1-6 Series 90-30 PLC Installation and Hardware Manual

–

August 2002 GFK-0356Q

1

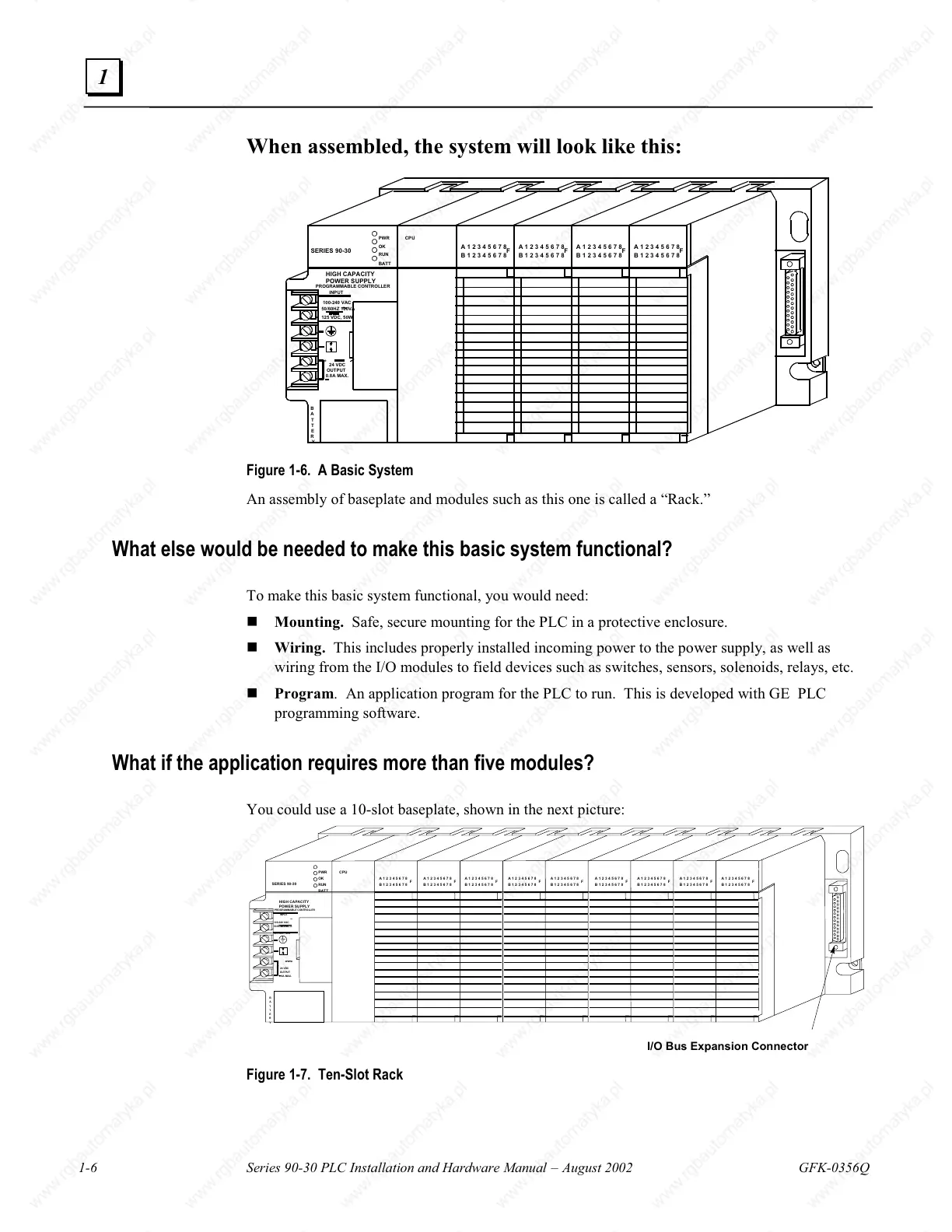

When assembled, the system will look like this:

0.8A MAX.

OUTPUT

HIGH CAPACITY

125 VDC, 50W

+

100-240 VAC

50/60HZ 100VA

24 VDC

INPUT

POWER SUPPLY

PROGRAMMABLE CONTROLLER

SERIES 90-30

~

PWR

OK

RUN

BATT

B

A

T

T

E

R

Y

A 1 2 3 4 5 6 7 8

F

B 1 2 3 4 5 6 7 8

A 1 2 3 4 5 6 7 8

F

B 1 2 3 4 5 6 7 8

A 1 2 3 4 5 6 7 8

F

B 1 2 3 4 5 6 7 8

A 1 2 3 4 5 6 7 8

F

B 1 2 3 4 5 6 7 8

CPU

Figure 1-6. A Basic System

An assembly of baseplate and modules such as this one is called a “Rack.”

What else would be needed to make this basic system functional?

To make this basic system functional, you would need:

Mounting. Safe, secure mounting for the PLC in a protective enclosure.

Wiring. This includes properly installed incoming power to the power supply, as well as

wiring from the I/O modules to field devices such as switches, sensors, solenoids, relays, etc.

Program. An application program for the PLC to run. This is developed with GE PLC

programming software.

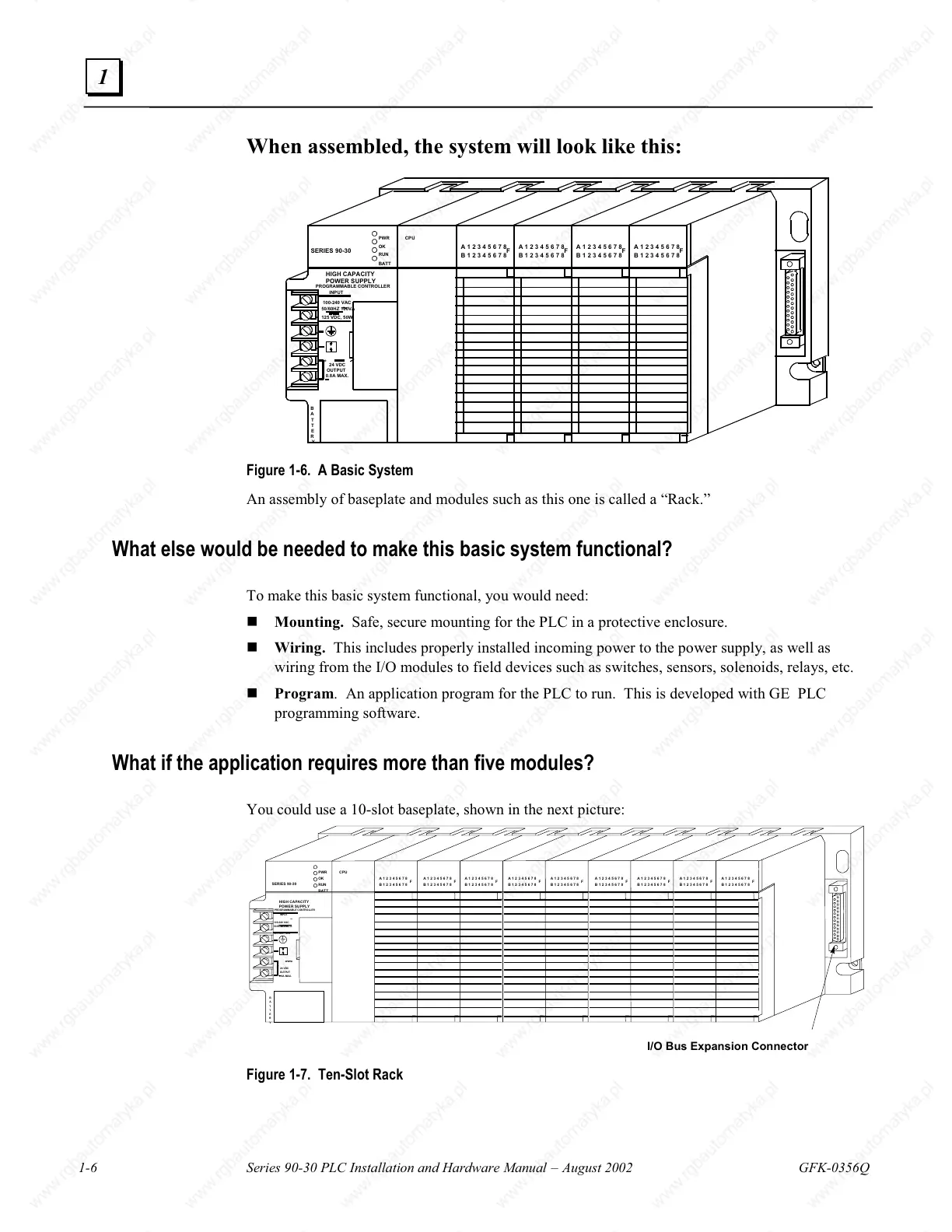

What if the application requires more than five modules?

You could use a 10-slot baseplate, shown in the next picture:

HIGH CAPACITY

125 V DC, 50W

+

100- 240 VAC

50/60H Z 100V A

24 V DC

OUTPUT

0.8A MAX.

INPUT

POWER SUPPLY

PROGRAMMABLE CONTROLLER

SERIES 90-30

~

B

A

T

T

E

R

Y

PWR

OK

RUN

BATT

A 1 2 3 4 5 6 7 8

F

B 1 2 3 4 5 6 7 8

A 1 2 3 4 5 6 7 8

F

B 1 2 3 4 5 6 7 8

A 1 2 3 4 5 6 7 8

F

B 1 2 3 4 5 6 7 8

A 1 2 3 4 5 6 7 8

F

B 1 2 3 4 5 6 7 8

A 1 2 3 4 5 6 7 8

F

B 1 2 3 4 5 6 7 8

A 1 2 3 4 5 6 7 8

F

B 1 2 3 4 5 6 7 8

A 1 2 3 4 5 6 7 8

F

B 1 2 3 4 5 6 7 8

A 1 2 3 4 5 6 7 8

F

B 1 2 3 4 5 6 7 8

A 1 2 3 4 5 6 7 8

F

B 1 2 3 4 5 6 7 8

CPU

I/O Bus Expansion Connector

Figure 1-7. Ten-Slot Rack

Loading...

Loading...