RB-RBC-IOMM-2015-1

Fulton Ltd

Page 26

OPERATION - 3

Feedwater from a constantly running modulating pump is passed through the economiser before

entering the boiler.

Heat is extracted from the boiler exhaust gases by the economiser which in turn heats the

feedwater to temperatures that can exceed 100 °C.

Backowispreventedbynon-returnvalveinthefeedwaterpipeworkontheinletofthe

economiser.

The economiser is designed to reduce the boiler exhaust temperature to approximately 140 °C,

ifthetemperaturefallssignicantlybelowthisgurecondensationwilloccurwhichcanleadto

corrosion.

Theeconomiseristtedwithinletandoutlettemperaturegaugesforbothfeedwaterandexhaust

gas. These gauges should be used to monitor the condition and performance of the economiser.

Note: Sudden changes in temperature should be reported immediately as they could indicate a blockage of the

economiser water ways, or a malfunction of the modulating feedwater control valve.

Ingenerala10°Cincreaseinfeedwatertemperaturewillgiveanefciencyimprovementof2%.

Because the boiler feedwater modulating control valve and the burner are both proportioned

tothesteamload,theburnerheatinputandcoolingwaterowratetotheeconomiserarein

balancethroughouttheburnerringrange.

A DN20 spill back line with a pneumatically operated piston valve is installed in the feedwater

pipework in the discharge from the pump, the outlet from this valve must be piped back to the

feedwater tank. The purpose of the spill back line is to prevent the constant running feedwater

pumpfromoverheatingshouldthewaterlevelreachthemaximumworkinglevel.Anorice

plateisttedinthespillbacklineinadditiontothepneumaticallyoperatedpistonvalve,witha

manually operated/adjustable globe valve for making small adjustments to the spill back water

owrate.

3.7 INTERNAL ECONOMISER (IF FITTED)

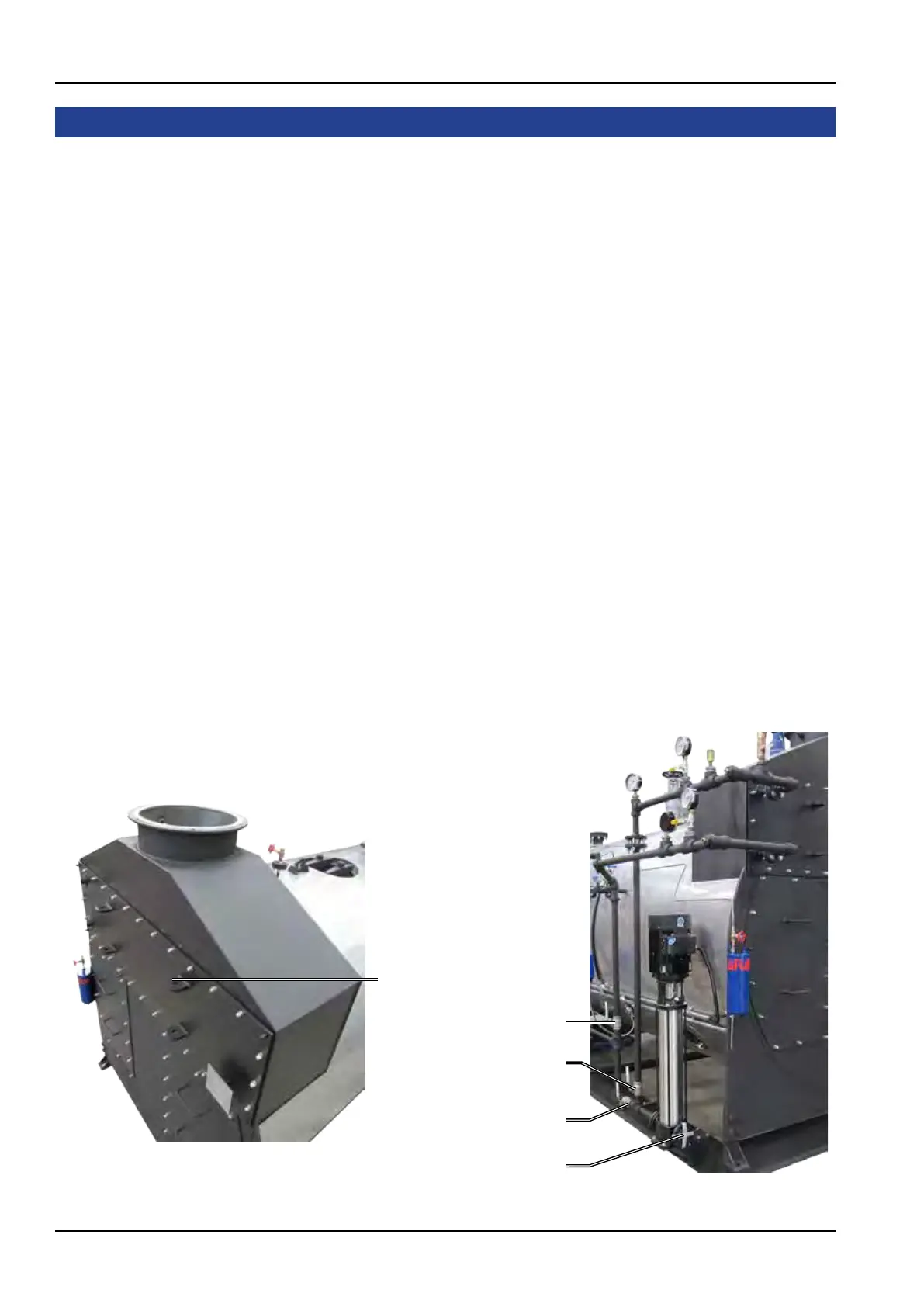

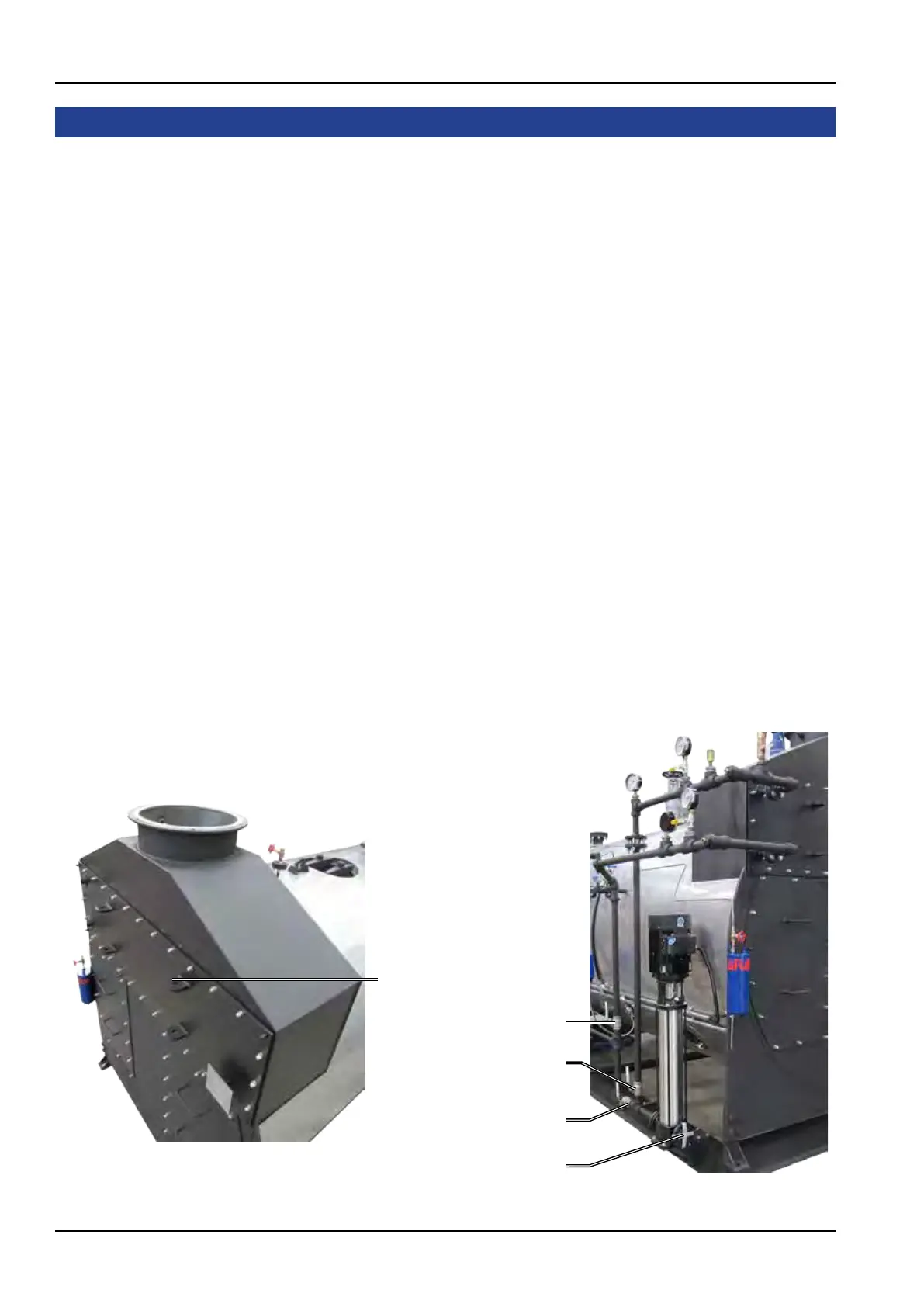

Figure. 17 - Typical Internal Economiser

Internal economisor

Boiler feedwater inlet

Boiler feedwater

economiser bypass valve

Boiler feedwater

economiser inlet valve

Boiler feedwater

economiser outlet valve

Loading...

Loading...