FT-50 Fill Level Inspector Operation Guide

1-4 Industrial Dynamics Company, Ltd. Document 40272-0700

Rejection Control Basics

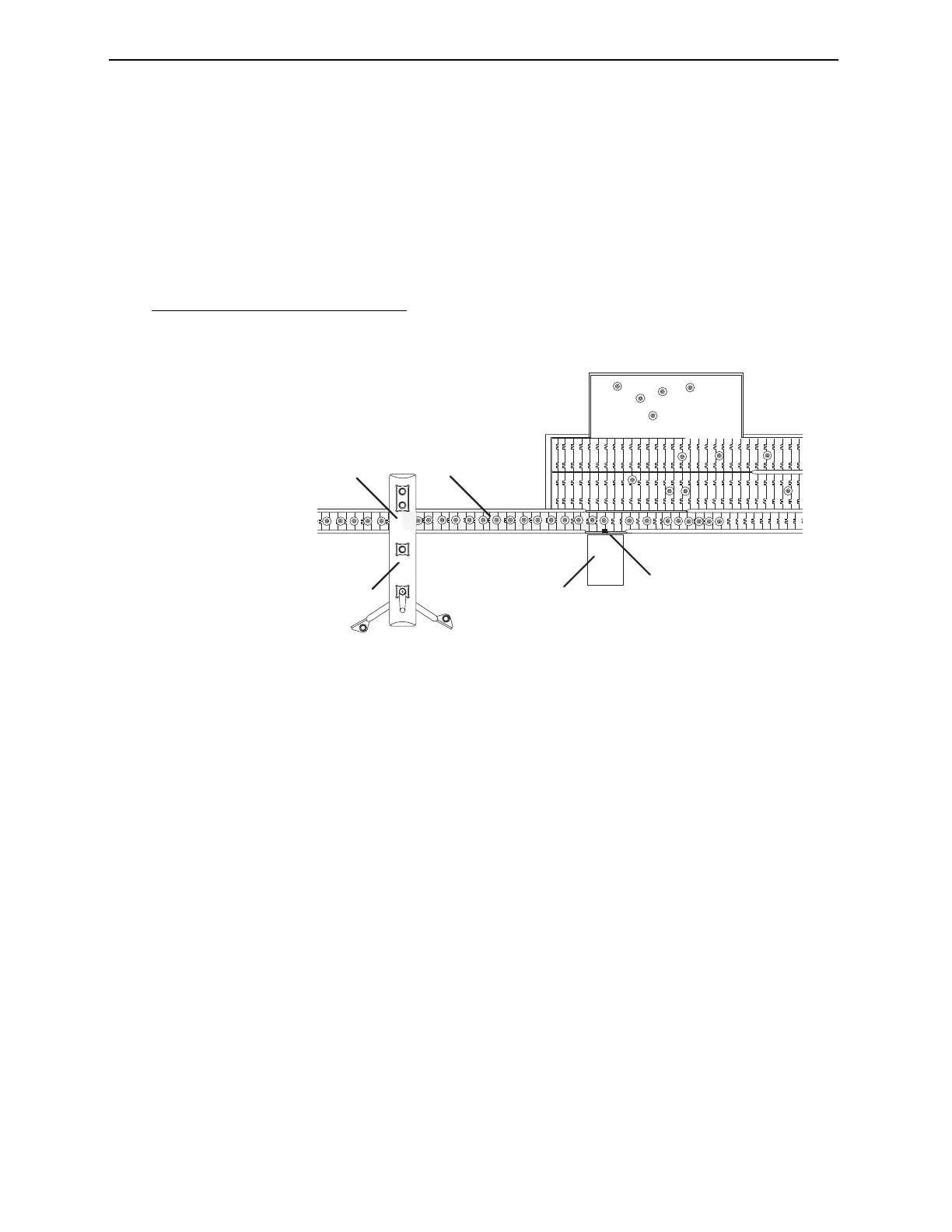

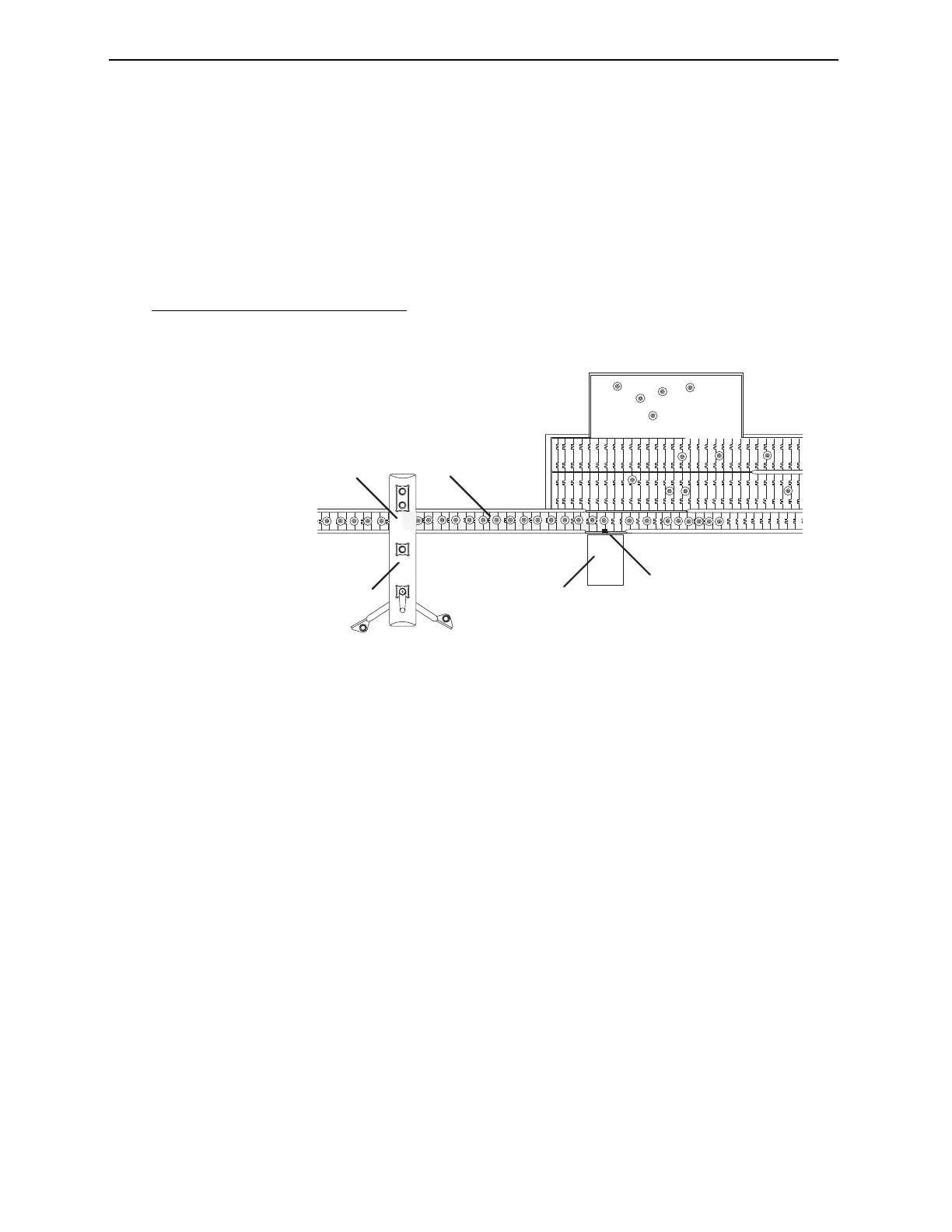

The FT-50 identifies and then tracks any container that fails inspection.

Tracking begins the moment the container crosses the inspection trigger

beam in the and ends when the container reaches the rejector centerline.

Figure 1-3.

Tracking containers that fail inspection.

To maintain container tracking and to synchronize the rejector to the

conveyor, the FT-50 uses a high-resolution encoder coupled directly to the

conveyor drive sprocket. The encoder sends timing pulses to the FT-50

which uses the pulses to determine the container’s position as it moves

along the conveyor between the FT-50 and the rejector. When the

container reaches the rejector centerline the FT-50 emits a reject signal

which activates the rejector and removes the container from the

production line.

1

2

3

5

4

X

No. Description

1FT-50

2 Inspection Trigger Location

3 Extent of Tracking Area (gray)

4 Rejector Centerline

5 Rejector

Loading...

Loading...