FRICK

®

QUANTUM™ LX COMPRESSOR CONTROL PANEL S90-020 M

MAINTENANCE Page 45

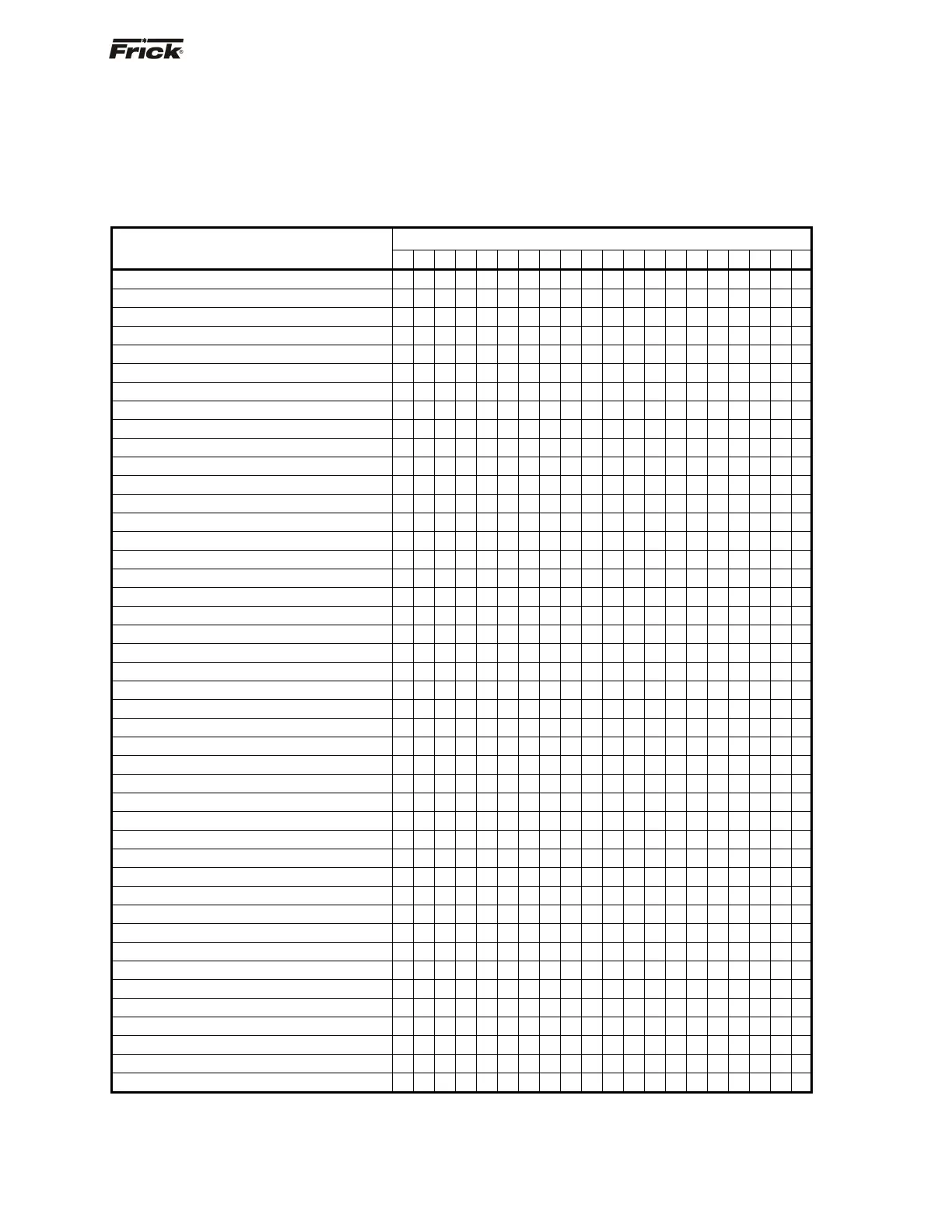

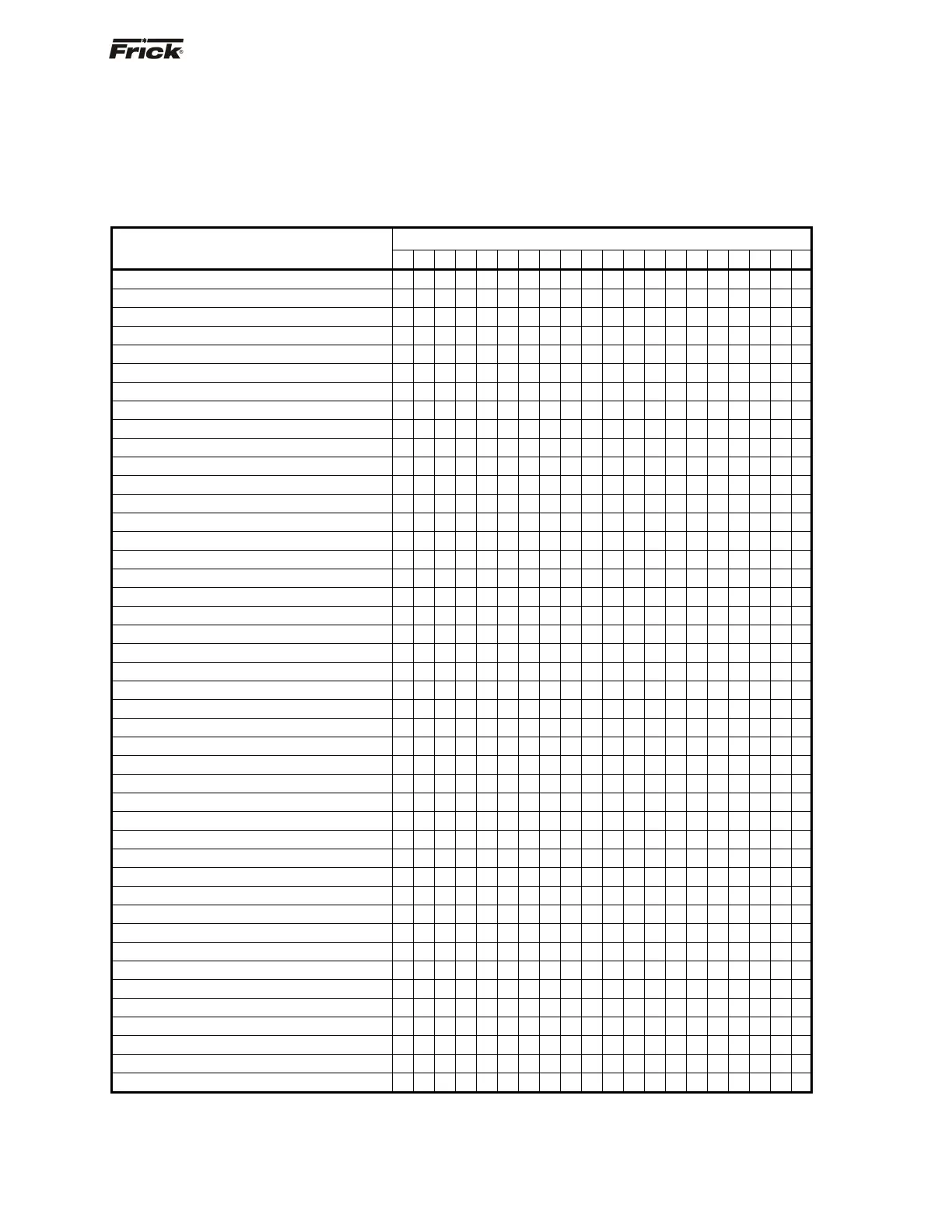

SETPOINT DATA SHEETS

In most cases, updating software on the Quantum™ LX panel will require clearing the current setpoints and data stored in the

nonvolatile memory on the main board. It is suggested that the operator first record all control setpoints prior to performing

program upgrades. The setpoint data sheets are useful for recording this information.

OPERATING VALUES

User Defined Setpoints

Channel

1234567891011121314 15 16 17 181920

Capactiy Slide Position

Volume Slide Position

Suction Pressure

Discharge Pressure

Compressor Oil Pressure

Main Oil Injection Pressure

Economizer Pressure

Filter Pressure

Intermediate Pressure

Balance Piston Pressure

System Discharge Pressure

Suction Temperature

Discharge Temperature

Compressor Oil Temperature

Oil Separator Temperature

Process/Brine Temperature Leaving

Process/Brine Temperature Entering

Motor Current

RPM

Auxiliary Analog 1

Auxiliary Analog 2

Auxiliary Analog 3

Auxiliary Analog 4

Auxiliary Analog 5

Auxiliary Analog 6

Auxiliary Analog 7

Auxiliary Analog 8

Auxiliary Analog 9

Auxiliary Analog 10

Auxiliary Analog 11

Auxiliary Analog 12

Auxiliary Analog 13

Auxiliary Analog 14

Auxiliary Analog 15

Auxiliary Analog 16

Auxiliary Analog 17

Auxiliary Analog 18

Auxiliary Analog 19

Auxiliary Analog 20

Compressor Vibration - Suction

Compressor Vibration - Discharge

Motor Vibration - Shaft Side

Motor Vibration - Opposite Shaft Side

None

Loading...

Loading...