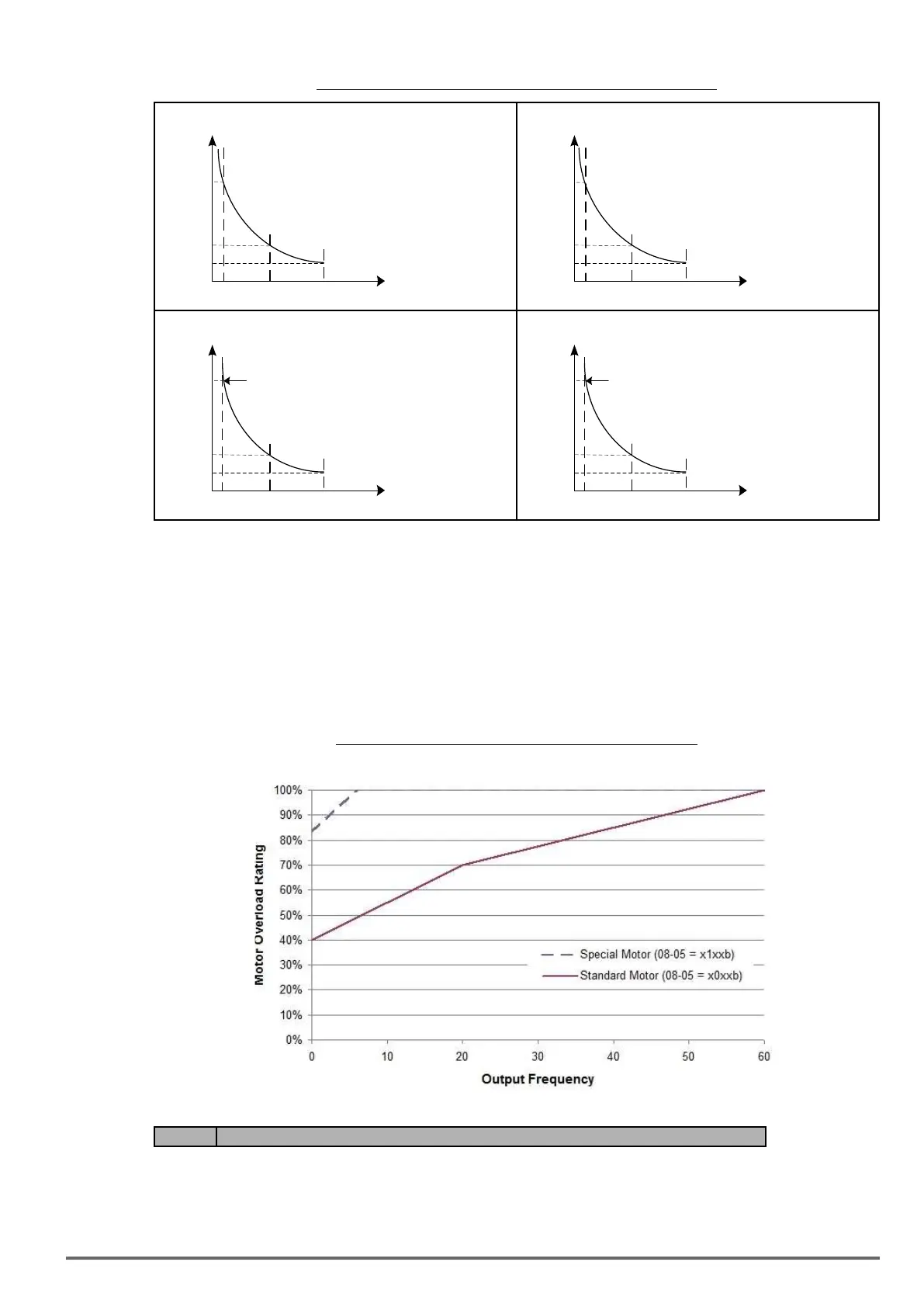

Figure4.4.71Motoroverloadprotectioncurve(example:standardmotor)

Low Speed

Hot Start

100% 150% 200%

Motor Load Current (%)

(02-01 = 100%)

Overload Protect Time (min)

1.5

2.9

7.9

Low Speed

Cold Start

100% 150% 200%

Motor Load Current (%)

(02-01 = 100%)

Overload Protect Time (min)

2.4

4.5

12.4

(60Hz)

Hot Start

106% 150% 200%

Motor Load Current (%)

(02-01 = 100%)

Overload Protect Time (min)

1.7

3.9

28.8

start activacted point

(60Hz)

Cold Start

106% 150% 200%

Motor Load Current (%)

(02-01 = 100%)

Overload Protect Time (min)

2.7

6.1

45.2

start activacted point

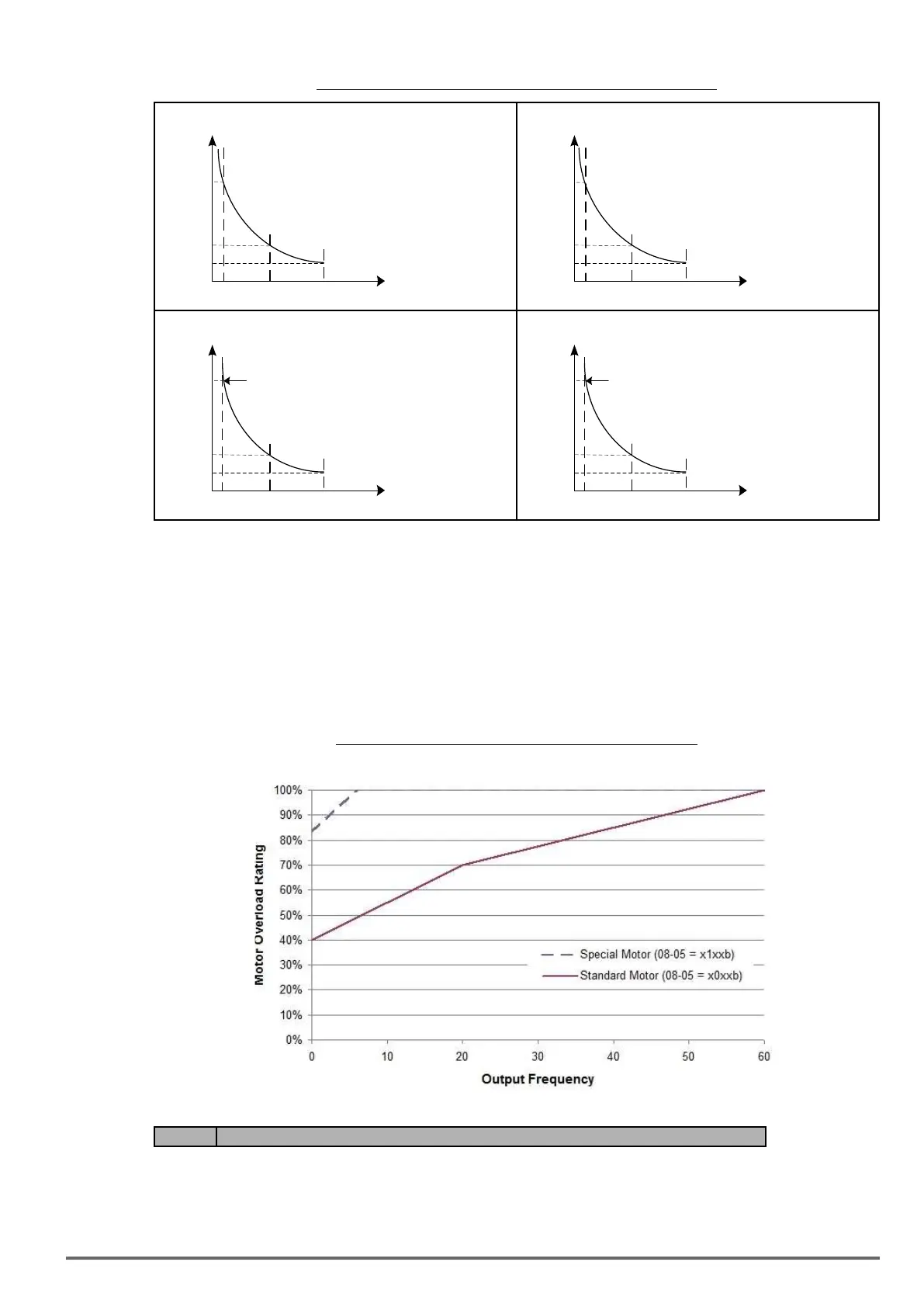

When using force cooled motors (Special inverter motor), thermal characteristics are independent of the motor

speed, set 08-05 = x1xxb.

When 08-05 = x1xxb, overload protection function is based on motor rated current for output frequencies be-

tween 6 and 60Hz. If the output frequency is lower than 1Hz, the overload protection function uses 83% of the

motor rated current to determine an overload condition.

When 08-05 = x0xxb, overload protection function is based on 70% of the motor rated current for an output

frequency of 20Hz. If the output frequency is lower than 1Hz, the overload protection function uses 40% of the

motor rated current to determine an overload condition.

Motor overload rating at different output frequencies is shown at Figure 4.4.72.

Figure4.4.72Motoroverloadratingatdifferentoutputfrequencies

Code Parameter Name / Range

08-06 Start-up mode of overload protection operation (OL1)

0: Stop output after overload protection

1: Continuous operation after overload protection.

08-06=0: When the inverter detects a motor overload the inverter output is turned off and the OL1 fault mes-

VDI100 • Instruction manual 205

Loading...

Loading...