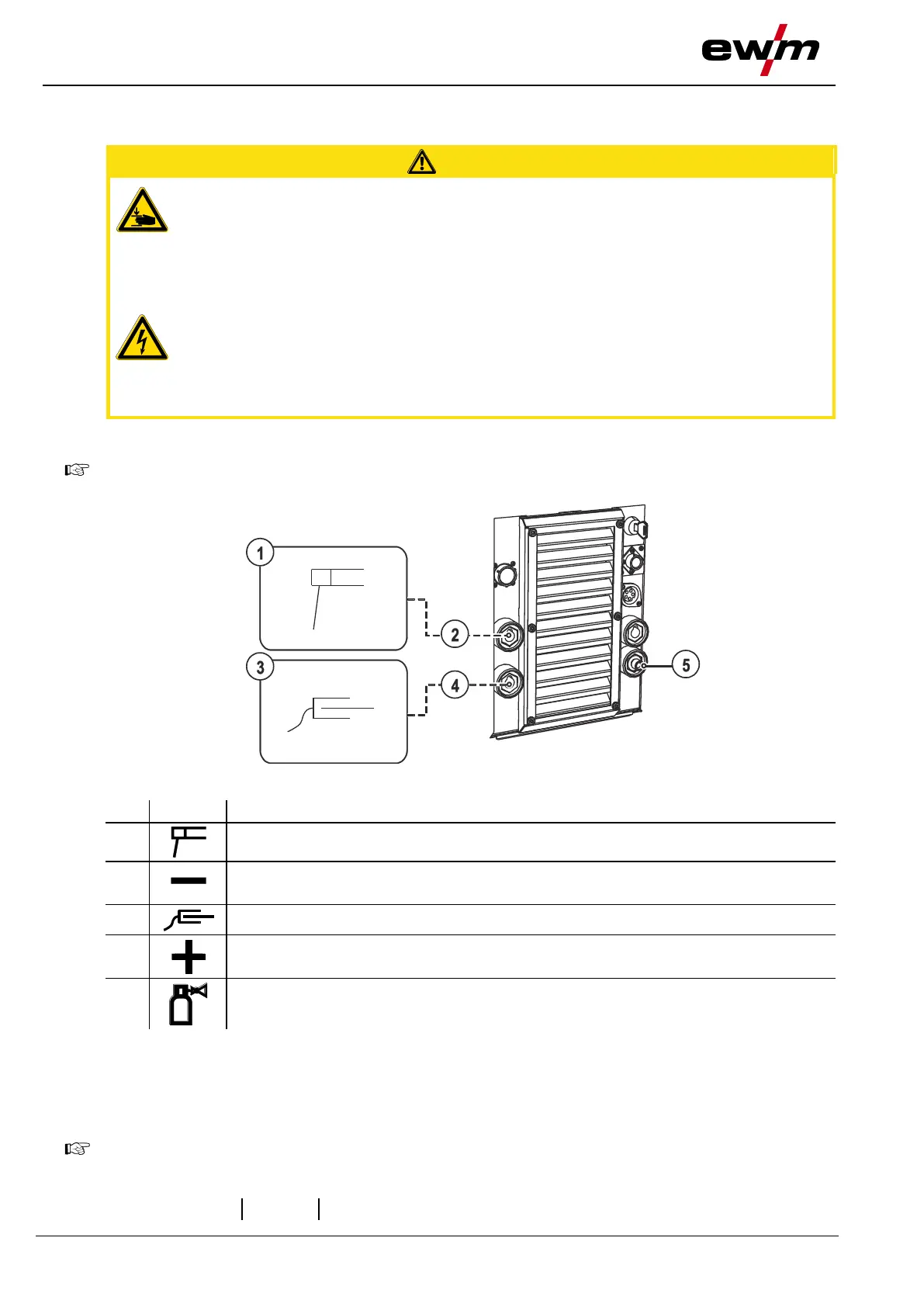

5.10.1 Connecting the electrode holder and workpiece lead

Polarity depends on the instructions from the electrode manufacturer given on the electrode

packaging.

Figure 5-36

Connection socket, “-” welding current

Workpiece lead or electrode holder connection

Connection socket for "+" welding current

Electrode holder or workpiece lead connection

G¼” connecting nipple, “-” welding current

Shielding gas connection (with yellow insulating cap) for TIG welding torch

• Fit yellow protective cap onto G¼" connecting nipple.

• Insert cable plug of the electrode holder into either the "+" or "-" welding current connection socket and

lock by turning to the right.

• Insert cable plug of the workpiece lead into either the "+" or "-" welding current connection socket and

lock by turning to the right.

The welding current polarity can be reversed on the machine control

"- See 5.10.3 Welding current polarity reversal (polarity reversal) chapter".

5.10.2 Select welding task

Loading...

Loading...