Operation

1. Stop the mac hine and mo v e the dri v e lev ers to

the neutral position.

2. Diseng ag e the PTO .

3. Eng ag e the park brak e .

4. Stop the engine , remo v e the k ey and w ait for all

mo ving par ts to stop .

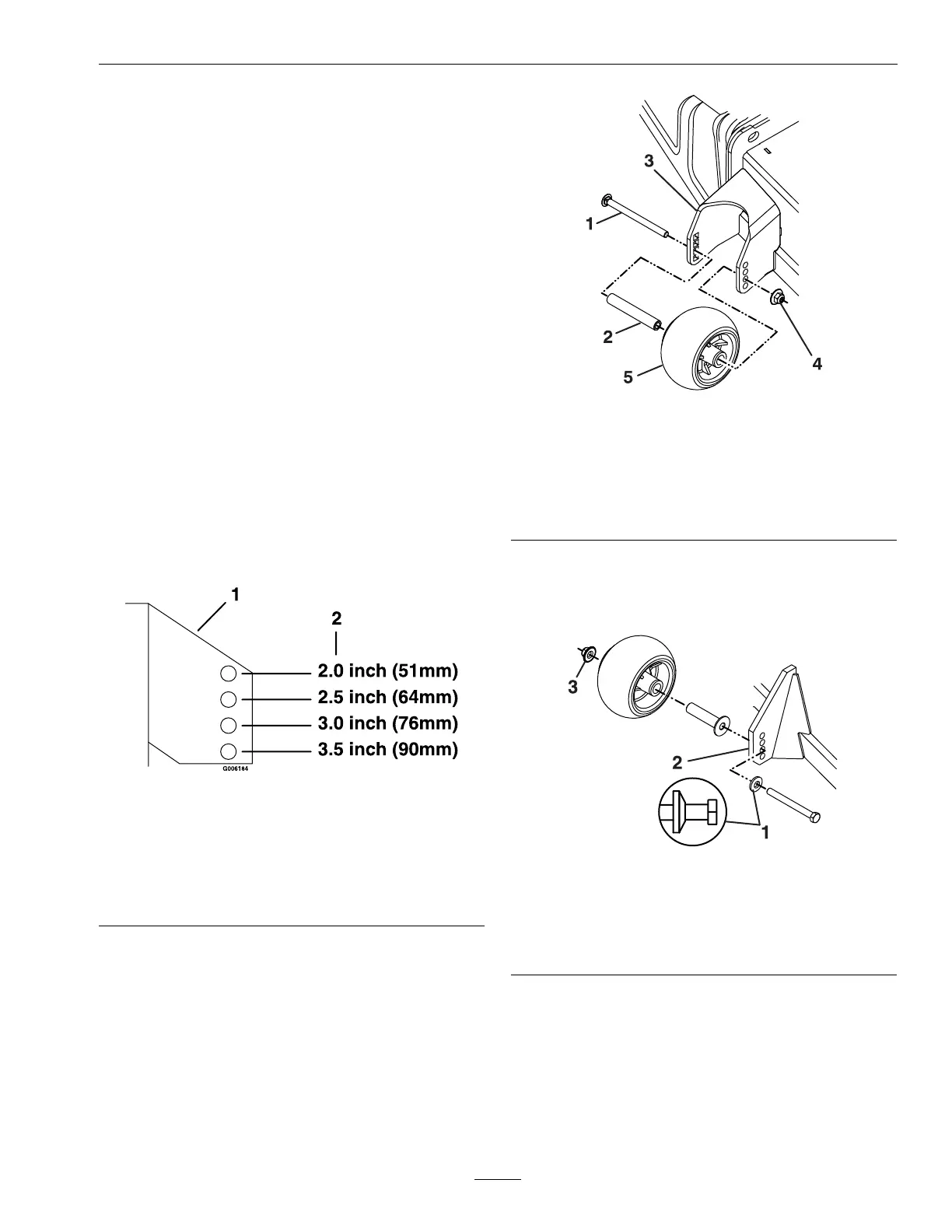

5. After adjusting the height of cut, adjust the

anti-scalp rollers b y remo ving the nyloc n ut,

spacer , and bolt.

6. Adjust anti-scalp rollers for nor mal operating

conditions . Place rollers in one of the positions

sho wn in Figure 12 . R ollers will maintain 3/4

inc hes (19 mm) clearance to the g round to

minimize g ouging and roller w ear or damag e .

Note: F or Maximum Deck F lotation , place

rollers one hole position lo w er . R ollers should

maintain 1/4 inc h (6.35 mm) clearance to g round.

Do Not adjust rollers to suppor t the dec k.

Note: R oller ma y need to be remo v ed when

mo wing at 1 inc h (25 mm).

g006184

Figure 12

For cutting heights above 3.5 inches (38 mm) use the

bottom hole. The rollers will still be ef fective against

scalping.

1. Anti-scalp roller

mounting bracket

2. Cutting height

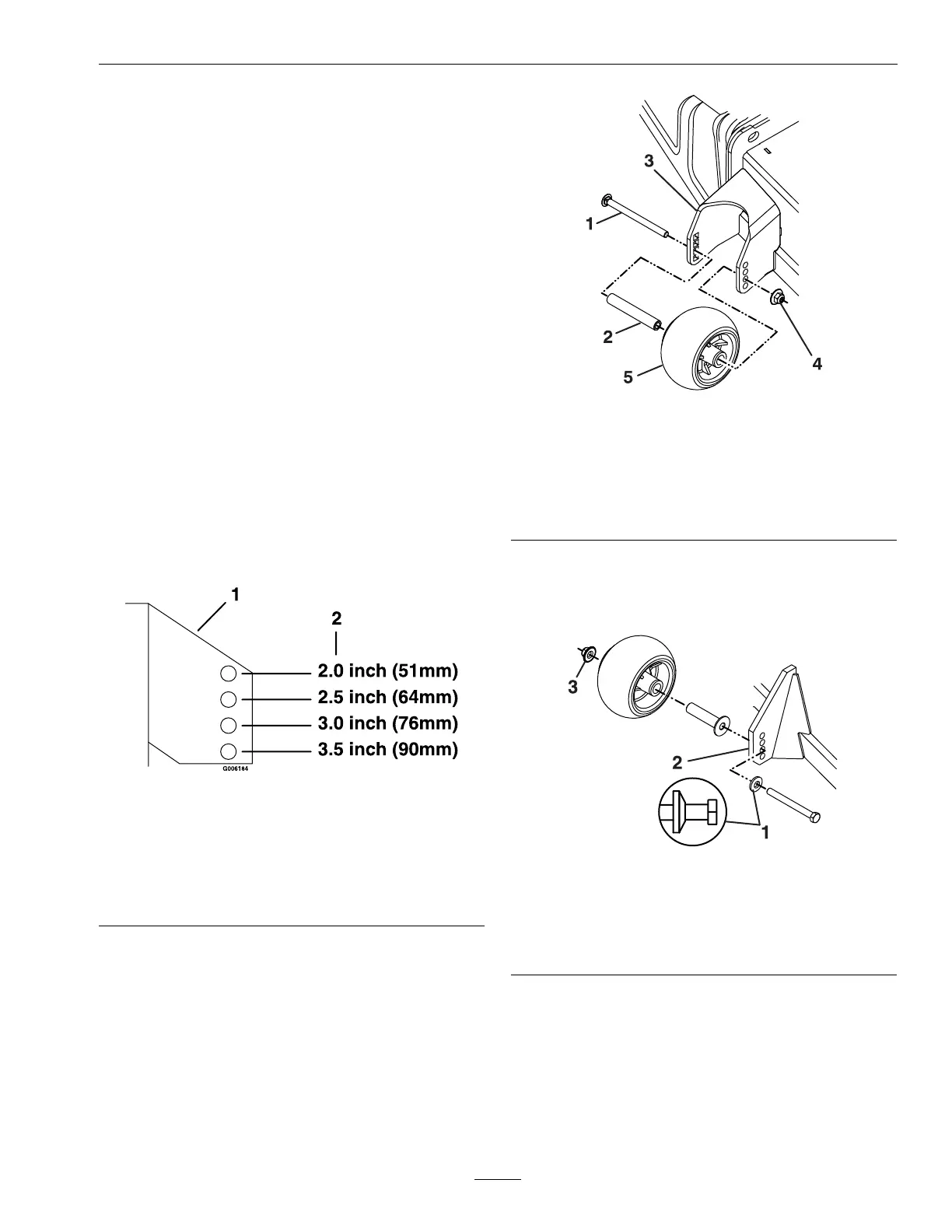

7. F or S-Series: Be sure roller bolts are installed

with the spring disc w asher betw een head of the

bolt and mounting brac k et.

8. R einstall the mounting hardw are:

• F or X-Series:

the 3/8-16 nyloc n ut to 27-33 ft-lb (37-45

N-m) ( Figure 13 ).

g433945

Figure 13

1. 3/8-16 x 5 inch bolt 4. 3/8 nyloc- to 27-33 ft-lb

(37-45 N-m)

2. Spacer

5. Anti-scalp roller

3. Front right anti-scalp

bracket shown

• F or S-Series:

the 3/8-16 nyloc n ut to 50–55 ft-lb (68-75

N-m) ( Figure 14 ).

g345136

Figure 14

1. 3/8-16 x 3 3/4 Grade 8

bolt

3. Front right anti-scalp

bracket shown

2. Spring disc washer

(cone towards bolt )

4. 3/8 nyloc- to 50–55 ft-lb

(68-75 N-m)

29

Loading...

Loading...