PART 1

GENERAL INFORMATION

Page 14

Section 1.2

Installation Basics

vary considerably, depending on ambient temperatures. In

cold weather, supply pressures may drop to “zero”. In warm

weather, extremely high gas pressures may be encountered.

A primary regulator is required to maintain correct gas supply

pressures.

Required fuel pressure for natural gas is 5 inches to 7 inches

water column (0.18 to 0.25 psi); and for liquid propane, 10

inches to 12 inches of water column (0.36 to 0.43 psi).

Note: To maintain proper fuel pressure a primary regulator

is required.

LP and Natural Gas are both highly explosive. Gaseous

fuel lines must be properly purged and tested for

leaks before this equipment is placed into service and

periodically thereafter. Procedures used in gaseous

fuel leakage tests must comply strictly with applicable

fuel gas codes. Do not use flame or any source of heat

to test for gas leaks. No gas leakage is permitted. LP

gas is heavier than air and tends to settle in low areas.

Natural gas is lighter than air and tends to settle in high

places. Even the slightest spark can ignite these fuels

and cause an explosion.

Use a flexible length of hose between the Generator fuel

connection and rigid fuel lines is required. This will help

prevent line breakage that might be caused by vibration or if

the Generator shifts or settles. The flexible fuel line must be

approved for use with gaseous fuels.

Flexible fuel line should be kept as straight as possible between

connections. The bend radius for flexible fuel lines is nine (9)

inches. Exceeding the bend radius can cause the fittings to

crack.

TRANSFER SWITCH / LOAD CENTER

Electrical code requires the use of a transfer switch, to prevent

electrical feedback between the Utility and Standby power

sources, and to transfer electrical loads from one power supply

to another safely. See Section 3.1 for further information.

POWER SOURCE AND LOAD LINES

The Utility supply lines, the Standby supply lines, and electrical

Load lines must all be connected to the proper terminal lugs in

the transfer switch. In single phase systems only with a 2-pole

CONTACTOR the following installation procedure applies.

Connect the two Utility source (hot) lines to the CONTACTOR

terminal lugs labeled N1 and N2. Connect the Standby source

(hot) lines to the CONTACTOR terminal lugs labeled E1 and E2.

Connect the Load lines to the CONTACTOR terminal lugs labeled

T1 and T2. Connect the Utility, Standby, and Load Neutral lines

to the NEUTRAL block in the transfer switch.

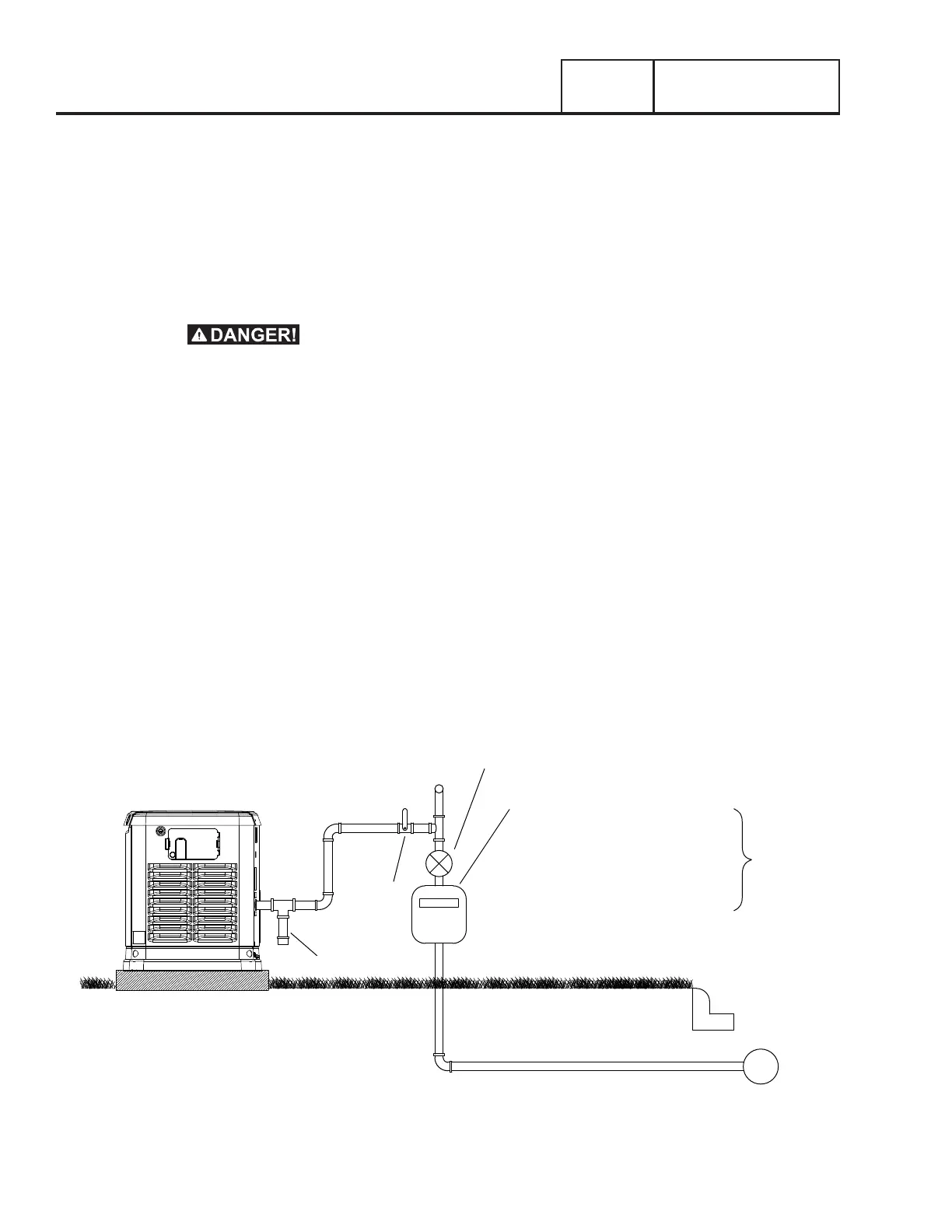

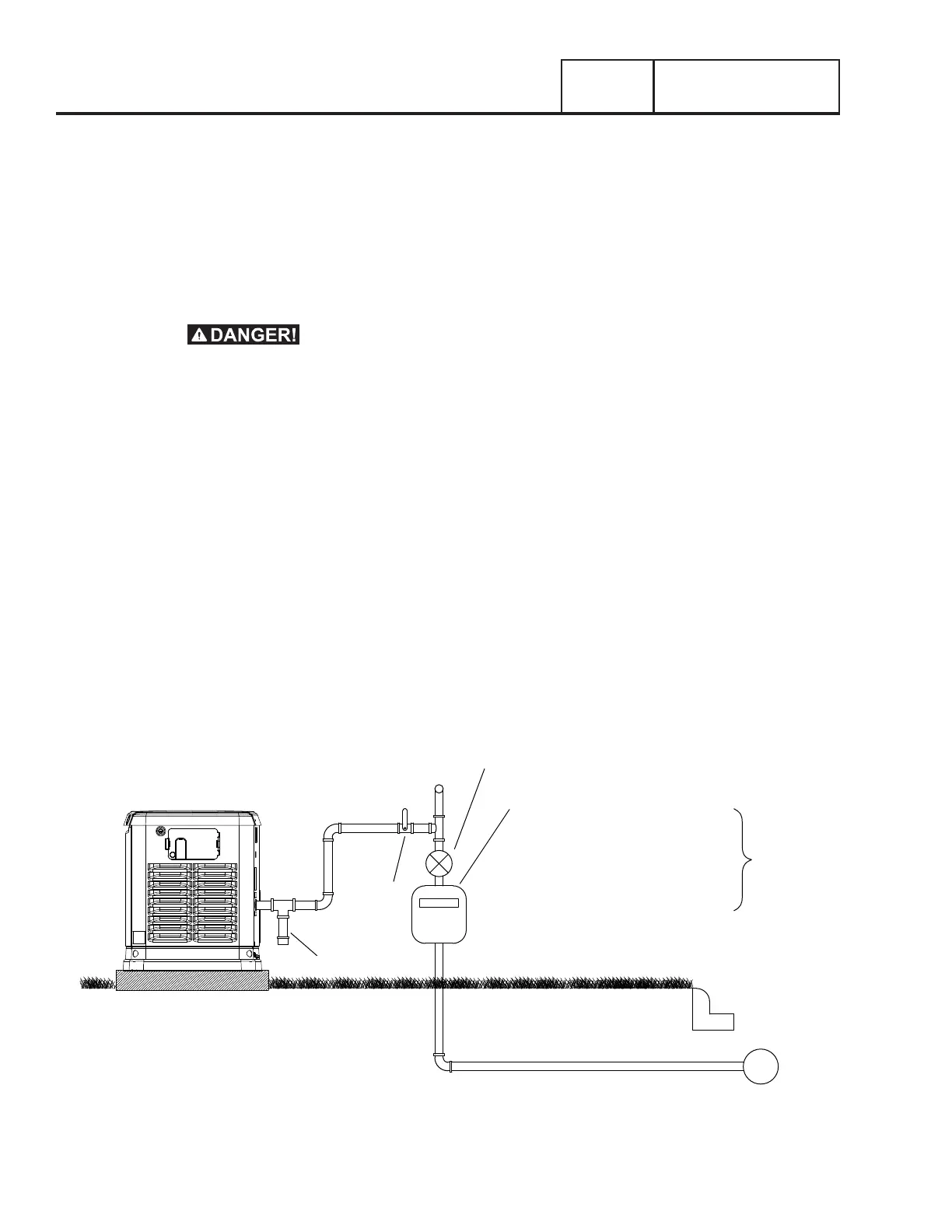

0000001

GAS MAIN

2-5 PSI

5-7” WC REGULATOR

TO HOUSEHOLD

GAS METER CAPABLE

+HOUSEHOLD APPLIANCES

FUEL FLOW OF:

OF PROVIDING NATURAL GAS

SAFETY

SHUT OFF

VALVE

TRAP

(BASED ON 1000 BTU/CU FT)

BTU/HOUR

140,000 (7 kW)

156,000 (9 kW)

215,000 (12 kW)

220,000 (13 kW)

245,000 (15kW)

261,000 (16 kW)

294,000 (18 kW)

Figure 8. Proper Fuel Installation

NATURAL GAS FUEL INTERCONNECTIONS

Loading...

Loading...