QUANTUM

™

LX EVAPORATOR CONTROL PANEL

COMMUNICATIONS SETUP

090.610-CS (MAY 2016)

Page 35

SECTION 4

MODBUS

®

PROTOCOL

Changing a setpoint causes the Quantum™ to

save the new setpoint to nonvolatile memory.

Be careful not to continuously request a setpoint

change. Keeping the Quantum™ busy writing to

memory will interfere with the Quantum™ com-

municating to its I/O boards. A communication

failure to an I/O board will cause the Evapora-

tor to shutdown. For more detail and a list of

the data, reference the Quantum™ Data Table

section of this manual. For details about the ac-

tual protocol, reference the Modicon website at

http://www.modbus.com.

MODBUS® TCP/IP (Ethernet)

TCP/IP is the common transport protocol of the

Internet and is actually a set of layered proto-

cols, providing a reliable data transport highway

between Quantum™ LX panels and an Ethernet

network. Ethernet has become the standard for

factory networking, replacing many of the data-

bus systems used in the past.

MODBUS® TCP/IP simply takes the MODBUS®

instruction set and transparently wraps TCP/

IP around it. Unlike MODBUS® ASCII and RTU,

there no parameters that need to be set (such as

baud rate, data bits, etc.).

NOTE: When using Modicon Setup Software,

ensure that:

• Head number = Rack Position (position

of Ethernet card in its rack)

• Socket # = 502

Frick® Controls utilizes function codes 3 (Read),

6 (Write) and 16 (Multiple Write) of the TCP/IP

protocol. Use port 502 for Modbus TCP/IP com-

munications. The value used for the Modbus ID

must be greater than zero.

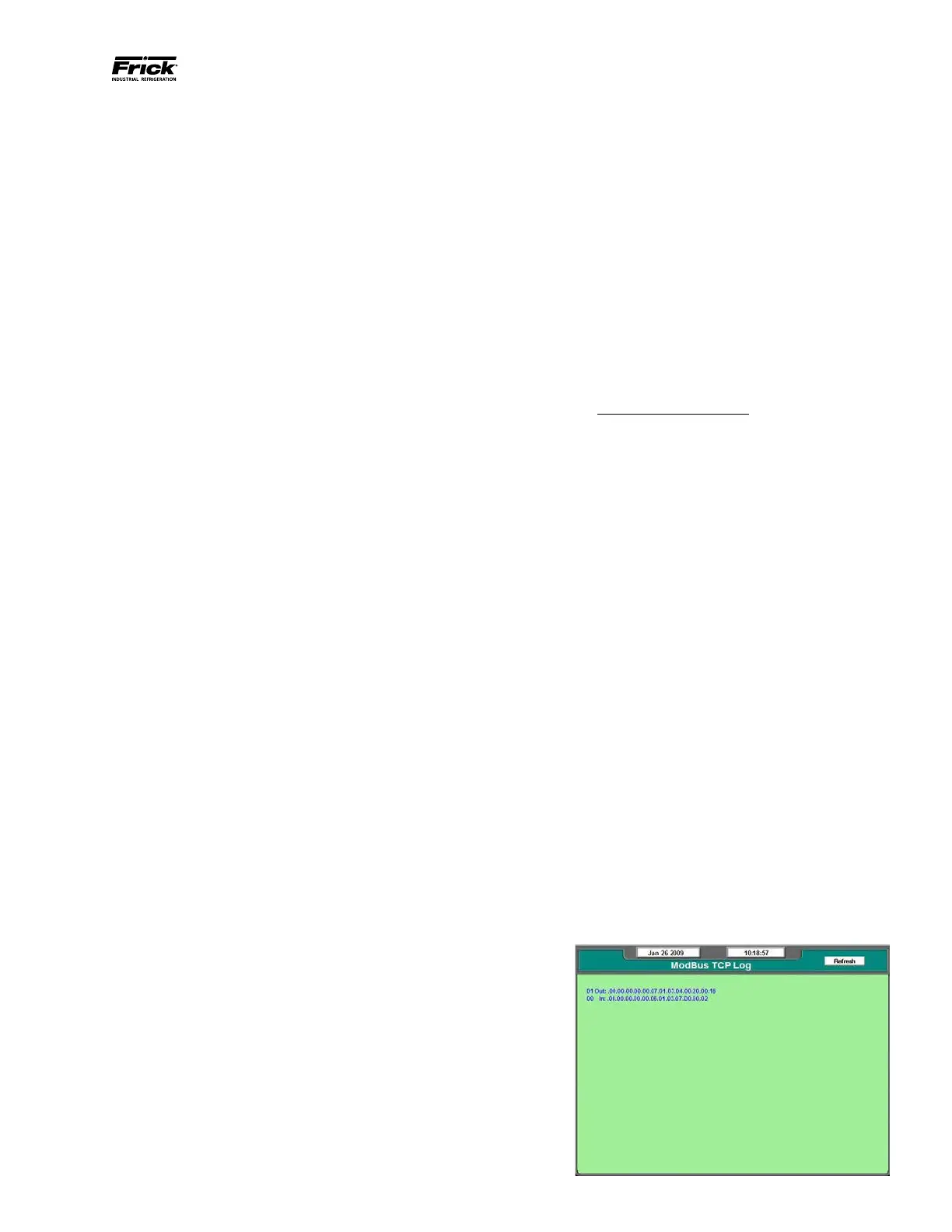

MODBUS® TCP LOG

MODBUS® Protocol

General Description

MODBUS® Protocol is a messaging structure de-

veloped by Modicon in 1979, used to establish

master-slave/client-server communication be-

tween intelligent devices. It is a standard, truly

open and the most widely used network protocol

in the industrial manufacturing environment. The

MODBUS® protocol provides an industry stan-

dard method that MODBUS® devices use for

parsing messages.

Since MODBUS® protocol is a messaging struc-

ture, it is independent of the underlying physical

layer. It is traditionally implemented using RS-

232, RS-422, or RS-485 communications hard-

ware. With the Quantum™ LX, MODBUS® TCP

can also be utilized as it applies to Ethernet net-

works.

The Quantum™ controller is setup to commu-

nicate on standard MODBUS® networks using

either ASCII (American Standard Code for Infor-

mation Interchange), RTU or TCP/IP.

The Quantum™ provides the capability to inter-

face with other devices that support serial data

communications using the MODBUS® protocol.

This is a Master / Slave multi-drop communica-

tion method whereby the Quantum™ is setup to

be a MODBUS® Slave. The customer’s PLC (Pro-

grammable Logic Controller) or DCS (Data Com-

munications System, such as a desktop or laptop

computer) must be setup as a MODBUS® Master.

The Master initiates the reading and writing of

data (queries) to a Quantum™. The Quantum™

does not generate its own data, it will only reply

to a request by the Master.

The Quantum™ ID number is used as the MOD-

BUS® Slave address (for ASCII and RTU). The

Master uses Function Code 3 (Read Holding Reg-

isters) to send a request to read data from the

Quantum™. The Master uses Function Code 6

(Load Register) to request to change a setpoint

or to send a command. Up to one hundred and

twenty-ve (125) data elements can be read with

one read request.

The address references are numbered rela-

tive to the Frick® addresses in the Quantum™

Data Table (see MODBUS Addressing Note in the

Quantum™ Data Table section of this manual for

additional information). The Quantum™ only ac-

cepts one value with a Load Register request.

Loading...

Loading...