6 Diagnostics and error handling

Festo – P.BE-CPX-CMAX-SYS-EN – en 2017-09b – English 71

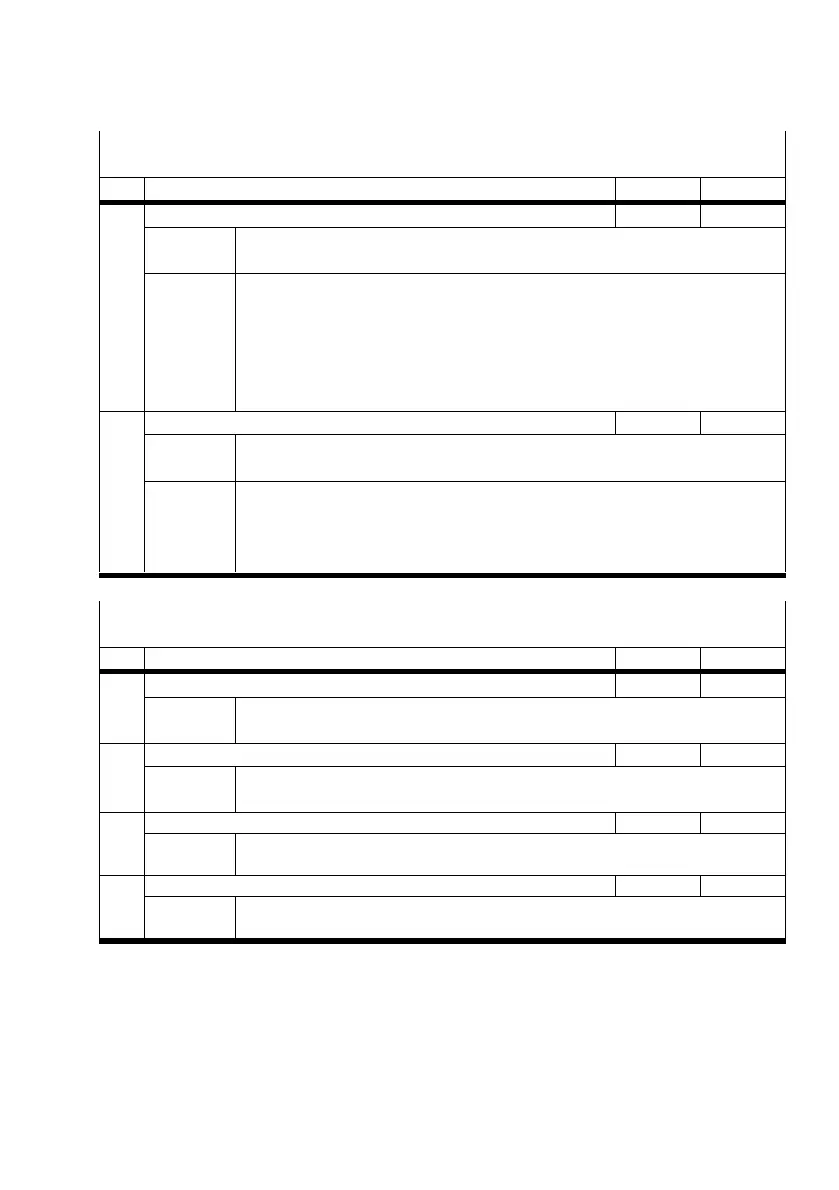

Group 0 − Configuration errors

CPX error group 100 (CPX-MMI: [Configuration error] )

No. Reset typeError levelMessage

08 Cylinder, valve or sensor interface was replaced W F

Note The movement test is reset to avoid tubing connection errors. The CMAX has C03

status. The movement test should then be run once more.

Cause The serial number of a component on the axis string has changed:

– drive (displacement encoder)

– valve

Measure 1. Accept the serial number of the component.

2. Run movement test (recommendation).

3. Perform identification (recommendation).

09 Project contains incorrect parameters F2 N

Cause Drive configuration is not supported by the firmware used.

Measure Update firmware.

Cause Invalid values concerning axis parameters or hardware configuration (e.g. soft

ware end positions).

Measure Determine, check and correct the affected parameters with additional inform

ation (diagnostics: Active messages or diagnostic memory)

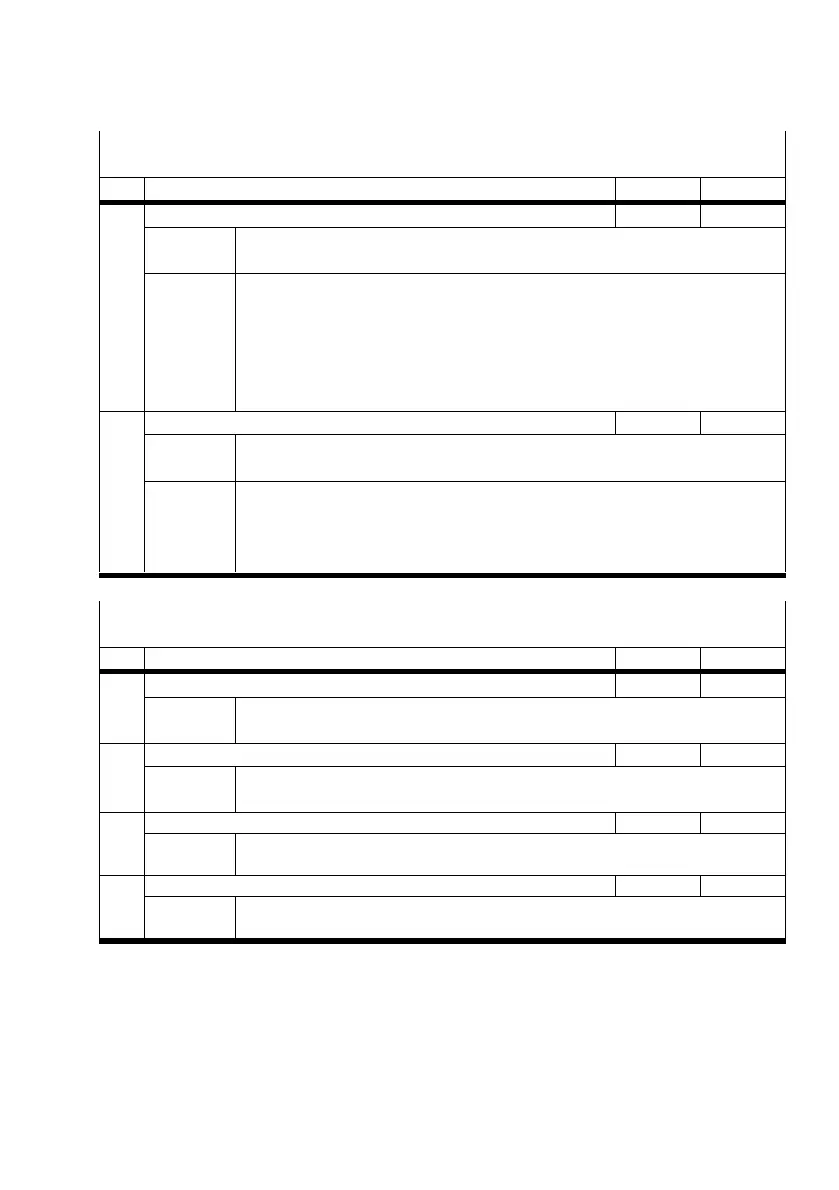

Group 1 – Execution error

CPX error group 101 (CPX-MMI: [Execution error] )

No. Message Error level Reset type

10 Homing not executed F1 R

Cause Drive with incremental displacement encoder is not referenced.

Measure Perform homing.

11 Homing not required F1 R

Cause Homing with absolute displacement encoder.

Measure Do not perform homing.

13

Wrong direction of movement during movement test F2 R

Cause Incorrect tubing connection to cylinder and valve.

Measure Check and correct the tubing connection.

14

Movement test not carried out F2 R

Cause Positioning command without valid movement test.

Measure Perform movement test (recommended) or skip.

Loading...

Loading...