RB-RBC-IOMM-2015-1

Fulton Ltd

Page 64

APPENDIX - A

Automatic TDS Blowdown Systems

Technical Information

Sheet No. 30 Issue 3

Page 1 of 2

The purpose of an Automatic, Total Dissolved Solids (TDS) Control Blowdown System, is to control the TDS level

within the boiler around a set point. It is not a substitute for the main boiler blowdown, which must be used to

control suspended solids, and prevent the build-up of sludge in the bottom of the boiler. The daily testing of boiler

water level controls is a mandatory requirement as dened in the Health & Safety Executive Guidance Note BG01,

Arrangement 3.

The method of operation is to take a sample of the boiler water at pre-set timed intervals, pass the sample over an

electrode which measures water conductivity (which is proportional to TDS for a given water chemistry), and then

compares the result with the control value (normally 2000 ppm), which is set when the unit is commissioned.

If the sample value is higher than the control value, the blowdown solenoid valve opens in a series of pulses until

the measured value corresponds to, or is lower than, the set value. When this is achieved, blowdown nishes until

the next timed sample is taken when the process is repeated. Should the sample value be lower than the set value,

blowdown is deferred until the next timed sample.

For the system to function reliably, the control must be calibrated to a typical water sample that is representative

of the water conditions that are likely to prevail during normal running of the boiler and system. Conductivity and

as a consequence TDS, can vary signicantly with water chemistry. Changes in condensate return rates, alkalinity,

chemical dosage, and suspended solids can all affect the performance of an Automatic TDS Blowdown System.

Condensate return rates that vary greatly on a day to day basis can severely disrupt the reliability of the

conductivity measurement.

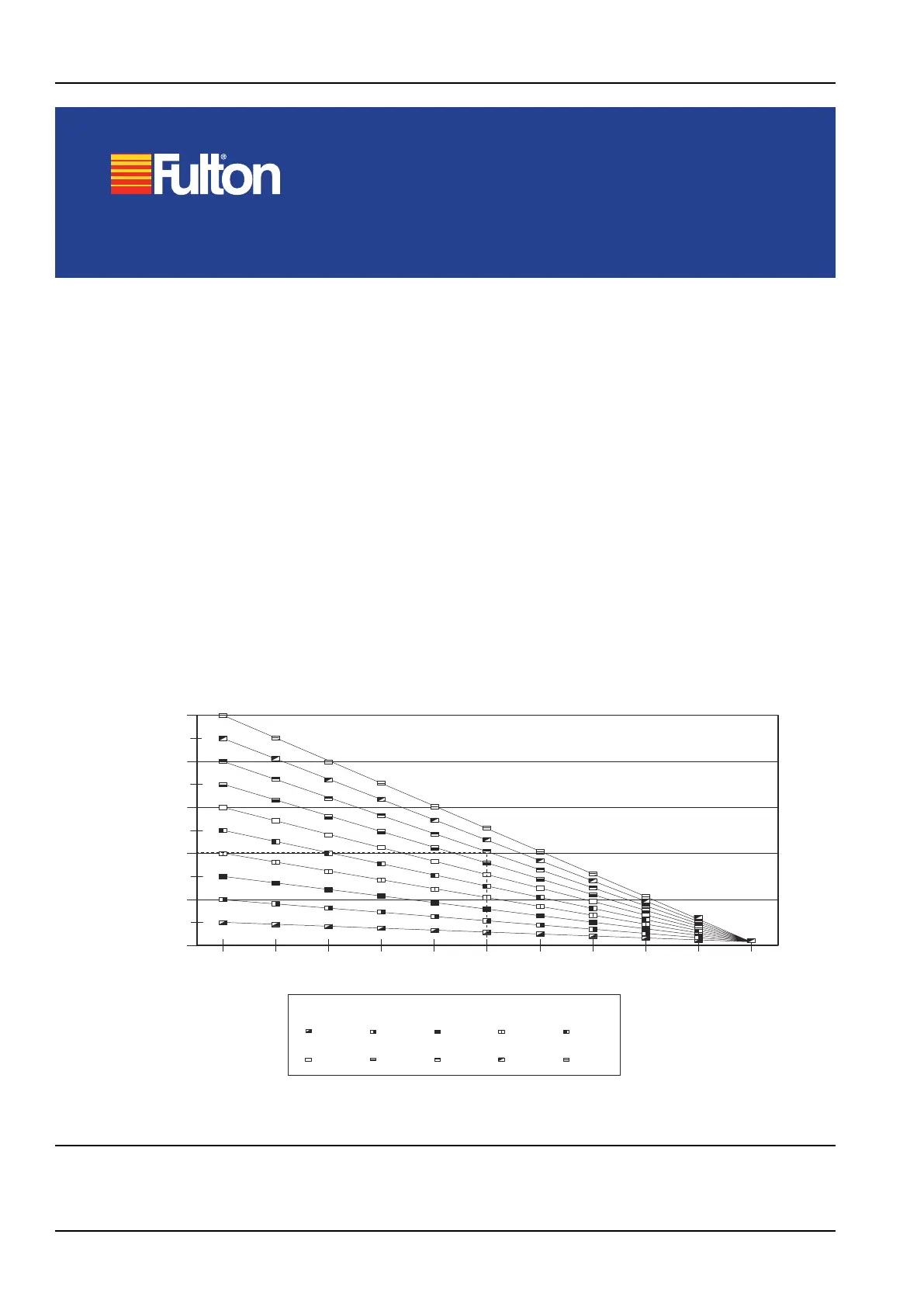

500

400

300

200

100

0

0 10 20 30 40 50 60 70 80 90 100

Feed water TDS at varying

condensate return rates

Condensate return(%)

Raw water TDS (ppm)

50

300

100

350

150

400

200

450

250

500

Feed water TDS (ppm)

e.g. A boiler with a 50% condensate return and a raw water TDS of 400 will have a boiler feed water TDS of 200 ppm.

Figure. 1 - TDS Graph 1

Loading...

Loading...