RB-RBC-IOMM-2015-1

Fulton Ltd

Page 11

INSTALLATION - 2

2.9 WATER SUPPLY

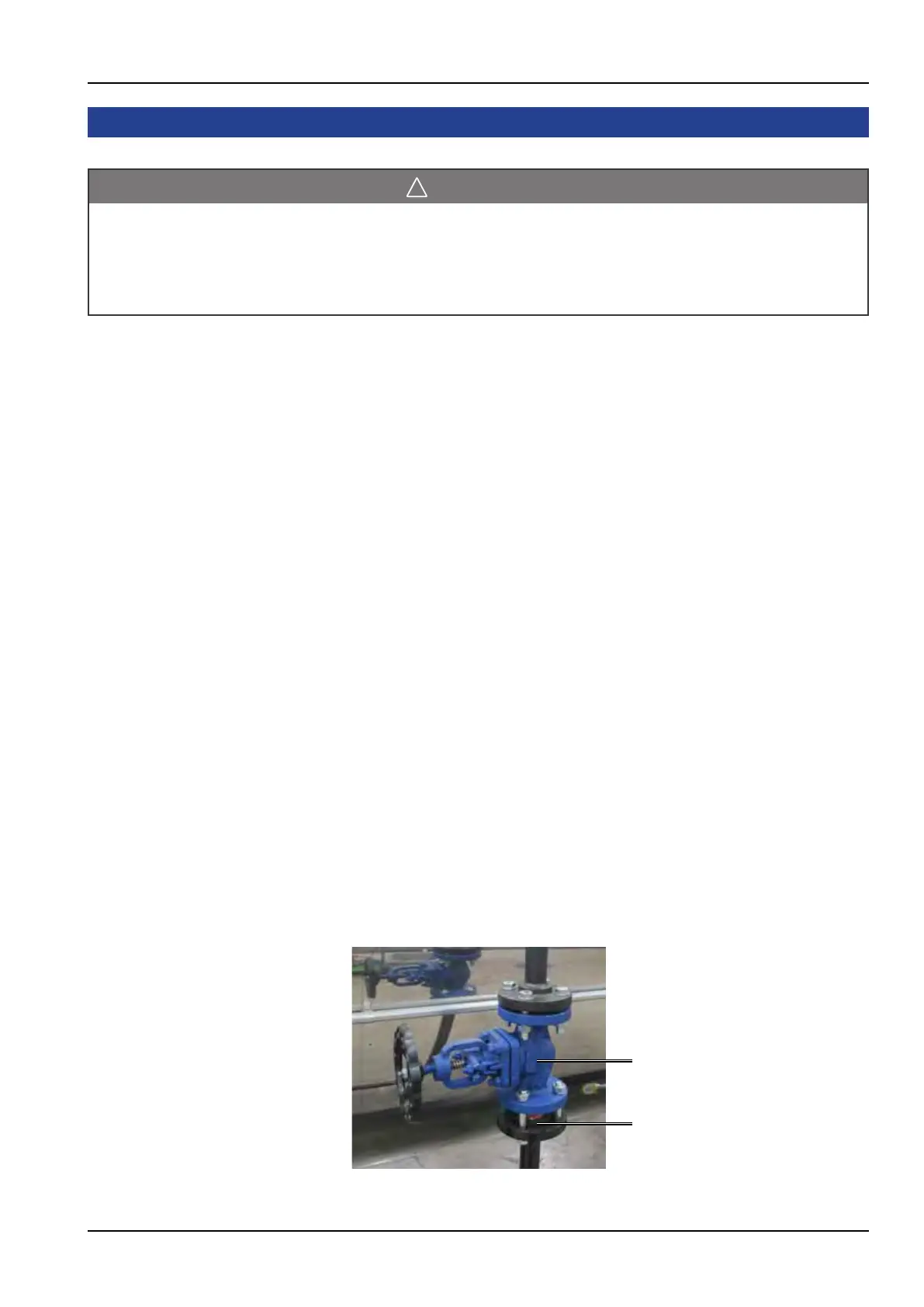

Figure. 8 - Boiler Feedwater Inlet Valve

The quality of the feedwater will affect the life and performance of a steam boiler.

Steamisproducedbyheattransferfromtheheatsourceintothewaterconnedwithintheboiler

cylindrical shell, by the passage of hot gases through the furnace and tubes. It should be noted

that solids entering the boiler with the feedwater can rapidly concentrate at areas of high heat

transfer. Such deposits can restrict heat transfer and consequently raise mean metal temperature,

which can cause corrosion and reduce safety margins possibly to the point of failure.

It is therefore strongly recommended that a reputable water treatment specialist is consulted prior

to putting the boiler into service.

Note: See Appendix A - TI-140-Recommended Water Conditions.

WatercharacteristicsaregenerallyasspeciedinBS24861997“TreatmentofWaterforSteam

Boilers and Water Heaters”, Table 2.

Boilers operating in areas with high residual hardness, high levels of Bicarbonate (temporary)

hardnessandlowcondensatereturnrates,willhavedifcultyinmaintainingTotalandCaustic

Alkalinity(TDS)gures,withinthespeciedlimitswhenbaseexchangesofteningisused.

This will result in a tendency of the boiler water to foam causing unstable water level conditions

possibly leading to priming and carry over. In these instances particular care should be taken to

establish a suitable water treatment programme and blowdown schedule in consultation with your

water treatment specialist.

Cold feedwater contains high levels of dissolved oxygen which is highly corrosive when released

within a steam boiler. Always pre-heat the feedwater to 80 °C - 85 °C to reduce dissolved oxygen

to a minimum and prevent thermal shock. Water treatment chemicals should be used to remove

the remainder of the dissolved oxygen.

Failure to do so will result in premature failure of the boiler tubes which will not be covered by

guarantee.

Feedwater inlet

check valve

Feedwater inlet valve

CAUTION

WATER SOFTENER and CHEMICAL TREATMENT

The chemicals required to operate the water softeners and chemical treatment plants

CAN BE SUPPLIED by Fulton. It is the responsibility of the operator to ensure adequate supplies

of chemical are available at all times (including commissioning). Costly repairs could be required

should the plant operate without chemicals or the wrong dosage of chemicals.

Loading...

Loading...