RB-RBC-IOMM-2015-1

Fulton Ltd

Page 12

INSTALLATION - 2

2.10.2 OIL SUPPLY

Oil-redboilersaresuppliedwitha

matched, automatic high/low oil burner

suitable for use with 35 SRNI fuel oil.

A single-pipe system can be used where

thesuctionisfullyooded,however,for

systemswhere‘lift’isrequired,itwillbe

necessary to install a two-pipe system.

For more details consult the burner

manufacturer’sinstructionmanual.

The following points should be observed:

a) Alwaysinstallanoillter.

b) Useexiblepipeworkforthenaloil

connections to the oil pump.

c) Fit isolating valves to the pump.

d) Ensure that the supply pipework is

sized to cause a minimum pressure

drop.

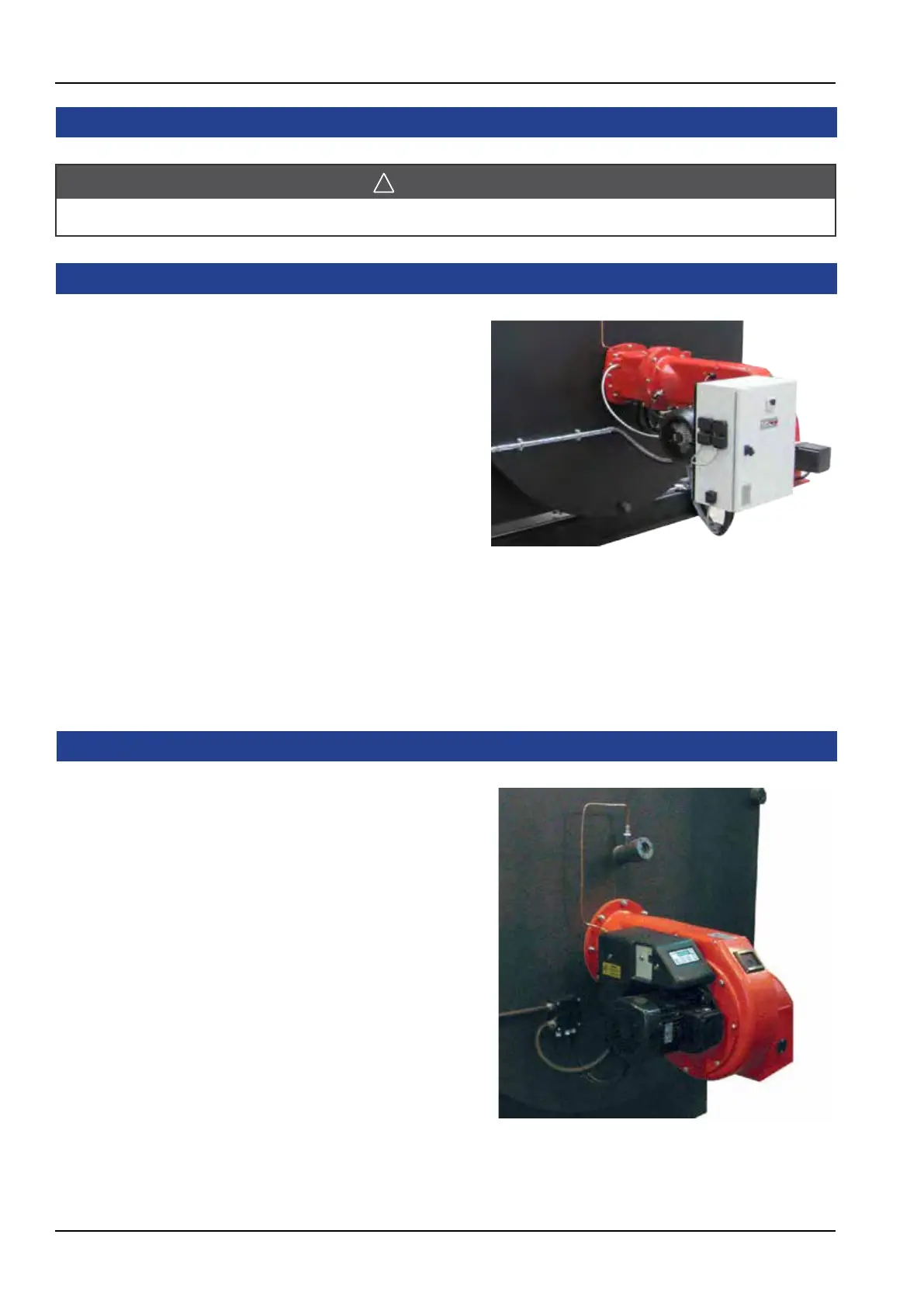

Figure. 10 - Oil Burner Installation

Note: Installation will change with the type of

burner tted.

2.10 FUEL SUPPLY

WARNING

Do not change the boiler fuel without consulting the boiler manufacturer.

2.10.1 GAS SUPPLY

The gas/pressure requirement varies

according to the burner size and the gas

train selected.

Verify that the type and pressure of the

gas available on the site is suitable for the

burnertted.

If the site gas pressure is too low, it will be

necessarytotagasboostersystem.

Consult Fulton Ltd if in doubt.

To minimise pressure drops, eliminate

all unnecessary bends and elbows in the

pipework between the gas meter and the

inlet to the gas train.

Ensure that a gas cock of the correct size

is installed as close as possible to the gas

train.

All gas pipework must be installed by

‘CompetentPersons’inaccordancewith

the gas regulations.

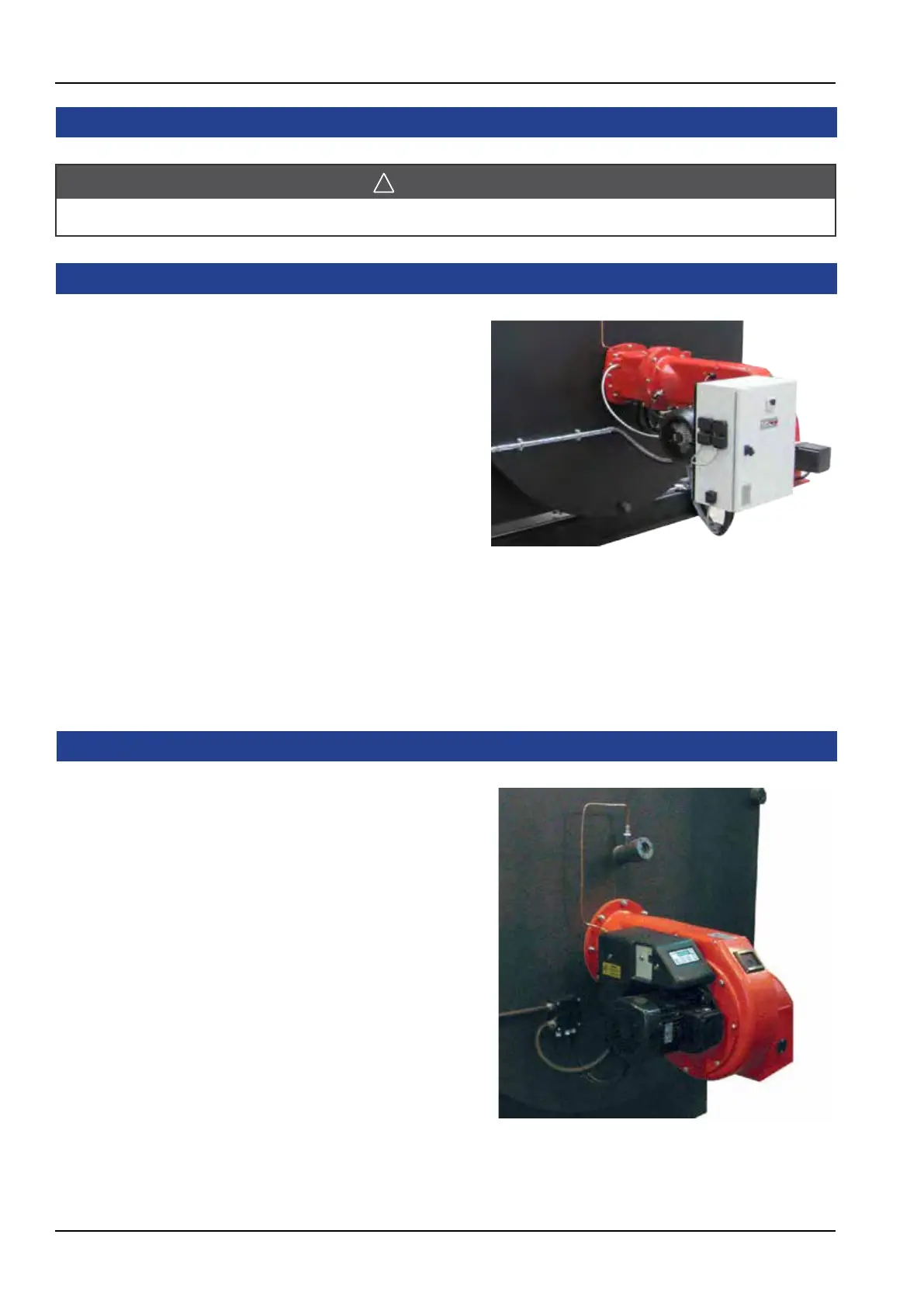

Figure. 9 - Gas Burner Installation

Note: Installation will change with the type of

burner tted.

Loading...

Loading...