RB-RBC-IOMM-2015-1

Fulton Ltd

Page 7

INSTALLATION - 2

2.5 FLUE OUTLET

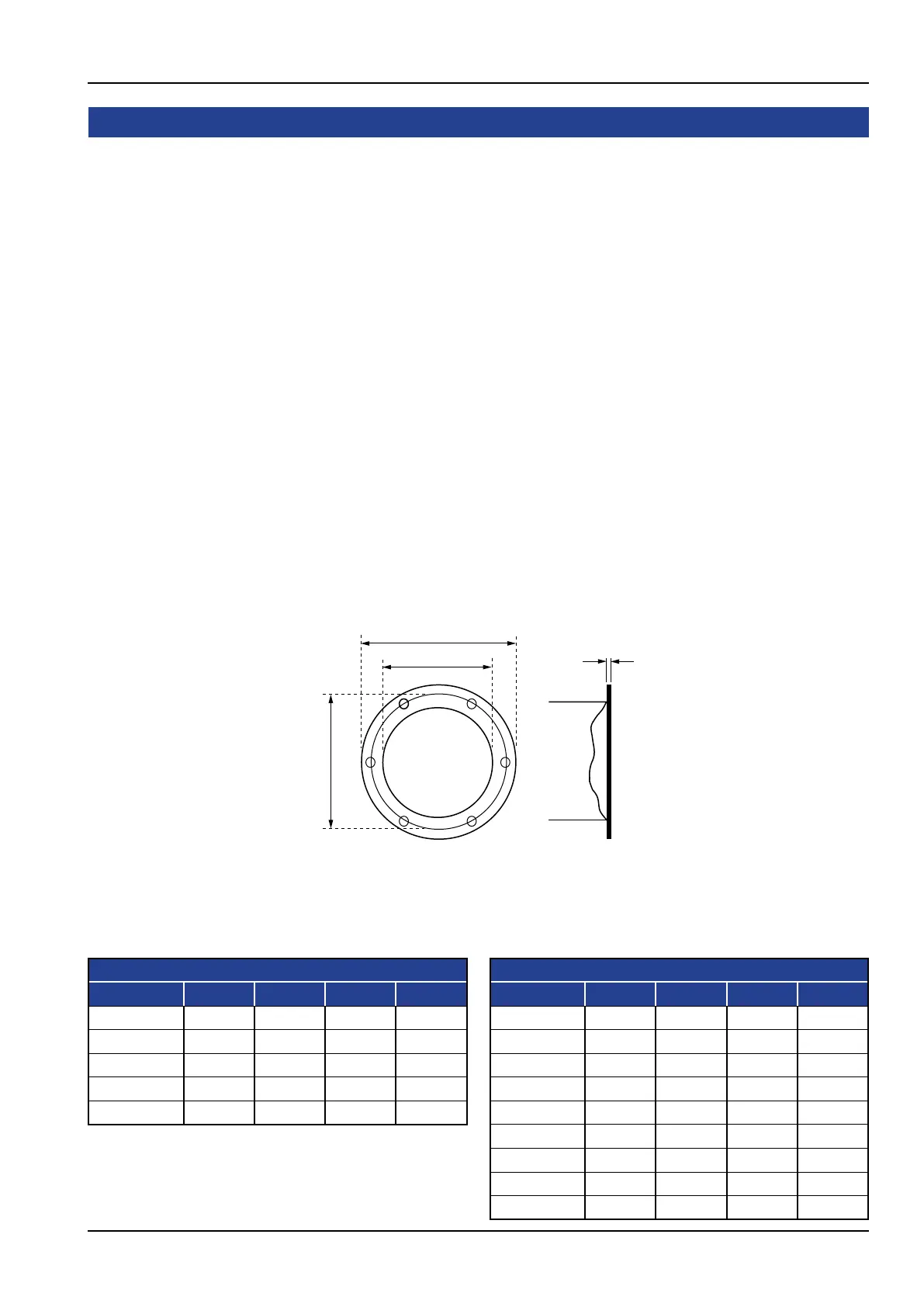

Figure. 3 - Boiler Flue Flange

Theheightandtypeofuewillbesubjecttolocalplanningregulationsandapprovals,andtothe

requirements of the Clean Air Act or similar local regulations.

Note: Before erecting a ue, Public Health Authority and Planning permission must be obtained.

Thefollowinginformationisintendedtoprovideassistancewheretheinstallationofasimpleue

is required.Wheremulti-boileruesarenecessary,ordifcultiescouldbeexperienced,specialist

advice must be obtained.

Boilersarettedwithaangedueoutlet.Theuemanufacturer/installermustbeconsultedatan

earlystagetoensureacorrectmatingcomponentforueconnection(seeFigure.3).

Theuediametermustbethesameorlargerthantheboilerueoutlet.Areductioninue

diameter will cause additional resistance which could have an adverse effect on combustion.

Note: Avoid tting 90° short radius elbows, 90° tees and long horizontal runs wherever possible.

Note: All horizontal ue runs should have a rising pitch of 15° minimum to prevent condensate build-up and

subsequent corrosion.

Note: Oil-red boiler installations are generally more critical because of the sulphur content in the fuel and the

higher dew-point temperature.

Note: Specialist advice should be obtained on ue material and insulation.

A

B

C

12 mm

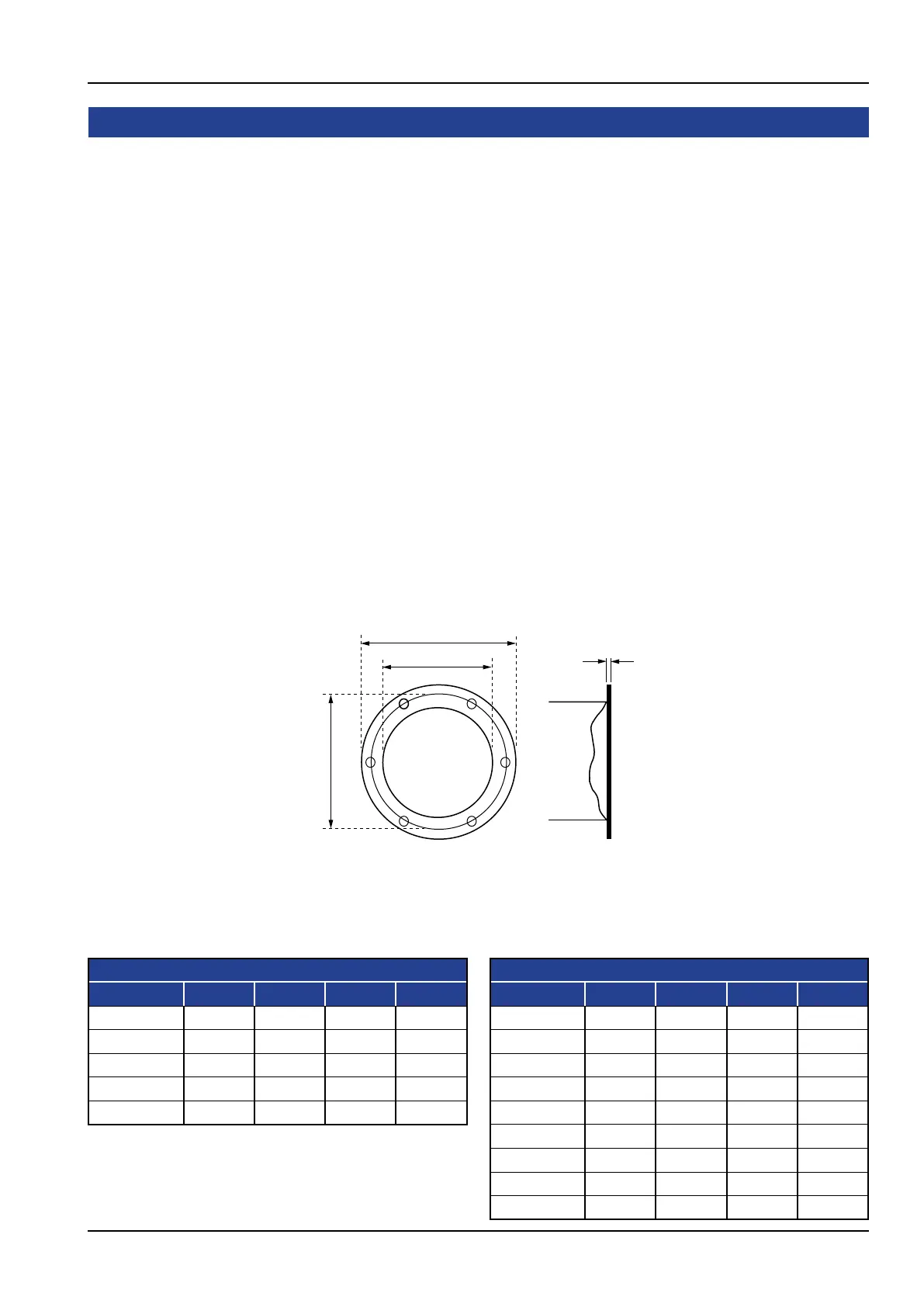

RBC Flue Connection

Holes 15mm dia. equi-spaced

Material mild steel

RB Flange

Model A B C (PCD) Holes

1600 400 300 360 6

2600 450 350 410 6

3400 550 450 510 6

4800 600 500 560 8

5500 650 550 610 8

RBC Flange

Model A B C (PCD) Holes

600 350 250 310 6

750 400 300 360 6

1000 400 300 360 6

1250 450 350 410 6

1500 500 400 460 6

1850 550 450 510 6

2100 550 450 510 6

2500 600 500 560 8

3000 650 550 610 8

Loading...

Loading...