Chapter 1: FT-50 System Overview

Industrial Dynamics Company, Ltd. Document 40272-0700 1-3

Fill Level Inspection Basics

The FT-50 Fill Level Inspection systems utilizes a Container Radiation

Profile Comparison Principle to create a radiation fingerprint of the

container.

To create a radiation profile a gamma beam is directed through the

container. Some of the radiation is blocked by the container material and

container’s contents while the remaining gammas emerge from the

opposite side of the container where they are measured by an gamma

detector.

The amount of radiation measured is the containers radiation profile, or

fingerprint, which is then compared against a Master Container Profile.

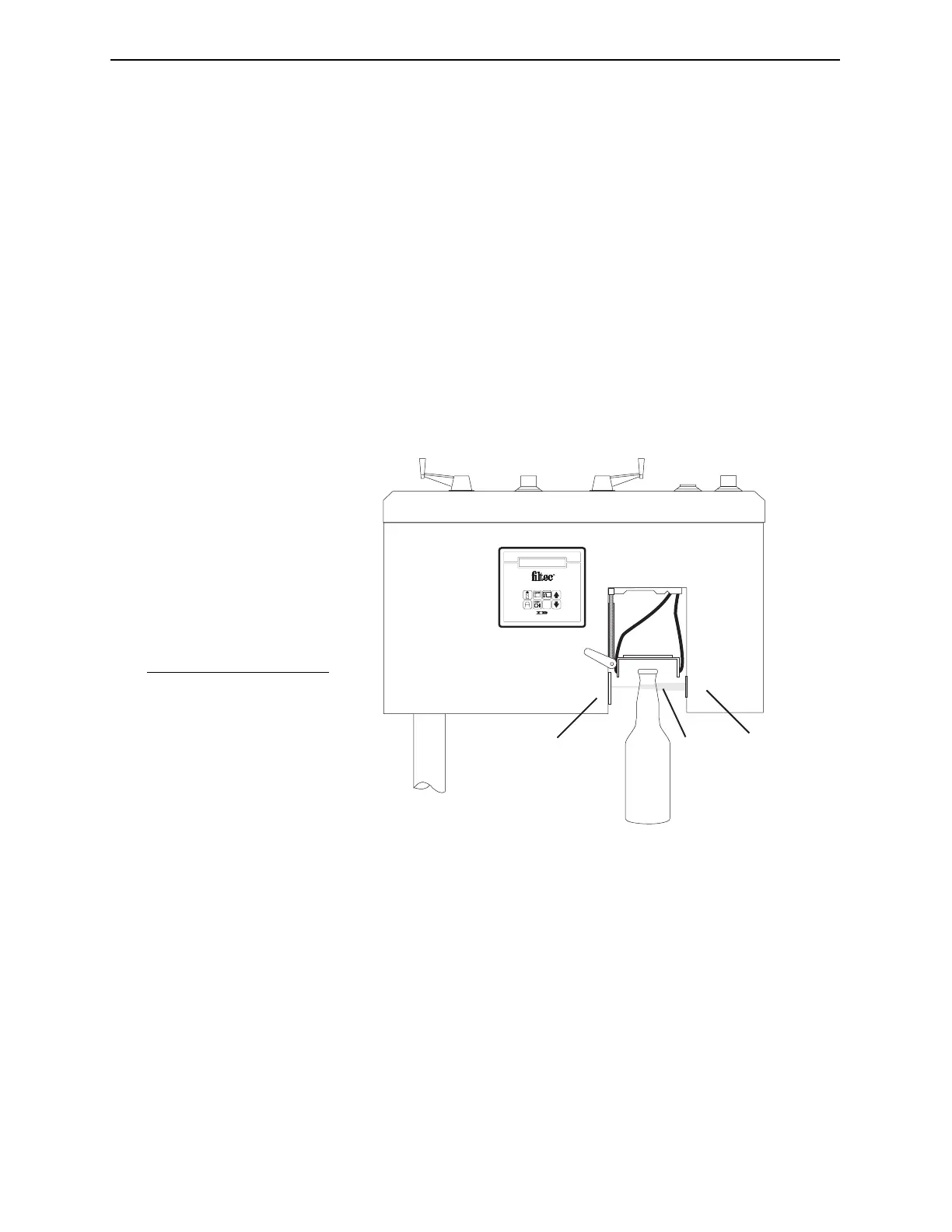

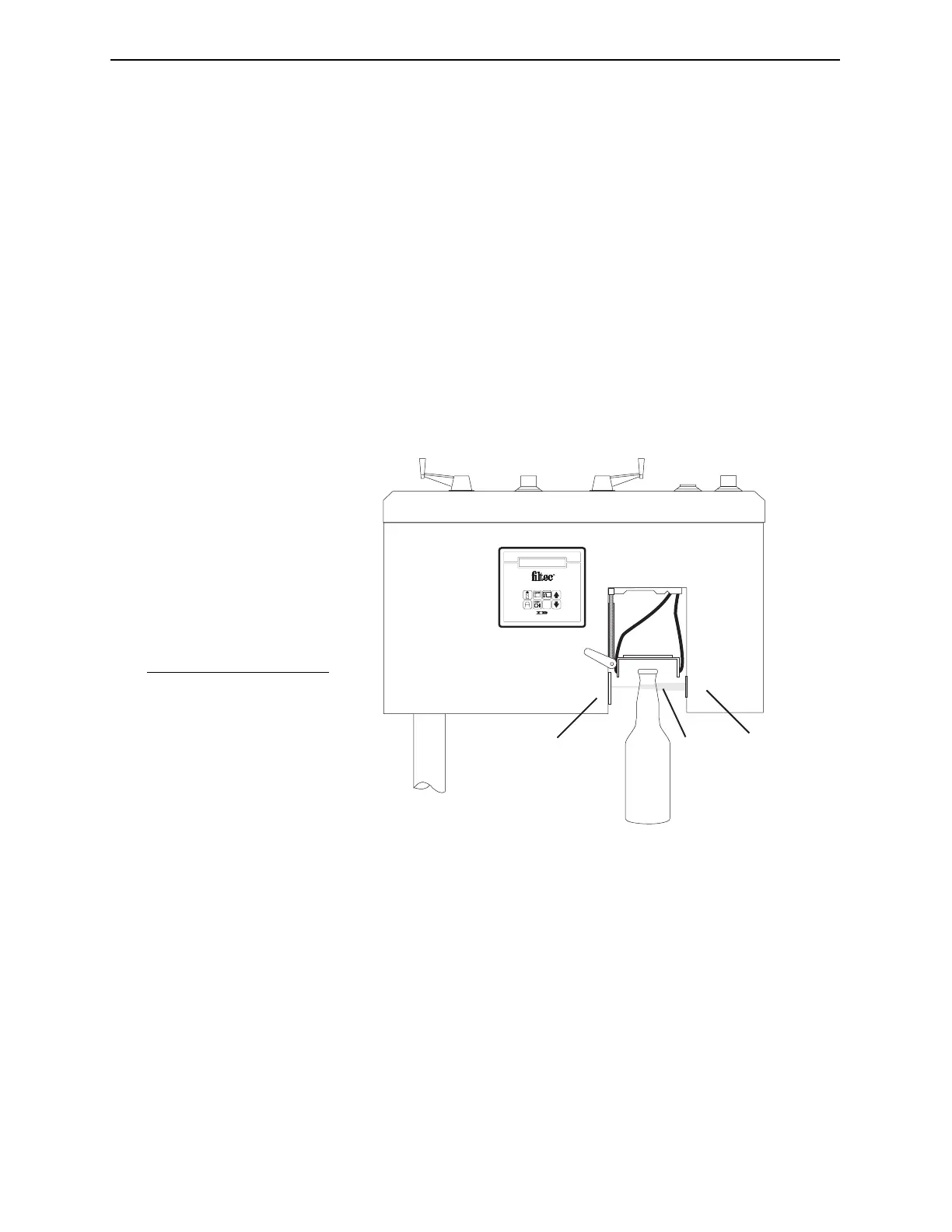

Figure 1-2.

Scanning the container.

To allow for slight variances in the fill level an underfill threshold or

overfill threshold is determined. These thresholds form the tolerance

range for deviation from the master profile. Any container with a gamma

count above the underfill threshold (higher gamma counts indicate there

is less product to absorb the gamma beam) is rejected as an underfill. Any

container with a gamma count below the overfill threshold (lower gamma

counts indicate there is more product to absorb the gamma beam) is

rejected as an overfill.

?

6

INDUSTRIAL DYNAMICS

Torrance, California USA

MODEL FT-50

FILL LEVEL INSPECTOR

4

3

5

1

2

1

32

No. Description

1 gamma Source

2 gamma Beam

3gamma Detector

Loading...

Loading...