RB-RBC-IOMM-2015-1

Fulton Ltd

Page 61

APPENDIX - A

Boiler Water Sample Cooler

Installation & Operation

Technical Information

Sheet No. 122 Issue 4

Page 1 of 2

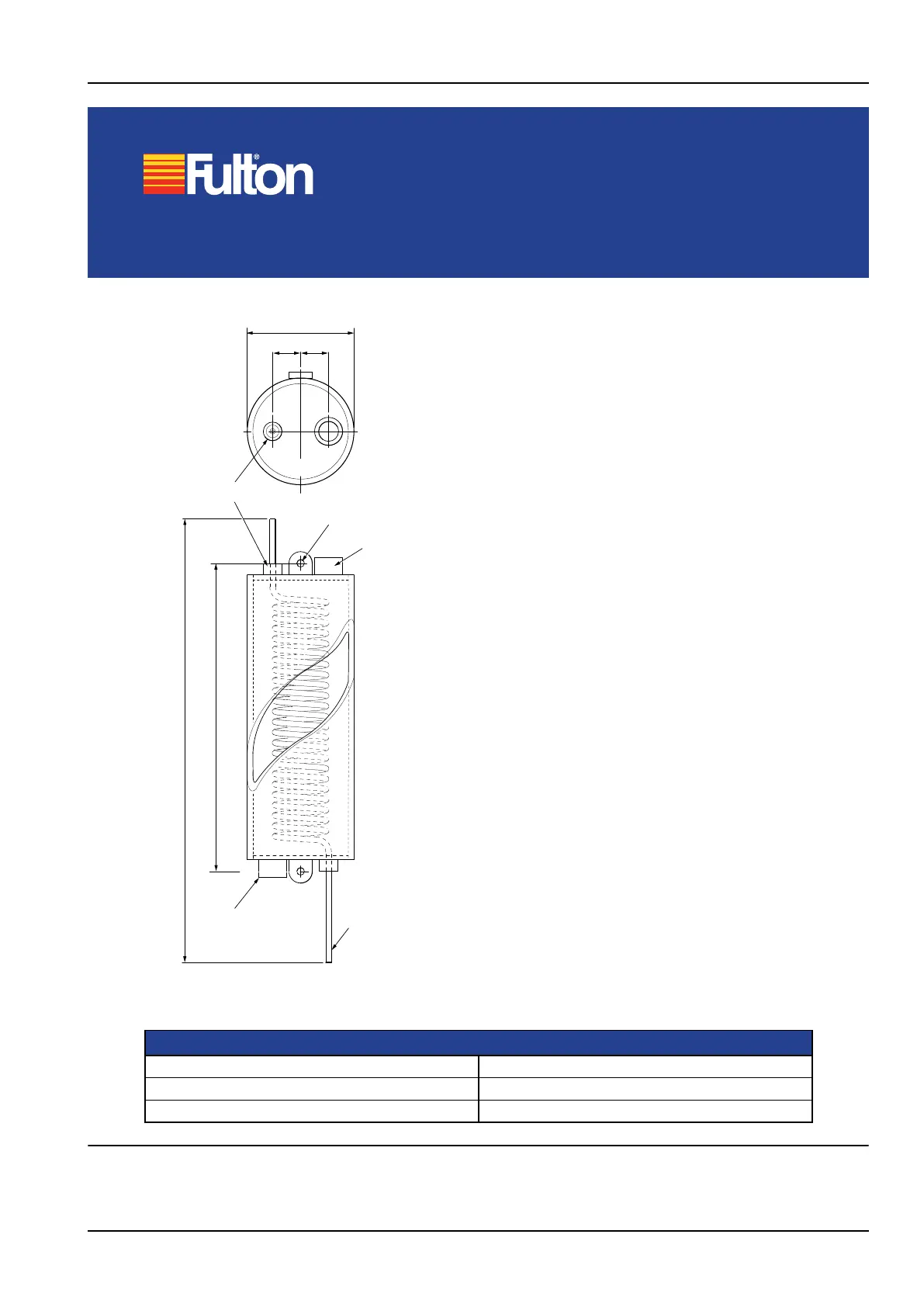

CONNECTIONS

Cooling Water Inlet

DN15 (1/2in.BSP), Valve Fitted

Cooling Water Outlet

DN15 (1/2in.BSP)

Sample Water Inlet

DN8 (1/4in.BSP) Valve Fitted to 6 mm O/D tube

30

475 mm min.

Sample Water Inlet,

(DN8, 1/4in. BSP)

330 mm

30

Sample Water Outlet Tube

(6 mm stainless steel)

100 mm diameter

Securing Hole

(8 mm diameter)

Cooling Water Outlet,

(DN15, 1/2in. BSP)

Cooling Water Inlet,

(DN15, 1/2in. BSP)

The sample cooler is supplied complete with:

• Cooling water inlet valve

• Sample water inlet valve

WHY SAMPLE WATER?

In order to ensure the safe, efcient and economical running

of boiler plant, it is imperative the boiler water is sampled for

analysis at frequent and regular intervals.

The Fulton water sample cooler has been designed and

manufactured to facilitate the safe monitoring of the boiler

water.

OPERATION

Always assume the boiler sample water is capable of

scalding until the sample is taken and has cooled down.

1. Normal Boiler Operation (sample not required)

Ensure the valve at the boiler, feeding the sample cooler

is closed.

Ensure the boiler water sample valve and the cooling

water inlet valves are closed.

2. Taking a Sample

When a sample is ready to be taken, open the cooling

water inlet valve and check the water is owing through

the cooler to drain.

Provide a suitable receptacle to receive the sample.

Open the boiler water sample valve adjacent to the boiler

and slowly open the boiler water sample valve located

on the sample cooler, allow the sample water to run for

approximately 30 seconds to remove the standing water

from the sample cooler feed line.

Take a sample of the boiler water.

3. When the sample has been taken, close the boiler water

sample valve and the cooling water inlet valve.

Close the boiler valve feeding the sample cooler.

Loading...

Loading...