PART 4

ENGINE/DC CONTROL

Page 100

Section 4.3

Operational Analysis

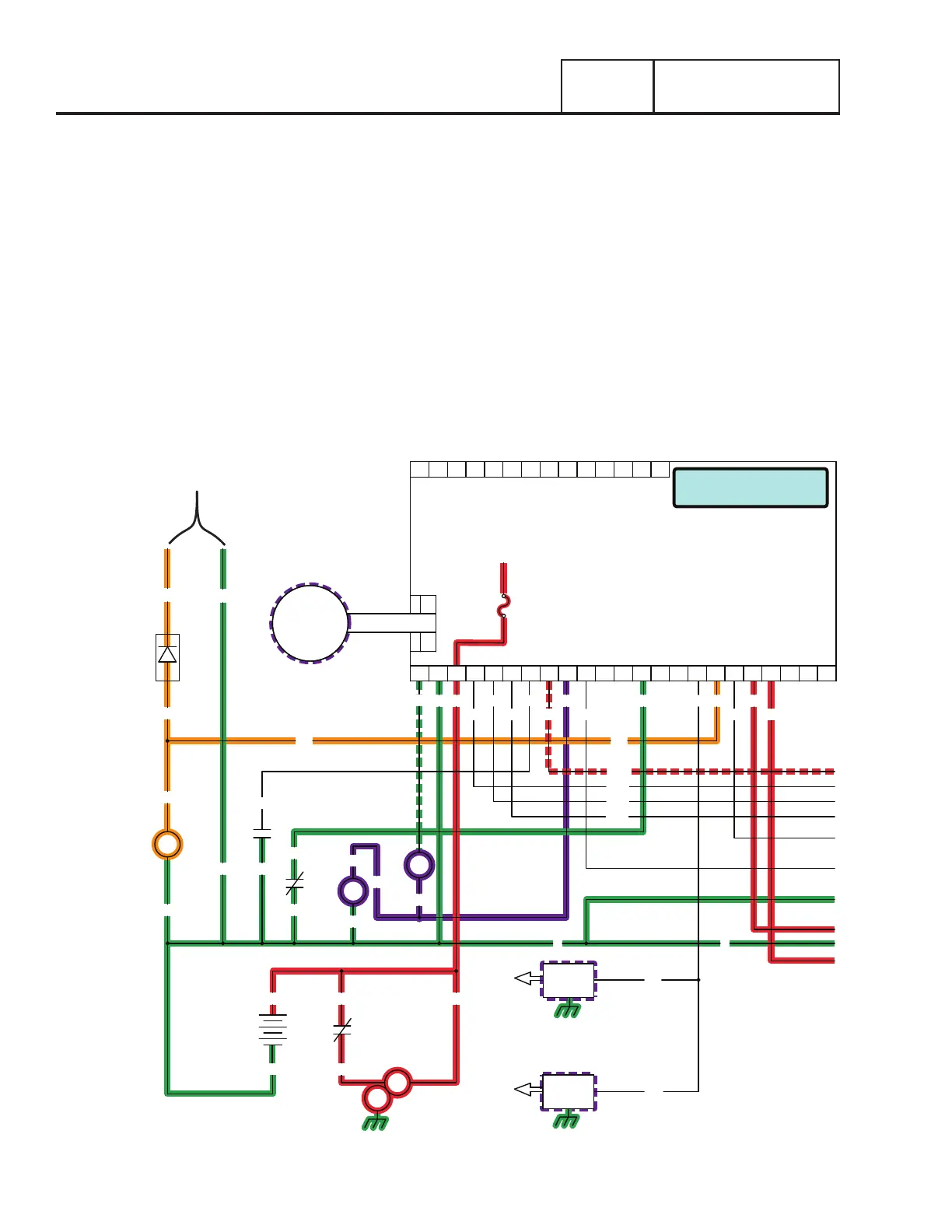

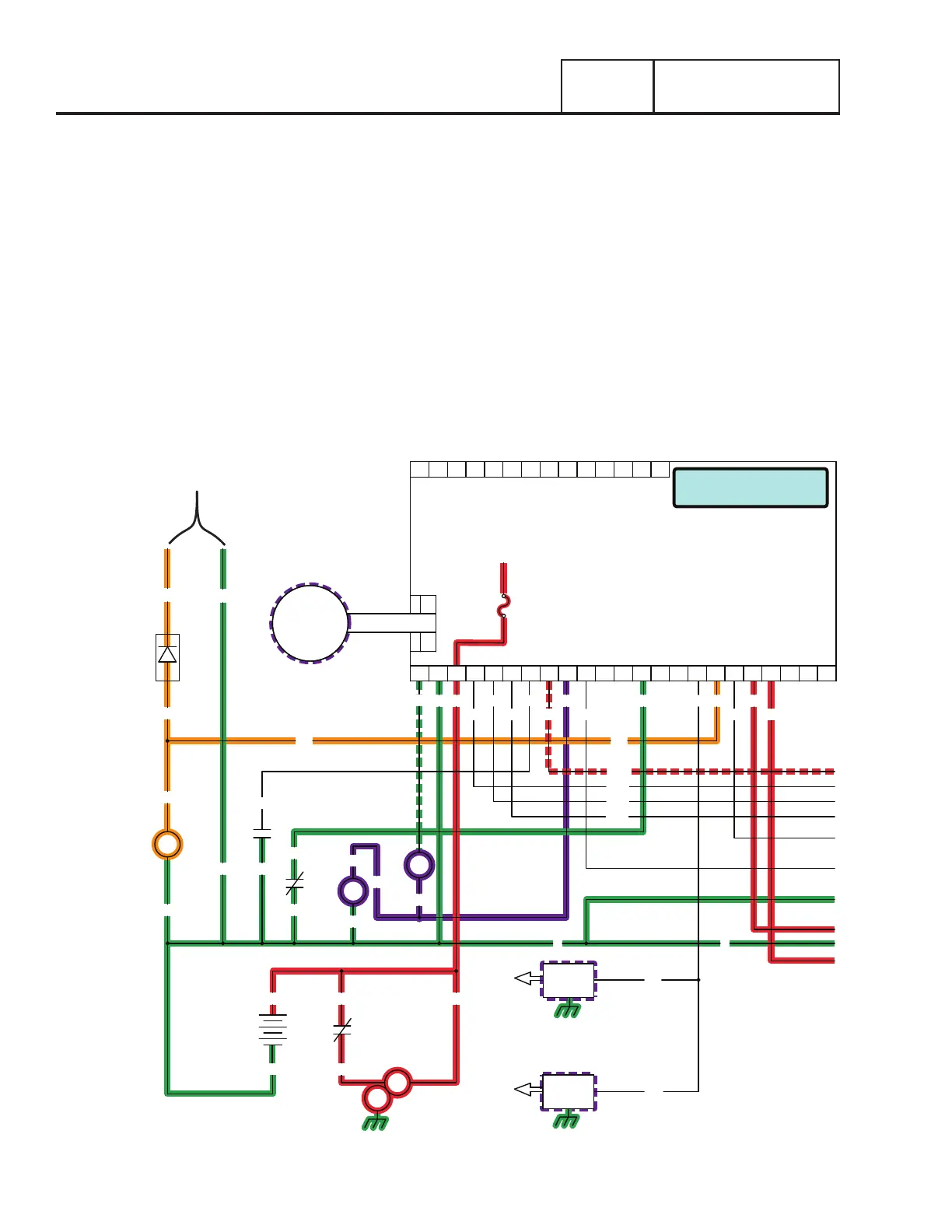

UTILITY VOLTAGE FAILURE AND ENGINE CRANKING

•After the controller’s 10-second timer has timed out, if Utility voltage is still below 65% of nominal, the controllers logic will

energize the internal crank relay followed by the internal run relay.

•When the internal crank relay energizes 12 VDC is delivered to the starter contactor relay (SCR) via Wire 56. When the SCR

energizes its contacts close and battery voltage is delivered to a starter contactor (SC). When the SC energizes its contacts close

and battery voltage is delivered to the starter motor (SM); the engine is now cranking.

•With the engine cranking a speed reference signal is generated by the magnetos and is delivered to the controller through Wire

18. If a valid signal is received, the controller will energize the internal run relay and deliver 12VDC on Wire 14. The fuel solenoid

energizes (opens) and fuel is available to the engine. The choke solenoid (CS) begins to operate and the controller grounds Wire

90, energizing the choke solenoid cyclically curing cranking, and continuously while running.

•During Cranking 3-5VDC is supplied to the rotor for field flash via a field boost diode connected in parallel with Wire 56.

•With ignition and fuel flow available the engine will start.

Crank Atempt # 1

F1

TO PCB

18

SP2

IM2

0

85

HTO

18

0

12V

BATTERY

SCR

IM1

SP1

56

0

820

817

818

819

ACTUATOR

J3

GOVERNOR

14

1886

0

FS

0

CS

J5

PRINTED CIRCUIT BOARD

CONTROLLER

J4

18171615141312109 1186 721 43 5 2322212019

90

0 13

817

818

819

85

820

14

14

14

210

LOP

0

86

56 194

209 23

141312109 1186 721 43 5

DIODE

FIELD BOOST

0

56

56

56

4

16

13

SCR

SM

SC

13 13

0

0

A

B

TO ROTOR

Figure 97.

Loading...

Loading...