Assembly

5.1 Preparatory work

M4602-02en Edition 09/2022 31

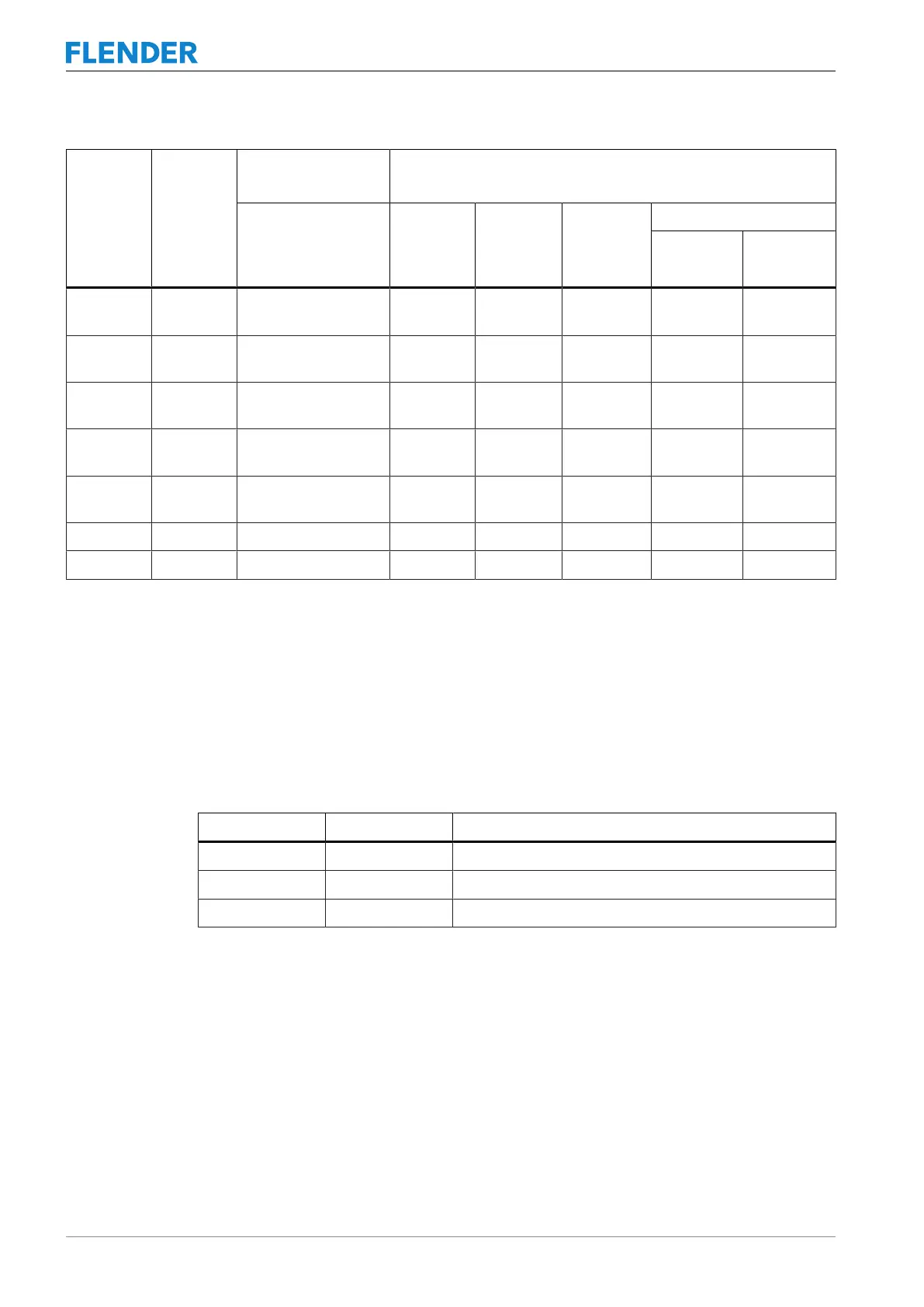

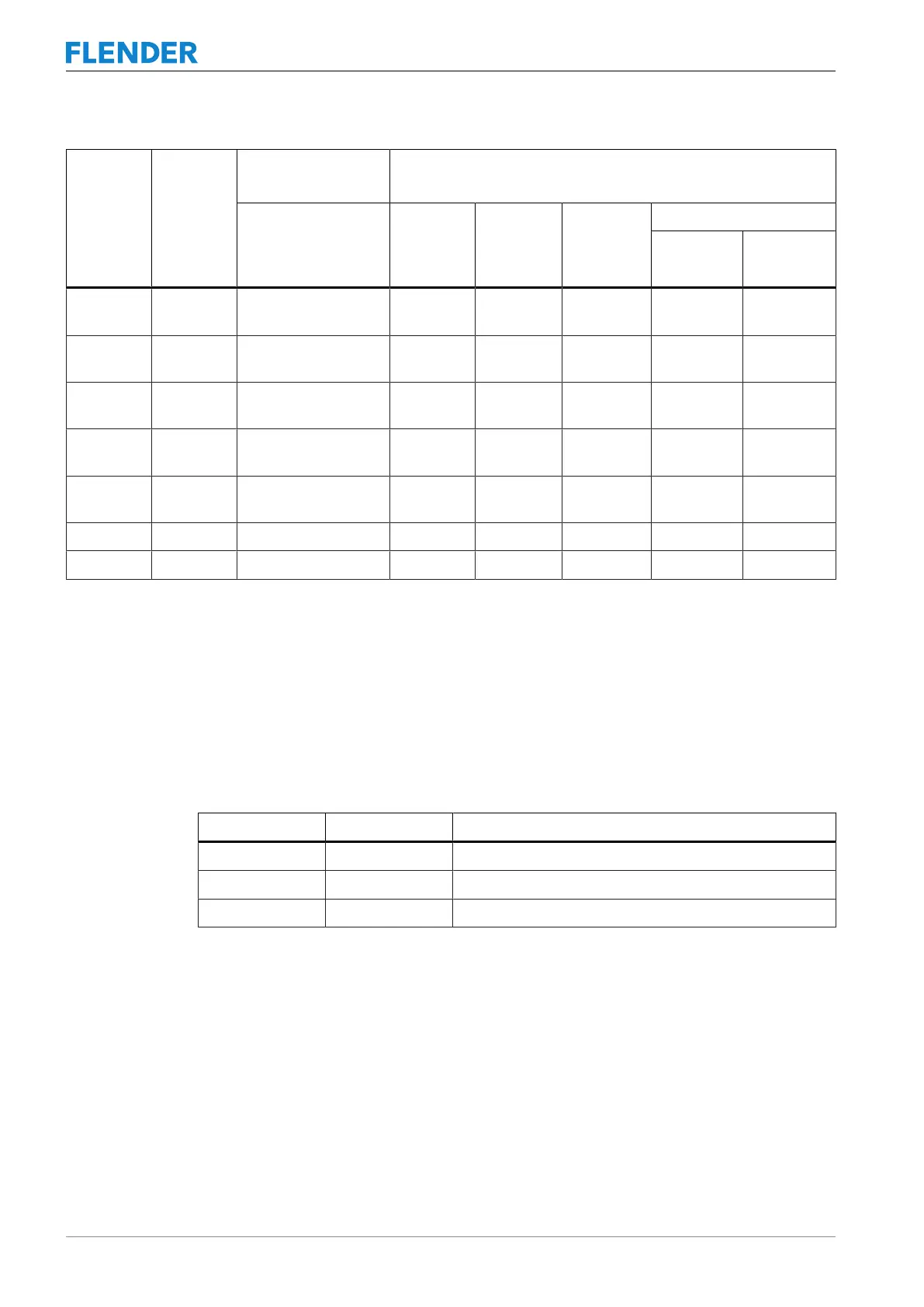

FLUDEX

Size

N-EUPEX

Size

Maximum bore D1

1)

mm

Maximum bore D2

1)

mm

Part 120 Part 1

FNA

Part 11

FND

Part 11, 32

FNDS

SB (32) /

HB (11)

Part 32 (brake drum)

FNDB

D x B

D

2

370 180 80 80 70 80 315 x 118

400 x 150

80

90

425 200 100 85 80 80 315 x 118

400 x 150

80

90

490 225 110 90 90 90 400 x 150

500 x 190

90

110

565 250 120 100 100 100 400 x 150

500 x 190

100

110

655 315 135 120 110 100 500 x 190

630 x 236

110

140

755 350 150 140 120 140 630 x 236 140

887 440 170 160 130 140 710 x 265 160

Table5-2: Maximum bores for the hub parts

1)

Maximum bore for parallel keyway in accordance with DIN6885/1.

5.1.2 Mill the parallel keyway5.1 Preparatory work

Position of the parallel keyway

The table below states the required position for the parallel keyway in the coupling parts.

Coupling part Coupling Position of the parallel keyway

1 N‑EUPEX Centred between the flexible element bridges

11 / 32 FLUDEX Beneath a threaded hole

120 FLUDEX 90° to the threaded hole

Table5-3: Position of the parallel keyway

Applicable standards

• Machine the parallel keyway according to DIN6885/1ISOJS9 .

• If you want to mill a parallel keyway that does not correspond to DIN6885/1, please con-

sult Flender.

5.1.3 Machining an axial locking mechanism5.1 Preparatory work

The coupling part is secured by a set screw or an end plate to prevent axial movements.

Loading...

Loading...