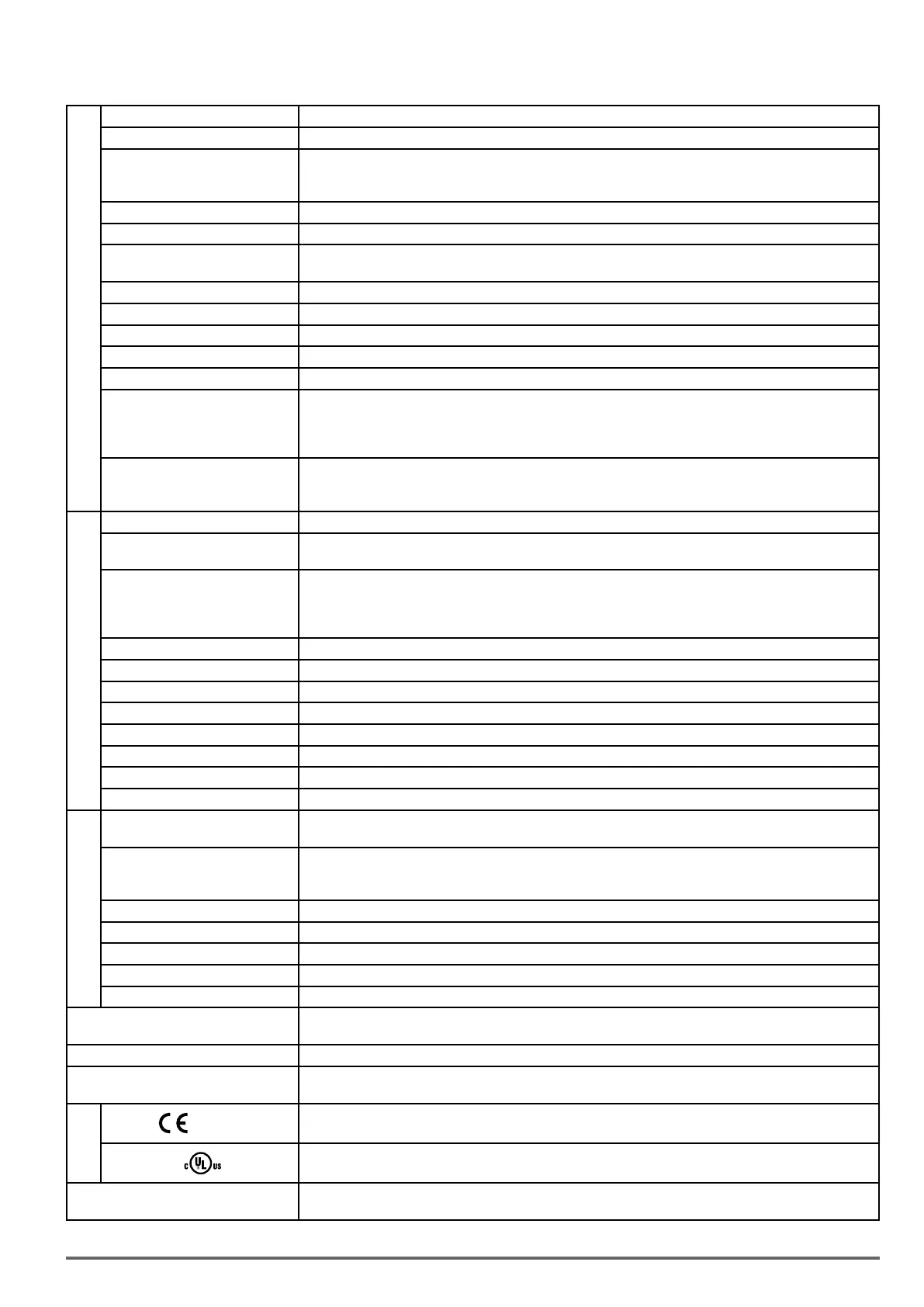

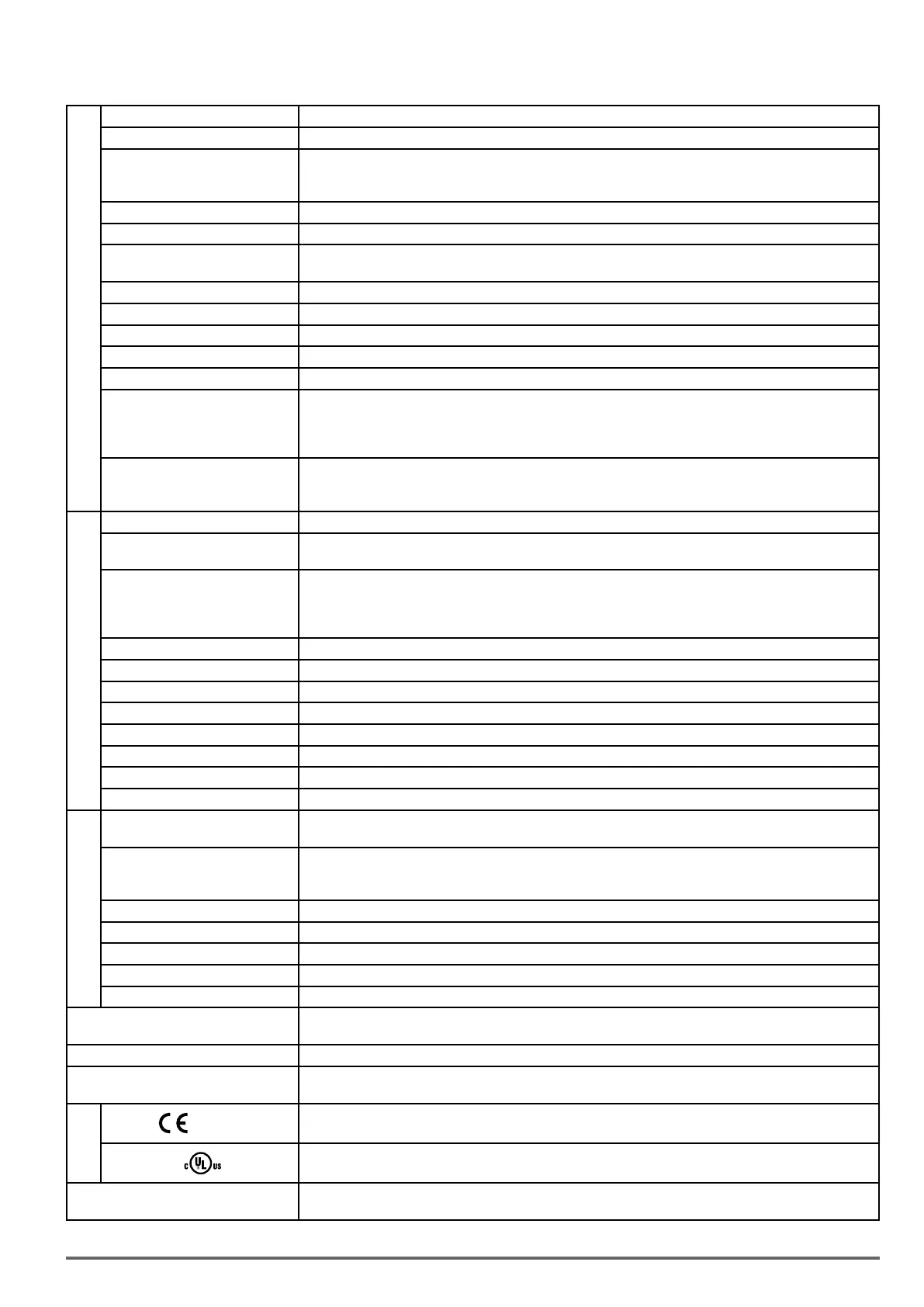

3.18.2. General Specications

Control Characteristics

Motor type Asynchronous Motor, Surface Permanent Magnet Motor, Interior Permanent Magnet Motor

Control Modes V/f, V/f+Encoder, SLV (vector control open loop), SV (vector control closed loop), PMSLV, PMSV

Speed control accuracy

±1% (SLV, overload 200% and control range 1 : 30 (60....2Hz ; 50...1.6Hz)),

±1% (SLV, overload 150% and control range 1 : 50 (60....1.2Hz ; 50...1Hz)),

±1.5% (V/f open-loop, overload 150% and control range 1 : 40 / 60....1.5Hz ; 50...1.25Hz), ±0.1% (SV)

Output Frequency 0.1Hz~599Hz

Output Frequency Resolution 0.01Hz

Overload Tolerance

Heavy Duty Mode (HD.): 150% rated current for 60sec, 200% rated current for 2 sec. (Factory default)

Normal Duty Mode (ND.): 120% rated current for 60sec

Frequency Setting Signal 0 to +10V, -10V to +10V, 4 to 20mA or pulse train input

Acceleration / Deceleration Time 0.0 ~ 6000.0 sec (separate acceleration and deceleration time set)

Voltage / Frequency Characteristics 15 fixed + one customized V/f pattern

Braking Unit Built-in braking transistor on 3ph 400V Class 0.75-30kW HD and on (1ph)/3ph 230V Class 0.75-18.5kW HD

Display LED keypad with 5-digits 7-segment display (LCD keypad option)

Main Control Functions

Auto-tuning, Zero Servo, Torque Control, Position Control, Droop, Soft-PWM, Over-Voltage Protection, Dynamic

Braking, Speed Search, Frequency Traversing, Momentary Power Loss Restart, PID Control, Automatic Torque

Compensation, Slip Compensation, RS-485 Communication, Close Loop Control with encoder, Simple PLC Func-

tion, 2 Analog Output, Torque-Off function, Application Presets

Other Functions

Records of Power ON and Operation Time, 30 Fault History Records and Latest Fault State Record, Energy-Saving

Function, Phase Loss Protection, DC Braking, Mechanical Brake Control, Dwell, S Curve Acceleration and Decelera-

tion, Pulse input / output, Display of Engineering Unit, NPN / PNP Selection

Protection Functions

Stall Prevention During Acceleration, Deceleration and continuous run

Over Current (OC) and Output

Short-Circuit (SC) Protection

When the current exceeds 200% of the inverter rated current

Inverter Overload Protection (OL2)

Inverter stops when the output is higher than below conditions.

Heavy Duty Mode (HD.): 150% rated current for 60sec, 200% rated current for 2 sec. (Factory default), Carrier

frequency is from 2kHz to 8kHz

Normal Duty Mode (ND.): 120% rated current for 60sec, Carrier frequency is 2kHz

Motor Overload Protection (OL1) Electrical overload protection curve

Over Voltage Protection (OV) OV threshold = 410Vdc (230V class), 820Vdc (400V class)

Under Voltage (UV) UV threshold = 190Vdc (230V class), 380Vdc (400V class)

Momentary Power Loss Restart When Power loss exceeds 15ms. This function can be set up to 2 sec

Overheat Protection (OH) Thermistor sensor on heatsink

Ground Fault Protection (GF) Protection by current detection circuit

Charge Indicator When main circuit DC voltage ≥ 50V, the CHARGE LED is on

Output Phase Loss Protection (OPL) If the OPL function acts, the motor stops rotation automatically

Environment

Specification

Protection degree

Sizes 1 to 5: IP20 / NEMA 1, with standard removable anti dust cover

Sizes 6-7: IP00; available optional NEMA 1 kit (cover and conduit box)

Operating Temperature

-10~+50°C (Sizes 1 to 5 without anti dust cover; sizes 6 -7)

-10~+40°C (Sizes 1 to 5 with anti dust cover; sizes 6 -7 with NEMA 1 kit)

Up to +60°C with derating.

Storage Temperature -20 ~ +70°C

Humidity 95% RH or less (no condensation)

Altitude Altitude of 1000 meters or lower

Vibration 1.0G, in compliance with IEC 60068-2-6

Pollution Degree Meet IEC 60721-3-3 Class 3C2

Communication Function

Built-in: RS-485 with Modbus RTU / ASCII (standard RJ45 connection)

Optional: Profibus/CANopen/DeviceNet/TCP-IP

DC choke Built-in on 3ph 400V Class 75-160kW HD

EMC filter

Add-on module on –F version 3ph 400V Class 0.75-45kW HD

In compliance with EN61800-3:2012 standard

Certification

RoHS

In compliance with EN61800-3 (EMC) and EN61800-5-1(LVD)

Conformity to RoHS directive

UL508C

Encoder expansion card (optional)

Asynchronous Motor: Digital incremental Line driver and Open collector

PM motor: Digital incremental Line driver, Resolver, SinCos

VDI100 • Instruction manual 37

Loading...

Loading...