6 Diagnostics and error handling

Festo – P.BE-CPX-CMAX-SYS-EN – en 2017-09b – English 85

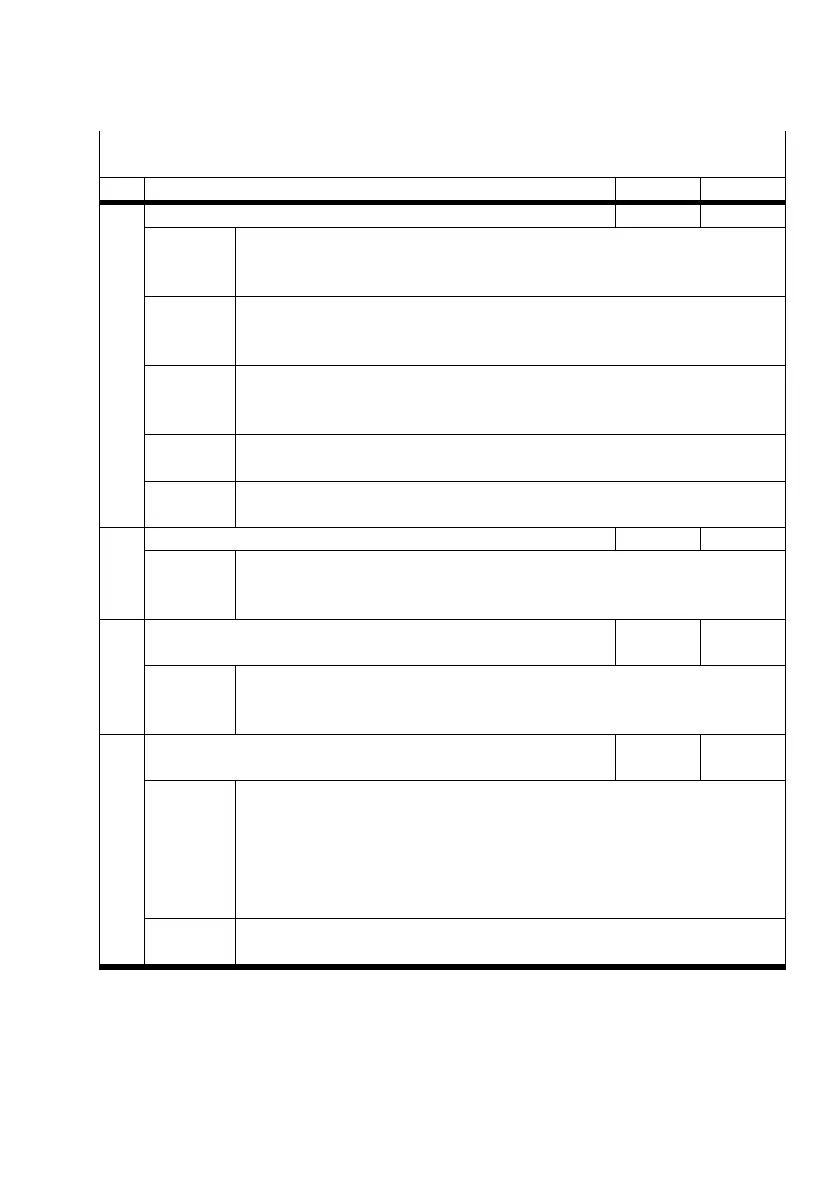

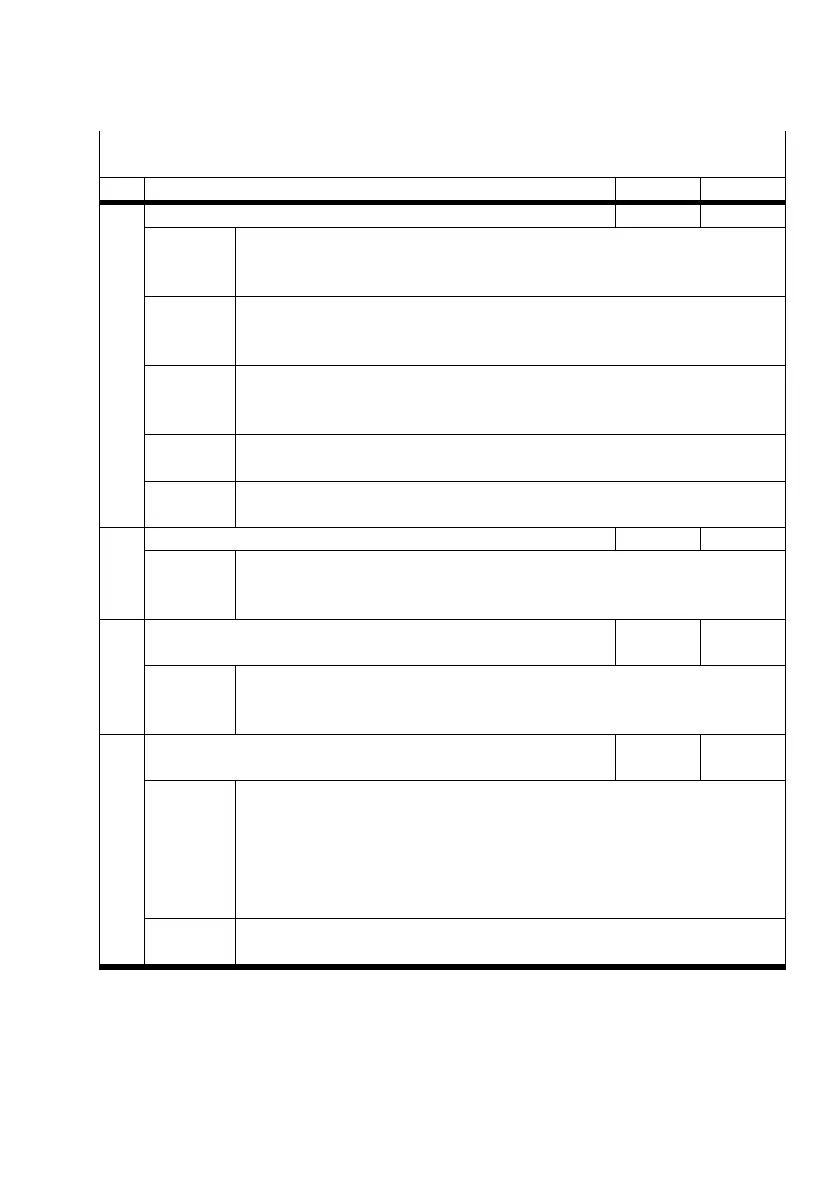

Group 8 – Displacement encoder error

CPX error group 108 (CPX-MMI: [Encoder error] )

No. Reset typeError levelMessage

82 Invalid measured values or displacement encoder faulty F2 F

Cause DGCI/DDLI: No magnet present.

Measure Check magnet on the displacement encoder, replace magnet holder if

defective.

Cause DGCI/DDLI: Several magnets present.

Measure Make sure that no external magnets are in close proximity to the

displacement encoder.

Cause DGCI/DDLI: Multiple pulses (e.g. due to vibrations).

Measure Check mounting.

Avoid vibration.

Cause DNCI: Sensor error.

Measure Replace sensor head in the DNCI.

Cause Potentiometer: Operating voltage drop below 12 V.

Measure Check operating voltage, check cables for short circuit and corrosion.

84 Reference position of the displacement encoder lost F2 N

Cause Although the drive has set the status “Referenced”, the displacement encoder/

sensor interface reports the status “Not referenced”.

Measure Reference again.

85 Operating voltage of displacement encoder/sensor interface

outside the tolerance range

F2 F

Cause Operating voltage of the displacement encoder too low.

Measure Check power supply.

Check lines on the axis string.

87 Defective displacement encoder cable or potentiometer in

electrical end position

F2 N

Cause Defective displacement encoder cable.

Measure Check power supply.

Check lines on the axis string.

Switching off/on may be required.

If this occurs repeatedly, replace the displacement encoder or sensor

interface.

Cause Displacement encoder in the electrical end position (potentiometer only).

Measure Move displacement encoder (potentiometer) from the end position.

Loading...

Loading...