6 Diagnostics and error handling

76 Festo – P.BE-CPX-CMAX-SYS-EN – en 2017-09b – English

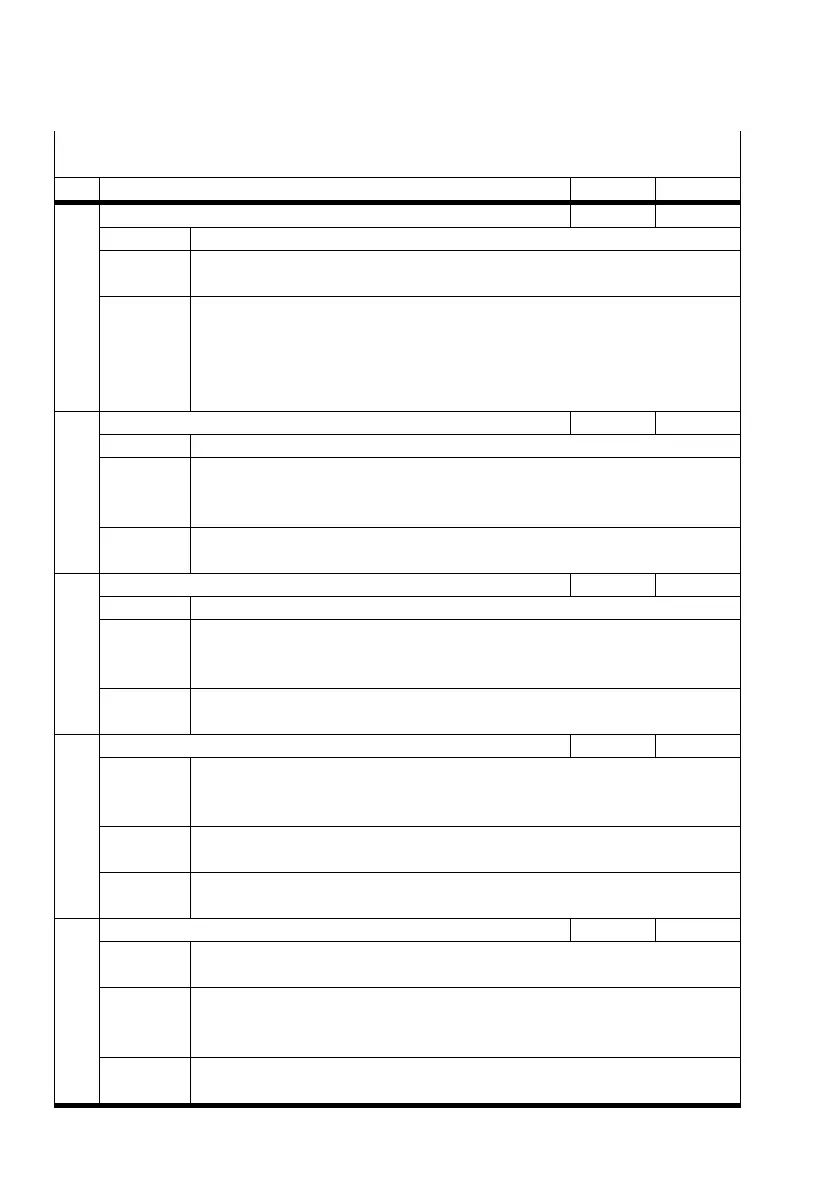

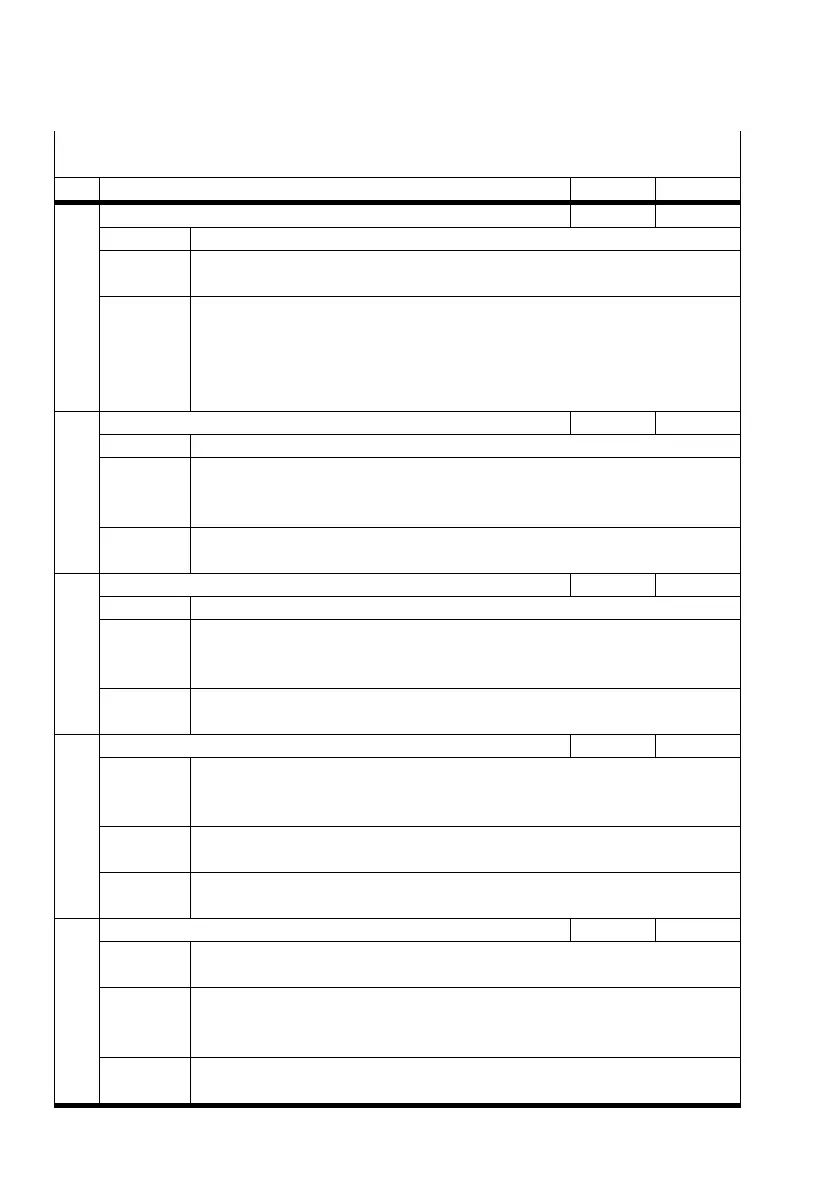

Group 3 − Control error

CPX error group 103 (CPX-MMI: [Control error] )

No. Reset typeError levelMessage

32 Target force outside the force limits F1 (W) R

Note Message can be parameterised alternatively as a warning (W) or error (F1).

Cause Target force outside the set force limits.

Measure Correct target force or force limit.

Cause The target force is larger than the maximum force that can be reached (the

maximum attainable target force determined by the CMAX may deviate from the

theoretical value calculated by the FCT).

Measure Correct target force, increase supply pressure, reduce moving load in vertical

structure, use larger drive.

33 Target position outside the software or hardware end positions F1 (W) R

Note Message can be parameterised alternatively as an error (F1) or warning (W).

Cause Target position is outside the set software end positions.

Measure Check and correct target position, software end positions and project zero

point.

Cause Target position is outside the reachable hardware end positions.

Measure Check and correct target position and project zero point.

34 Setpoint value in tracking mode outside the limit values W (F1) F (R)

Note Message can be parameterised alternatively as a warning (W) or error (F1).

Cause Setpoint position is outside the set software end positions.

Measure Check and correct setpoint position, software end positions and project zero

point.

Cause Setpoint position is outside the reachable hardware end positions.

Measure Check and correct setpoint position and project zero point.

35 Software end position passed W (F1) F (R)

Note The actual position has exceeded a software end position with active position

control, whereby a tolerance of 2 mm has been taken into account.

Message can be parameterised alternatively as a warning (W) or error (F1).

Cause The drive was pushed out of the valid range by an external force.

Measure Prevent external force, if possible.

Cause Controllers which are not optimally set can lead to considerable overshooting.

Measure Optimize controller, check parameterisation, perform identification again.

36 Software end position reached during force control F1 R

Note The actual position has exceeded a software end position with active force con

trol. A tolerance of 2 mm has been taken into account here.

Cause No workpiece.

Measure Check workpiece; check workpiece position.

Use record sequencing for return travel or stop.

Cause Software end positions can be reached in the desired sequence.

Measure Correct software end positions.

Loading...

Loading...