DC100 MAX Digital Dispenser Operating Manual

© 2023 Fisnar - 4 - DC100 MAX Rev 4

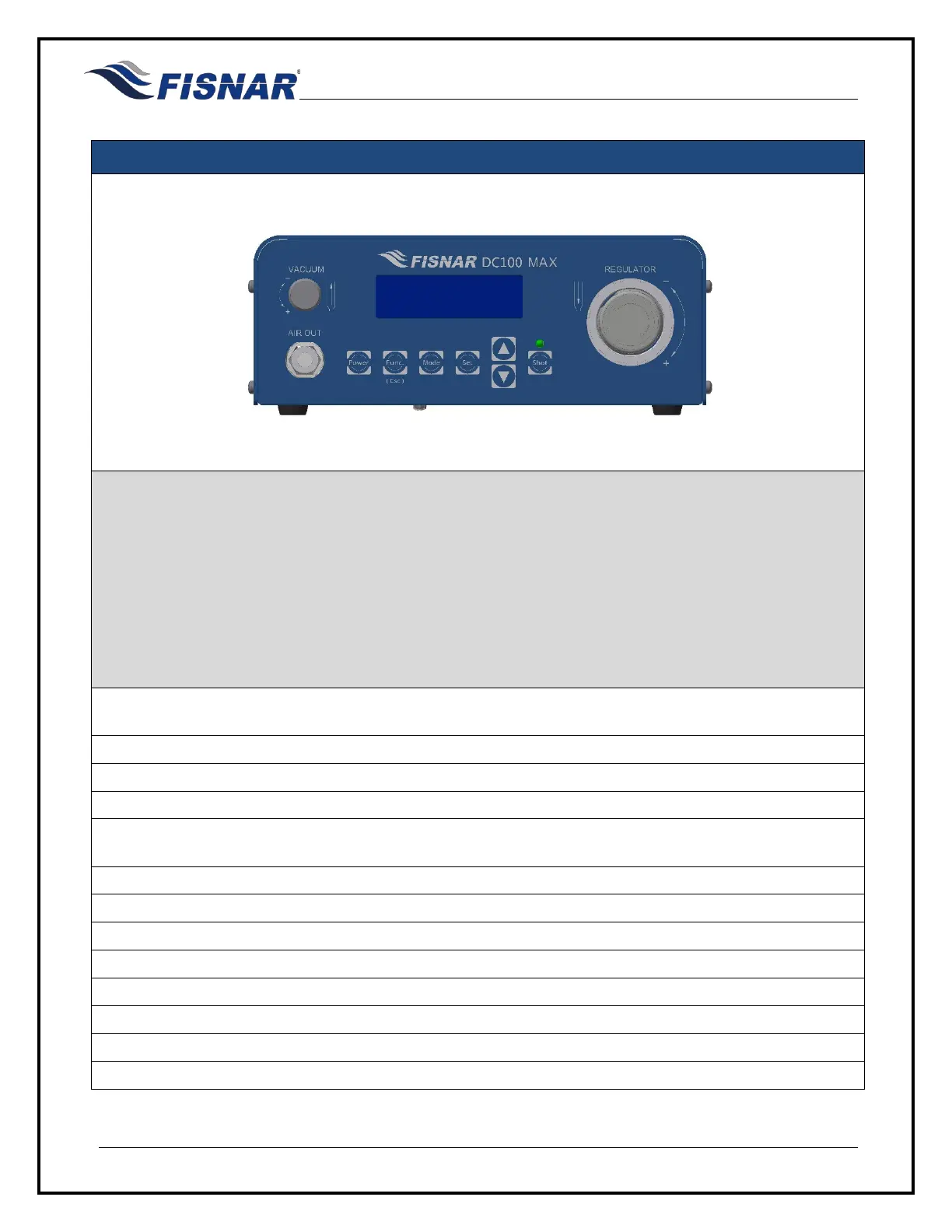

Model DC100 MAX Digital Dispenser

The DC100 MAX is a versatile, high precision dispenser designed to achieve exceptional levels

of process stability in critical dispense

applications: from microdot deposits and precise

beads, to potting and encapsulation. The advanced user-friendly dispense software features

a wide range of intelligent functions, allowing the user to maximize accuracy, control and

monitoring of their dispensing process.

Programmable alarms can be set to notify the user when fluid material life has ended, or when

fluctuations in the dispensing pressure have occurred. The sequence function enables the

dispense time to be changed at pre-set time intervals or shots. This ensu

dispense results from the start to finish of the process, due to fluid viscosity changes or

reduction in the syringe fluid level being accounted for.

• Digital dispensing parameters, precision regulator, vacuum control and high flow solenoid ensure

high accuracy repeatable dispense results.

• 16 programmable memory slots

• 5 dispense modes (Purge, Teach, Timed, Time+, Cycle)

• Multilingual Display, digitally displaying dispense time, pressure and vacuum

• 13 channel I/O circuit for external program change, dispense actuation, machine status and alarm

monitoring & signaling.

• I/O test mode

• Momentary or Latching shot actuation signal

• RS232 port for external control, monitoring and programming of dispense parameters

• Internal pressure and vacuum calibration function

• Operator lockout function prevents dispense programs and functions from being modified

• Pressure and Vacuum alarm for maintaining consistent dispense parameters

•

Auto-purge cycle and glue alarm prevents premature curing when dispensing 2K fluid materials

•

Option to attach barcode scanner for touch-free program selection and dispense actuation

Loading...

Loading...