Design and function

TIG welding

099-000121-EW501

29.06.2015

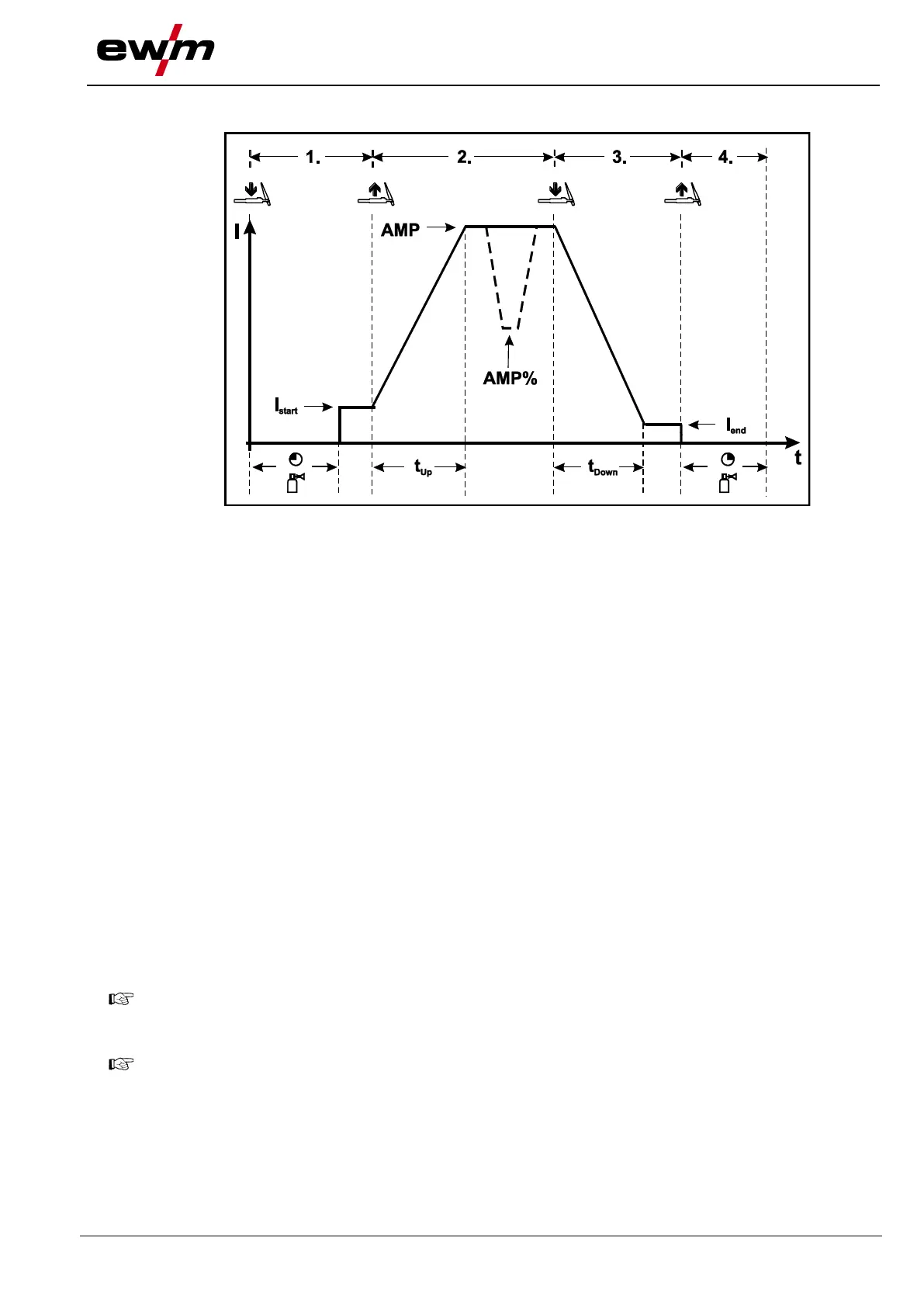

5.9.11.3 Latched mode

Figure 5-19

Step 1

• Press torch trigger 1, the gas pre-flow time elapses.

• HF ignition pulses jump from the electrode to the workpiece, the arc ignites.

• Welding current flows and immediately assumes the ignition current value set (search arc at minimum

setting). HF is switched off.

Step 2

• Release torch trigger 1.

• The welding current increases with the set up-slope time to the main current AMP.

Switching from main current AMP to secondary current AMP%:

• Press torch trigger 2 or

• Tap torch trigger 1

The slope times can be set.

Step 3

• Press torch trigger 1.

• The main current drops with the set down-slope time to the end-crater current I

end

(minimum current).

Step 4

• Release torch trigger 1, the arc extinguishes.

• The set gas post-flow time begins.

Immediate termination of the welding procedure without down-slope and end-crater current:

• Briefly press the 1st torch trigger (3rd and 4th step).

The current drops to zero and the gas post-flow time begins.

When the foot-operated remote control RTF is connected, the machine switches automatically to

non-latched operation.

The up- and down-slopes are switched off.

To use the alternative welding start (tapping start) a double-digit torch mode (11-x) has to be set

at the welding machine control. The number of torch modes available depends on the machine

type. For single-digit torch modes (1-x) this function is disabled.

Loading...

Loading...