Maintenance

8.1 Maintenance intervals

56 Edition 09/2022 M4602-02en

Check the torsional backlash between the coupling parts at the specified maintenance inter-

vals. The maximum permissible torsional backlash for the various coupling sizes can be

found in section Maximum permissible torsional backlash (Page56).

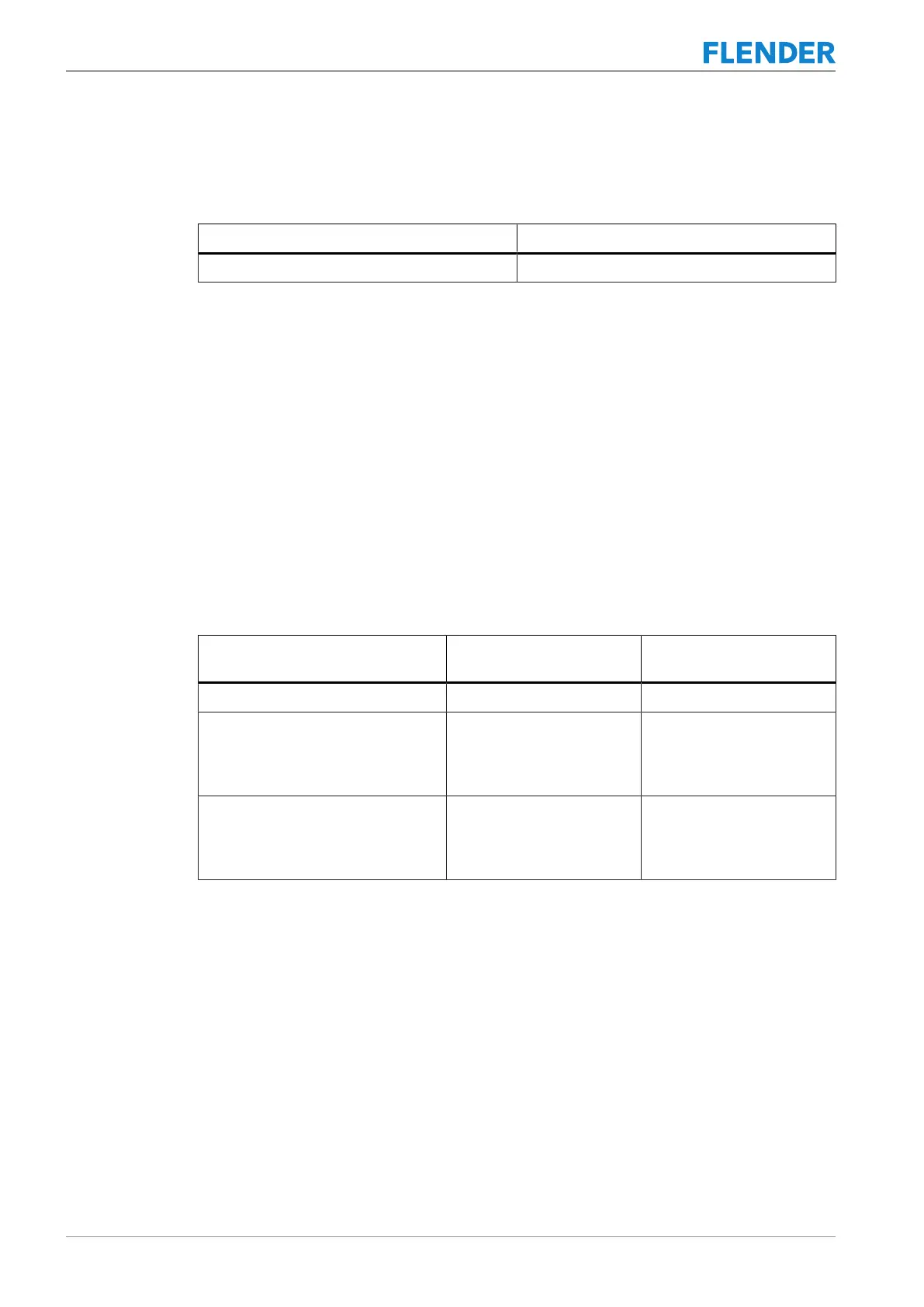

Initial maintenance Follow-up maintenance

3 months after commissioning Every 12months

Table8-1: Maintenance intervals

Shorter maintenance intervals

If necessary, set shorter maintenance intervals depending on actual wear.

8.1.2 FLUDEX coupling8.1 Maintenance intervals

Operating fluid

Change the operating fluid at the specified maintenance intervals.

When changing the operating fluid, ensure that the old operating liquid is drained off com-

pletely. This is possible via the openings of the fusible safety plug (103) or via the opening of

the screw plug (163). Drain the residual oil from the prechamber via the screw plug (173).

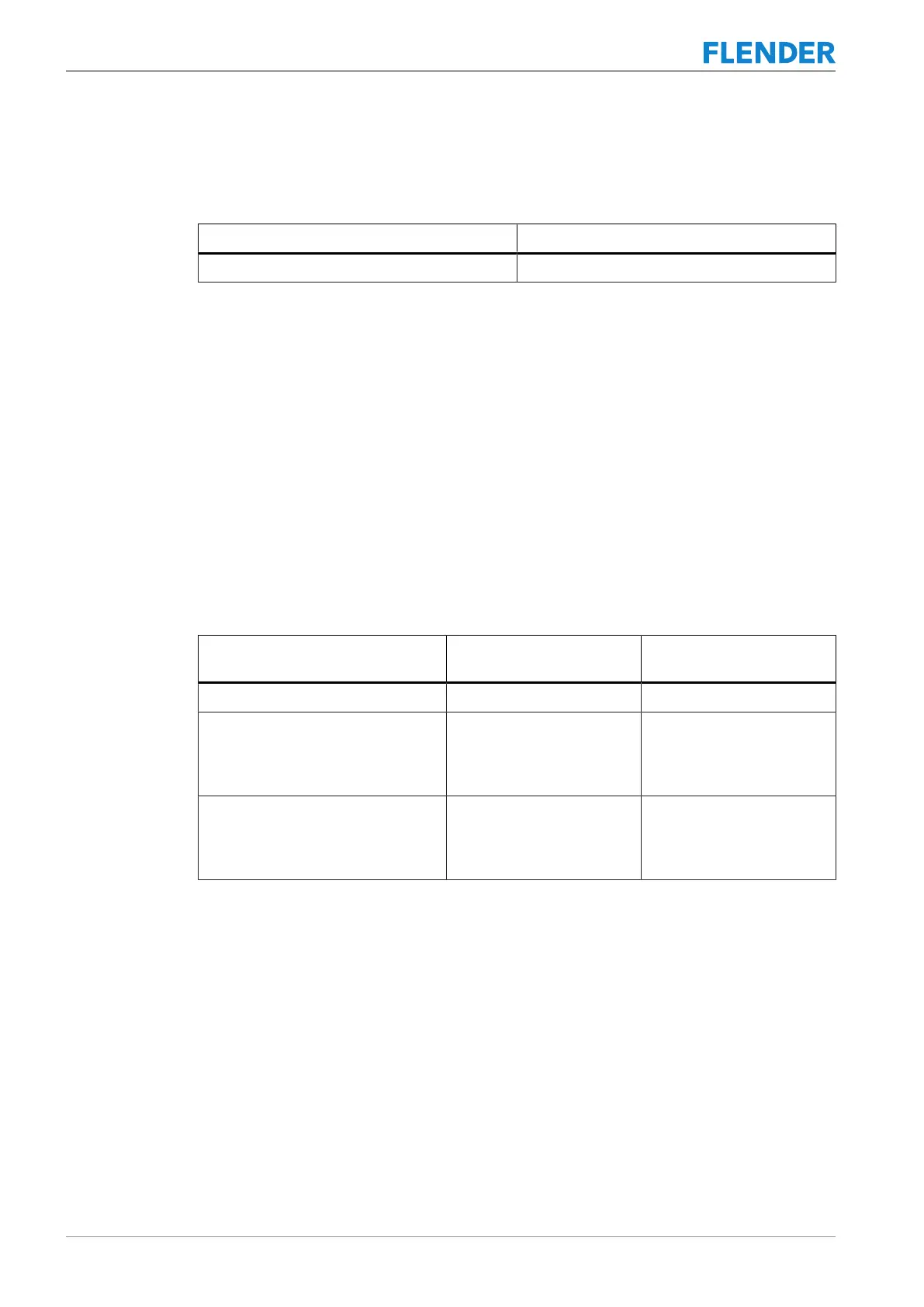

Operating temperature/ Special

measures

maximum operating hours

of the operating fluid

maximum years of service

of the operating fluid

maximum 80°C 10000 5

maximum 95°C

or frequent temperature peaks above

100°C:

Use of Viton seals required

5000 2

over 95°C

only suitable synthetic oils are per-

missible

Use of Viton seals required

according to the specifica-

tions of the manufacturer of

the operating fluid

according to the specifica-

tions of the manufacturer of

the operating fluid

Table8-2: Operating temperatures, operating hours and years of use

In consultation with the manufacturer of the operating fluid, modified operating conditions

and change intervals are permissible.

Shaft sealing rings

For FLUDEX couplings operated with oil, no maintenance interval needs to be observed for

the shaft sealing rings.

8.2 Maximum permissible torsional backlash8.2 Maximum permissible torsional backlash

1. In order to calculate the torsional backlash, rotate one coupling part without applying

torque up to the stop.

Loading...

Loading...