2 Product overview

16 Festo – P.BE-CPX-CMAX-SYS-EN – en 2017-09b – English

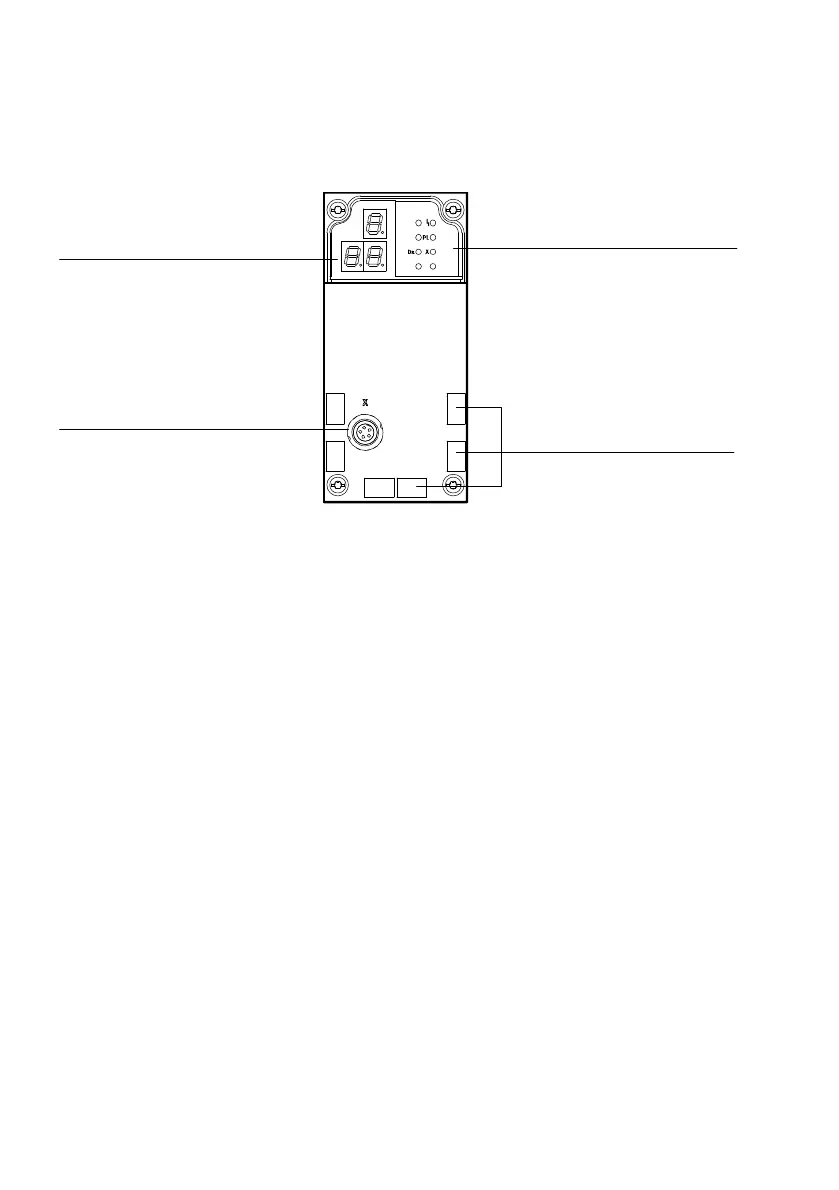

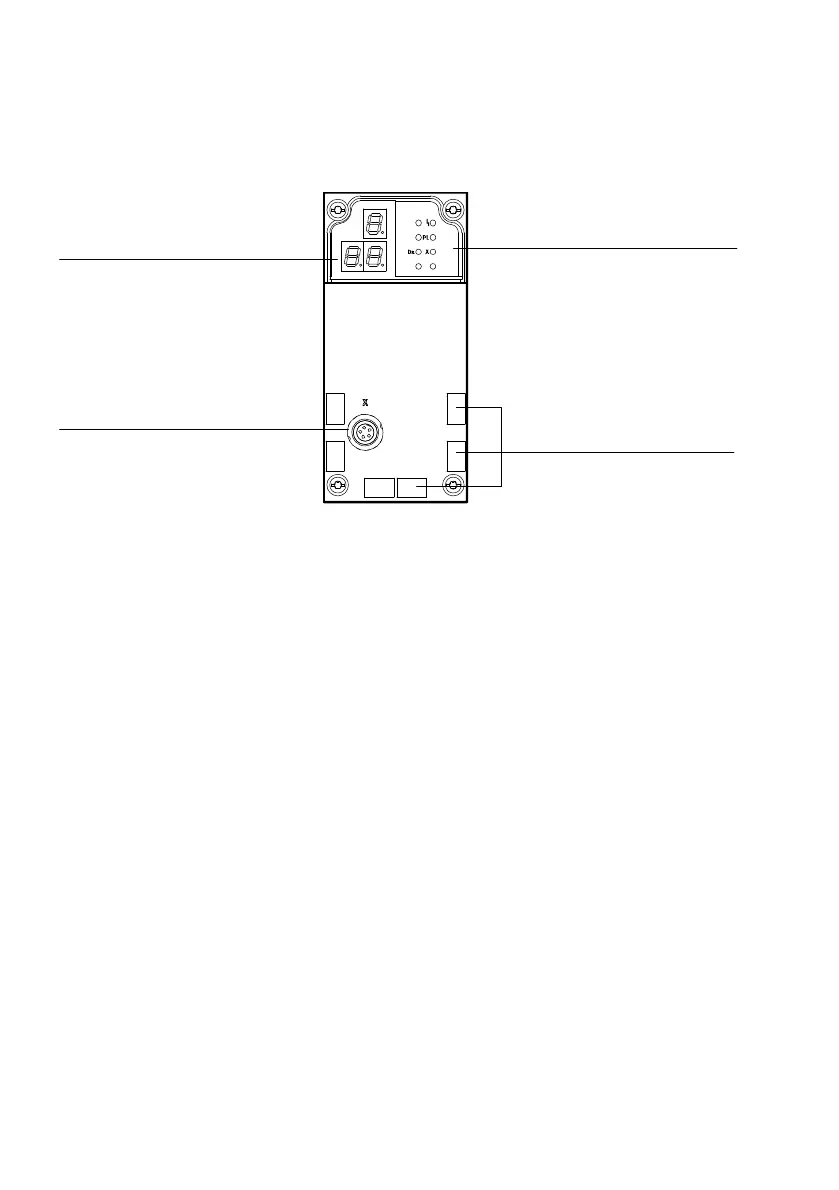

2.2 Connection and display components

1

2

3

4

1 Seven-segments display

2 Status LEDs

3 Inscription labels (6)

4 Axis connection (connection for VPWP)

Fig. 2.2 Control section and connections Axis controller CPX-CMAX

2.3 Function and application

2.3.1 Tasks of the CMAX

The CMAX takes over the following functions:

– storage of all project parameters (e.g. hardware configuration, records, controller settings)

– determination of system characteristic values of the connected components (identification)

– specification of the setpoint values (position or force) calculated from the specified target value and

the parameterised movement profile

– tracking of the actual value (position or force control) in case of deviation through corresponding

control of the proportional directional control valve

2.3.2 Mode of operation

The CMAX, valve, drive and displacement encoder are connected with each other to form a closed-loop.

In combination with a proportional directional control valve VPWP and a drive with a displacement en

coder, the CMAX axis controller forms a positioning system for pneumatic axes (è Section 1.2). The

positioning system permits the following:

– travel at selectable speed with previously configured acceleration in any positions (position control)

– application of a defined force with configured force edge [N/s] (force control) with simultaneous

speed and position monitoring

Loading...

Loading...