Chapter 4. Error Codes and Troubleshooting

76 PanaFlow™ LC User’s Manual

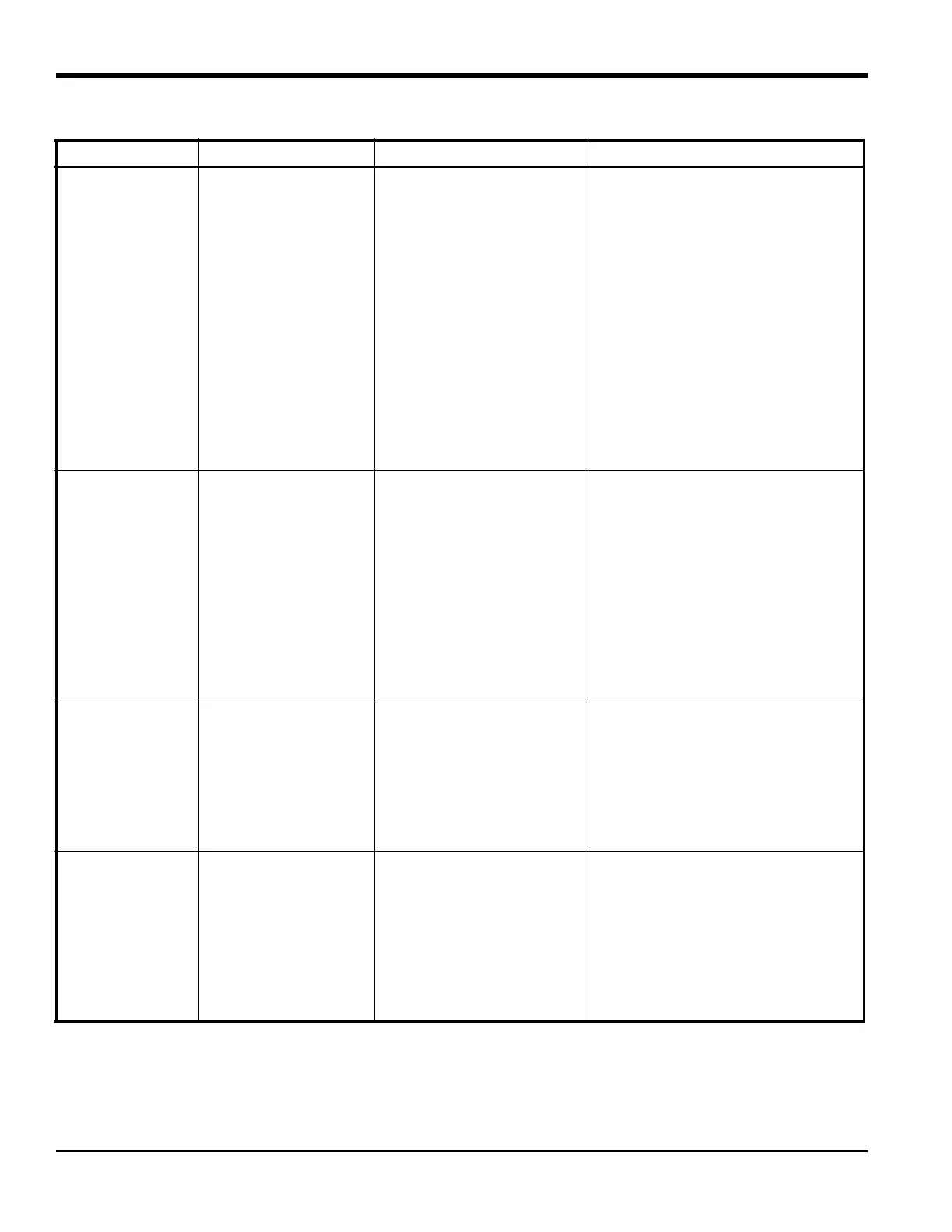

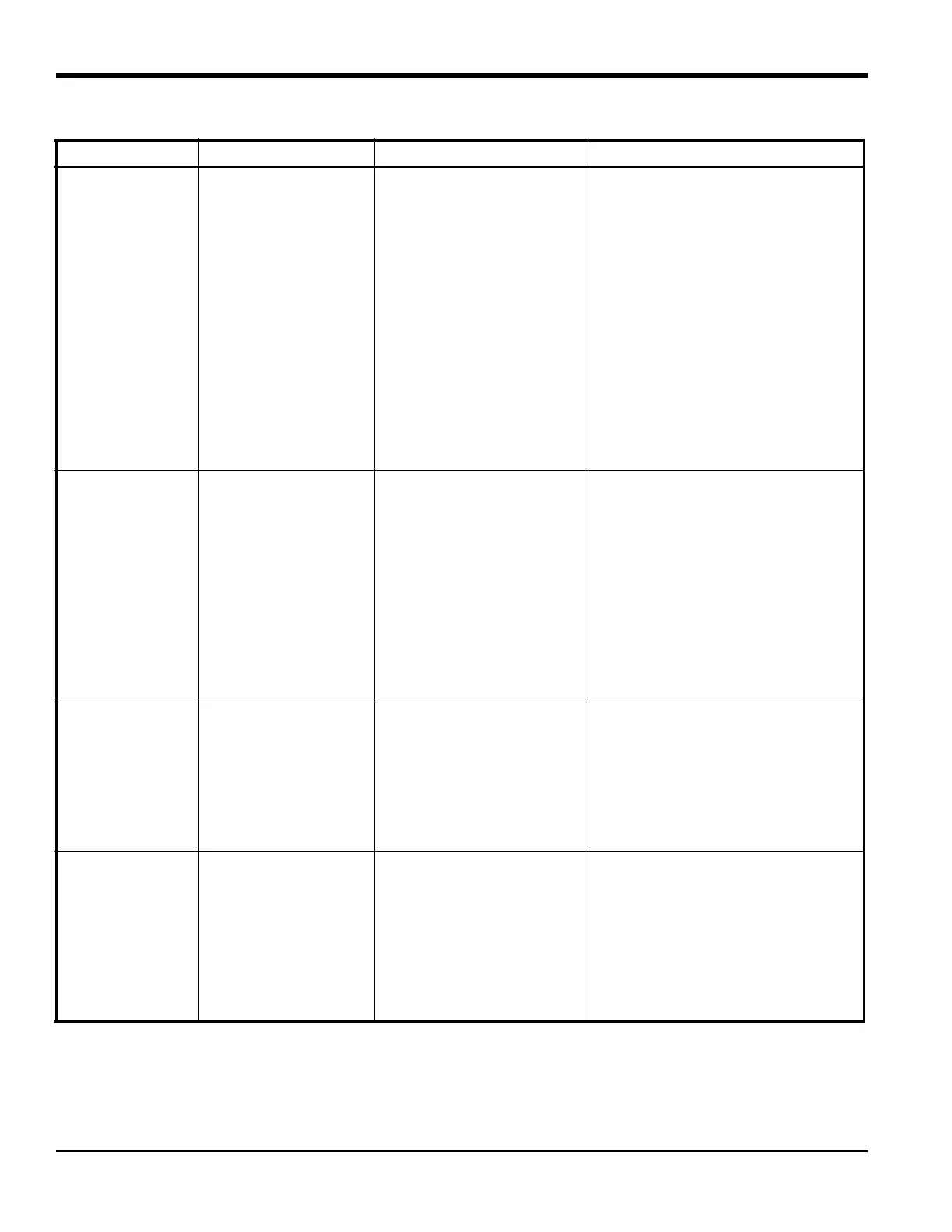

Table 21: Flow Error description and Recommended Actions

Error Code Problem Cause Recommended Action

E1: SNR The Signal to Noise

ratio is low

The acoustic signal from

the process is very weak.

This could be due to

bubbles, other fluid

conditions, an empty pipe,

broken cables,

transducers, couplant or

buffers

Check if the Active Tw

measurement on upstream and

downstream transducers is valid. If

Active Tw measurement is valid

then this error is an indication of

the problem with the process

conditions.

If Active Tw measurement is not

valid then check the value entered

in SNR Min Error Limits option

(Refer Programming Chapter). Also,

refer to “Fluid and Pipe Problems”

and “Transducer Problems”

sections to correct for any issues

E2: Soundspeed The measured sound

speed exceeds

programmed limits

The error may be caused

by incorrect

programming, poor flow

conditions or poor

transducer orientation. It

may also occur if signal

quality is poor

Compare the measured sound

speed to programmed nominal

values for the process fluid and

correct any programming errors.

Refer to “Fluid and Pipe Problems”

and “Transducer Problems”

sections to correct for any issues.

In case you are unable to clear the

errors, gather the required

diagnostics before contacting

BHGE

E3: Velocity

Range

The measured

velocity exceeds

programmed limits

This error may be caused

by incorrect

programming, poor flow

conditions and/or

excessive turbulence

Make sure the actual flow rate is

within the programmed Error

limits (Refer Programming

Chapter). Refer to “Fluid and Pipe

Problems” and “Transducer

Problems” sections to correct any

issues

E4: Signal

Quality

The signal quality is

lower than the

programmed limits

This means the signal

shape, upstream to

downstream reciprocity,

or signal correlation value

has fallen below the

correlation peak limit. The

cause is usually the same

as E6 or E5

Make sure the Signal Quality is

greater than the programmed Error

limits (Refer Programming

Chapter). Refer to “Fluid and Pipe

Problems” and “Transducer

Problems” sections to correct any

issues. Gather required diagnostics

data before contacting BHGE

Loading...

Loading...