Design and function

Machine configuration menu

099-000121-EW501

29.06.2015

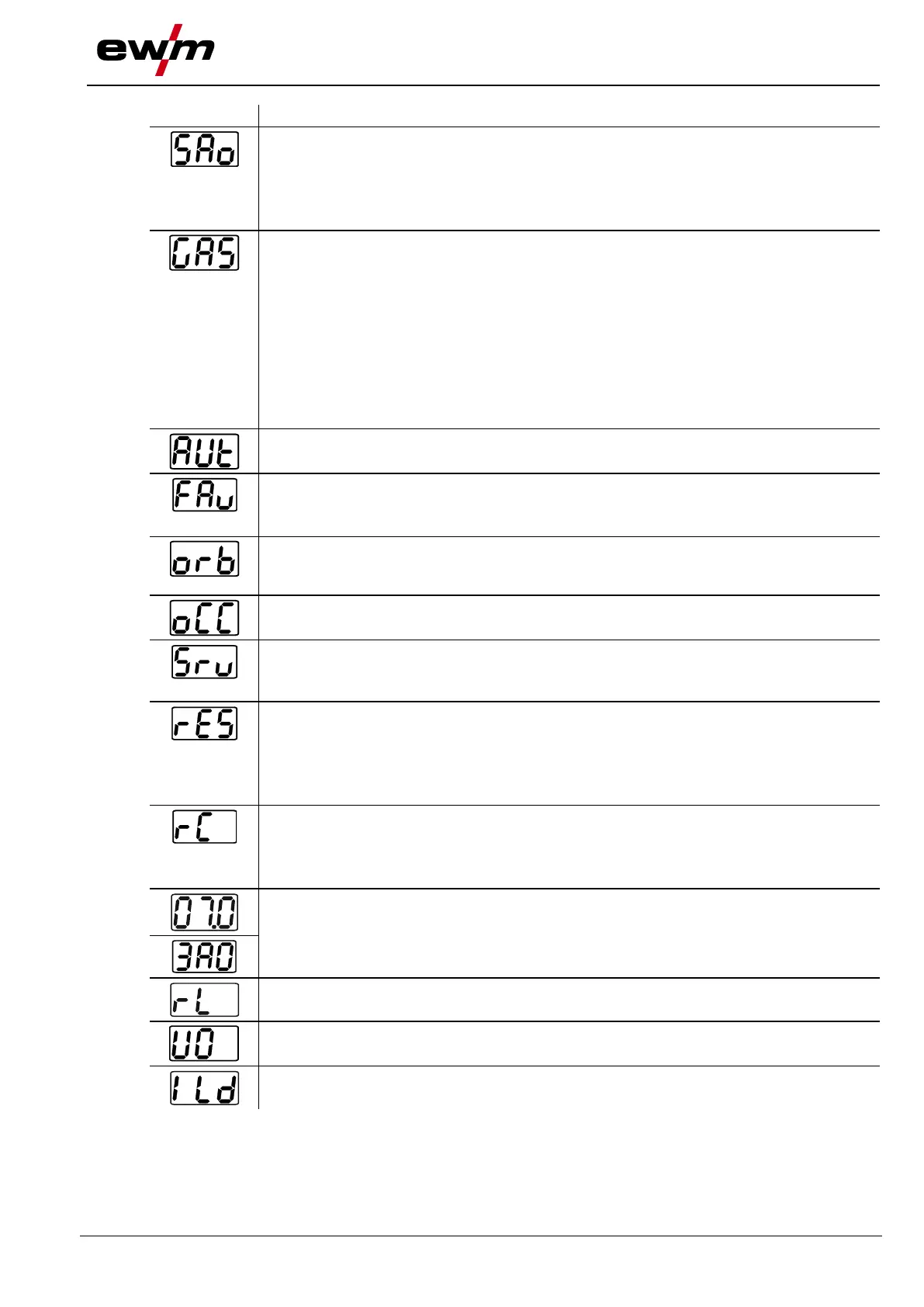

Error output to automated welding interface, contact SYN_A

off AC synchronisation or hot wire (factory setting)

FSn Error signal, negative logic

FSP Error signal, positive logic

AvC AVC (Arc voltage control) connection

Gas monitoring

Depending on where the gas sensor is situated, the use of a pilot static tube and the

welding process monitoring phase.

off Function switched off (ex works)

1 Monitoring during the welding process. Gas sensor between gas valve and

welding torch. With pilot static tube.

2 Monitoring prior to the welding process. Gas sensor between gas valve and

welding torch. Without pilot static tube.

3 Permanent monitoring Gas sensor between gas cylinder and gas valve. With

pilot static tube.

Fast take-over of control voltage (automation)

• on = function on

• off = function off (factory setting)

Orbital welding

• off = off (ex works)

• on = on

Orbital welding

Correction value for orbital current

Service menu

Modifications to the service menu may only be carried out by authorised maintenance

staff!

Reset (reset to factory settings)

• off = aus (factory setting)

• CFG = Reset the values in the machine configuration menu

• CPL = Complete reset of all values and settings

The reset is performed when leaving the menu (EXIT).

Automated/Manual (rC on/off) operating mode

Select machine/function control

on: with external control voltages/signals

off: with machine control

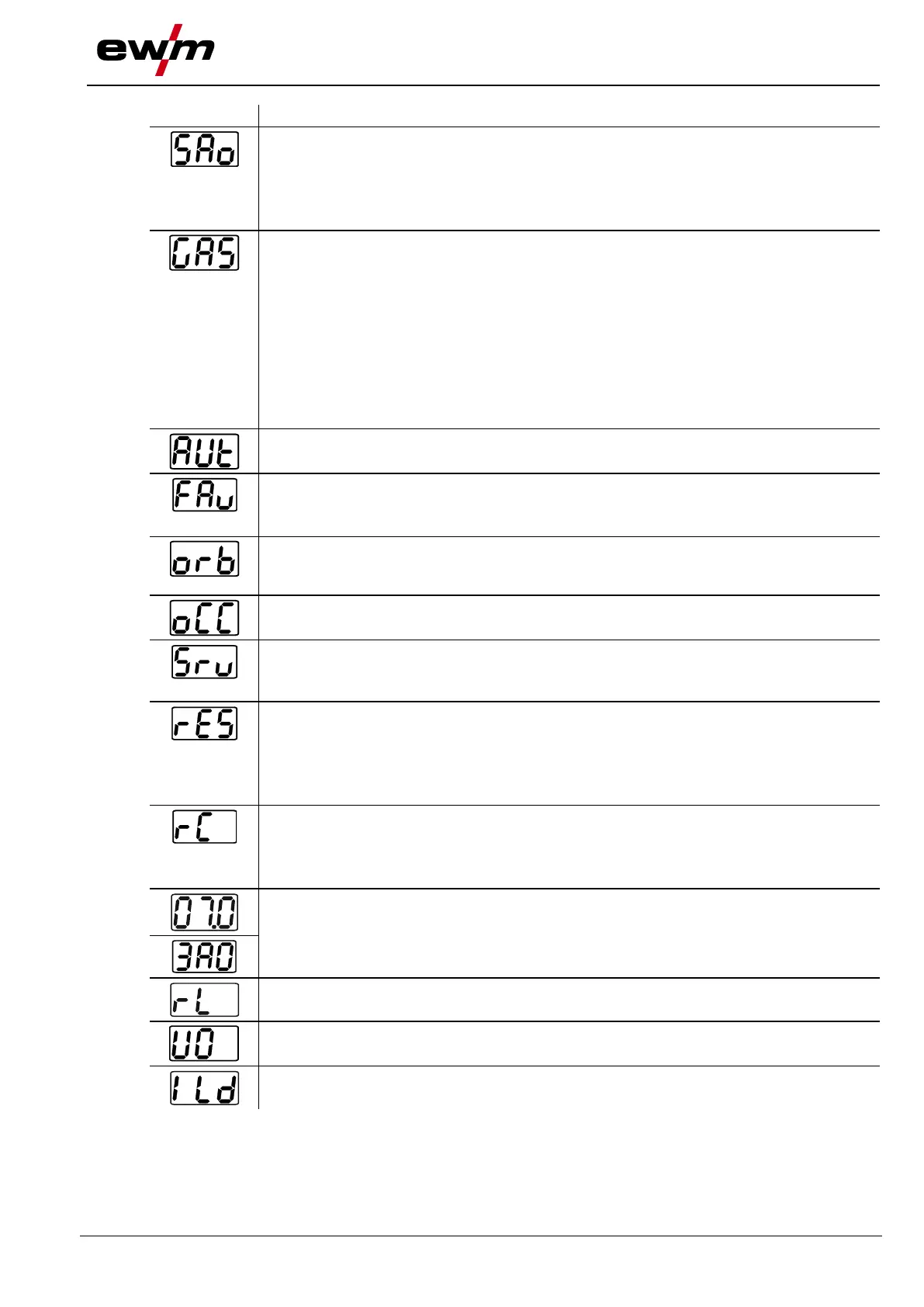

Software version query (example)

07= System bus ID

03A0= Version number

System bus ID and version number are separated by a dot.

Only qualified service personnel may change the parameters!

Only qualified service personnel may change the parameters!

Ignition pulse limit

Setting 0 ms–15 ms (increments of 1 ms)

Loading...

Loading...