Assembly

5.1 Preparatory work

M4602-02en Edition 09/2022 33

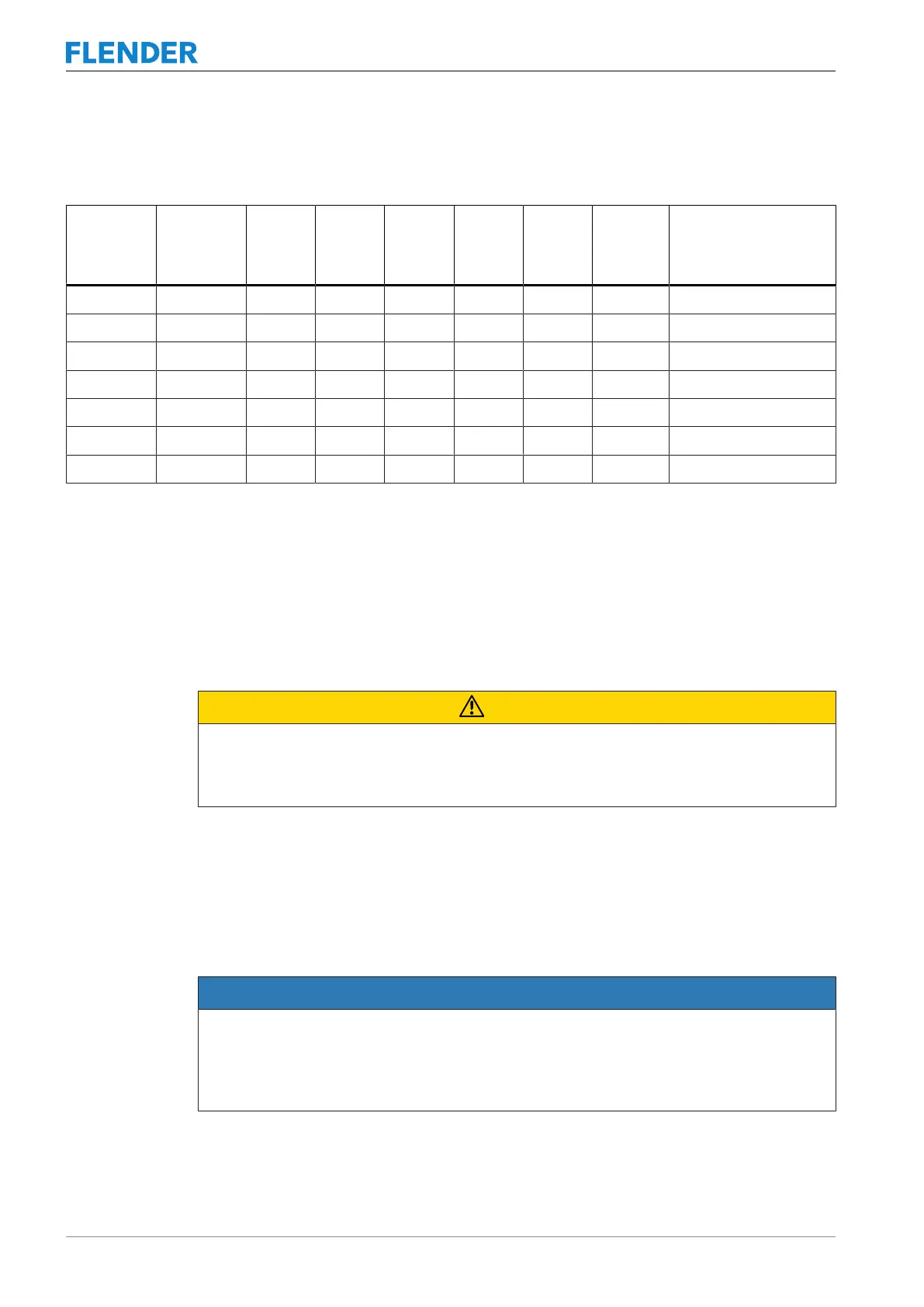

The following table contains the values for the diameter and axial position of the threaded

hole depending on the coupling size.

FLUDEX

Size

N-EUPEX

Size d1 e1

mm

e2

mm

e5

mm

e6

mm

e7

mm

Tightening torque T

A

of the set screws

Nm

370 180 M12 23 16 30 25 85 25

425 200 M12 25 20 40 25 85 25

490 225 M12 25 22 40 30 85 25

565 250 M16 23 24 50 50 85 70

655 315 M16 50 35 60 75 85 70

755 350 M20 40 40 70 75 85 130

887 440 M24 50 60 90 75 85 230

Table5-4: Diameter and axial position of the threaded hole, tightening torque

Apply the specified tightening torques as listed in Section Tightening procedure (Page81).

Position of the threaded hole with respect to the parallel keyway

Position the threaded hole for the set screw on the parallel keyway.

Selection of the set screw

CAUTION

Physical injury

Risk of injury from protruding set screw.

• Please observe the information about selecting the set screw.

Use set screws in accordance with ISO 4029 with a toothed cup point. The size of the set

screw is determined by the bore made. The set screw should fill out the threaded hole as

much as possible and must not protrude beyond the hub.

5.1.4 Balancing the coupling5.1 Preparatory work

NOTICE

Property damage to coupling part 1 (1)

If you completely drill through the base of a flexible element pocket on coupling part 1 (1),

then coupling part 1 (1) is no longer allowed to be used for operation.

• Please observe the stipulations about machining the balancing bore.

Loading...

Loading...