PART 4

ENGINE/DC CONTROL

Page 124

Section 4.5

Diagnostic Tests

3. Disconnect Wire 14 from the fuel solenoid (FS).

4. Connect the positive test lead to the disconnected Wire 14

from Step 3 and connect the negative test lead to a clean

frame ground.

5. Set AUTO-OFF-MANUAL switch to the MANUAL position.

The meter should indicate battery voltage.

a. If battery voltage is indicated, refer back to flow chart.

b. If battery voltage is not measured, proceed to Step 6

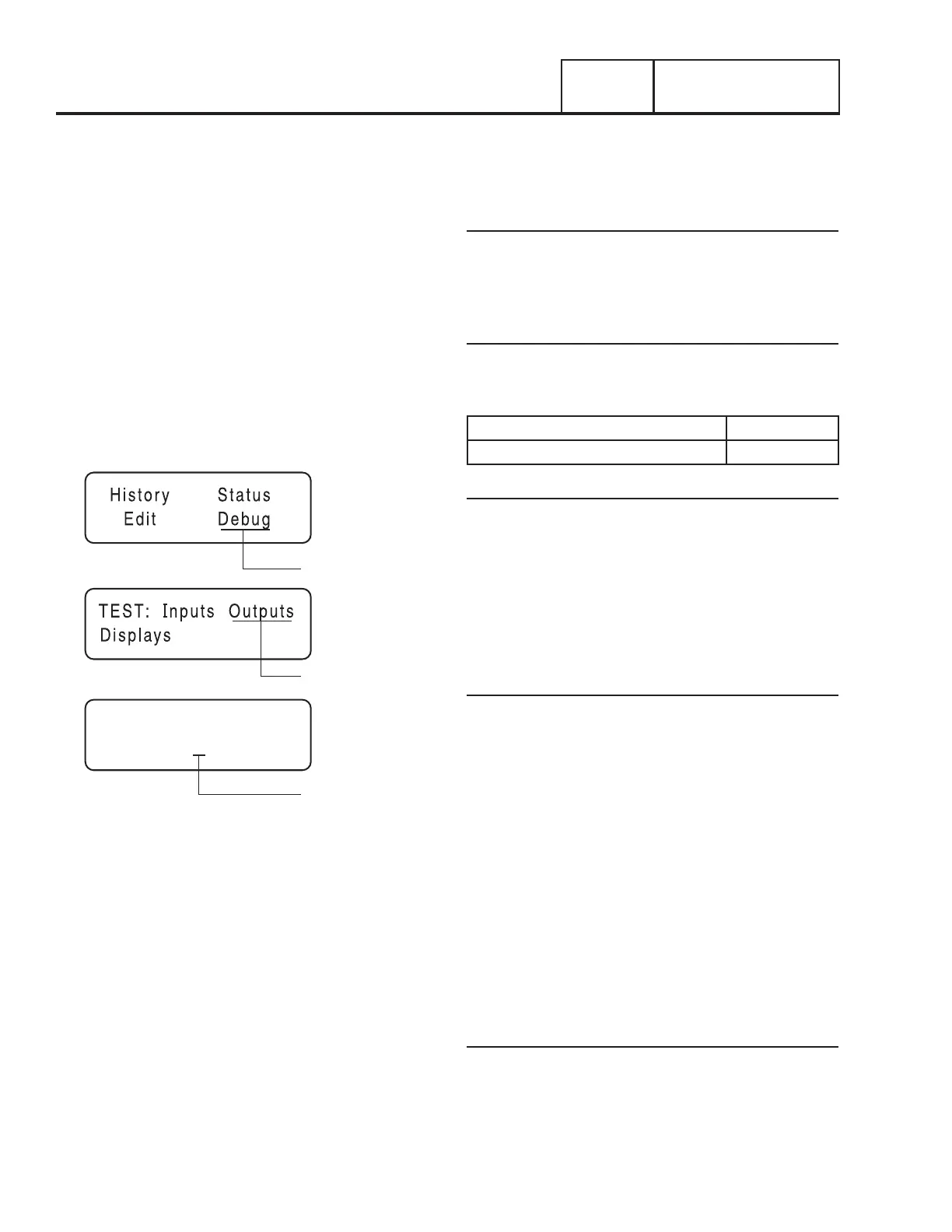

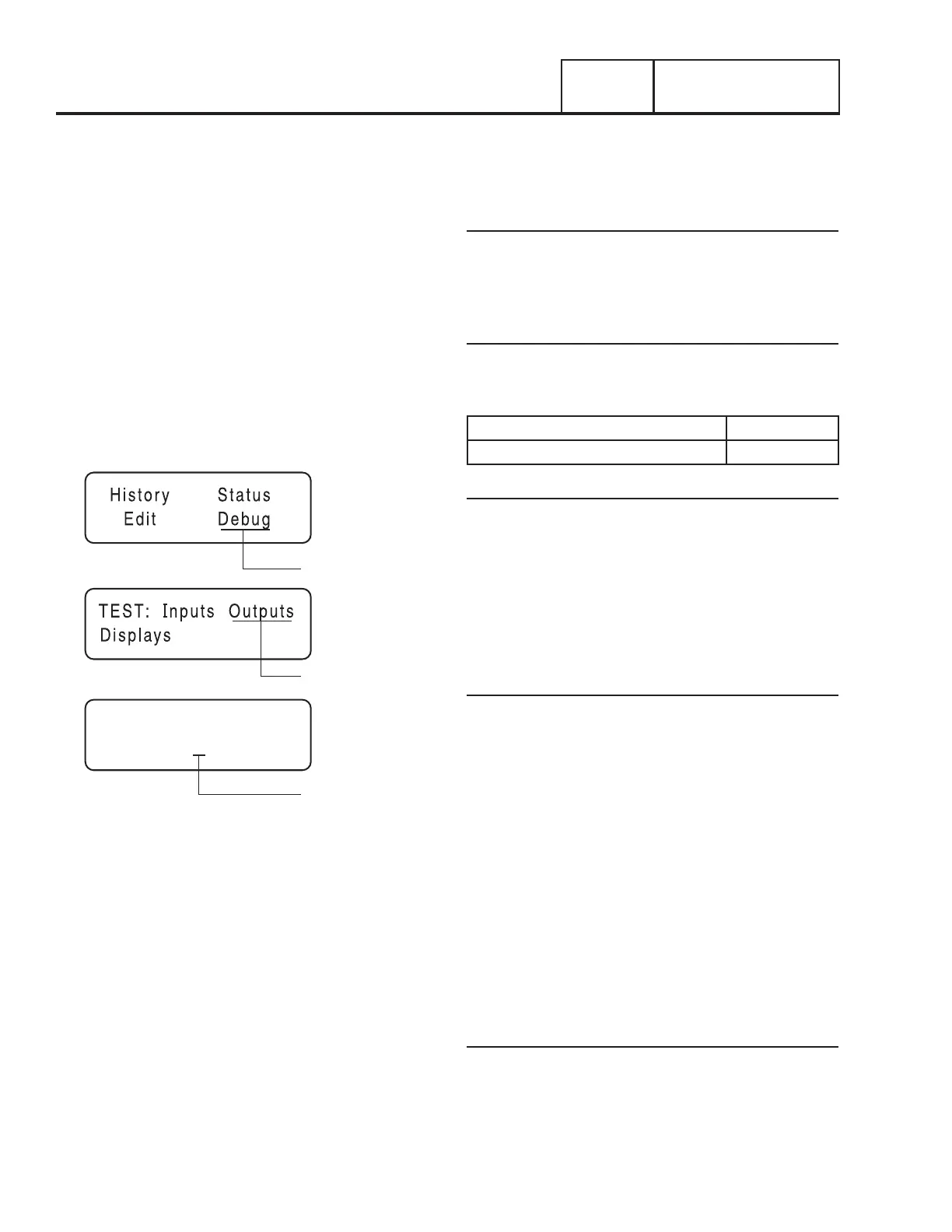

6. Navigate to the Digital Output display.

7. Press “ESC” until the display screen is present.

8. Press the right arrow key until “Debug” is flashing. Press

“Enter”.

9. Press the right arrow key until “Outputs” is flashing. Press

“Enter”.

DEBUG

OUTPUTS

OUTPUT 5

OUTPUTS 1 - 8:

1 0 1 1 0 0 0 1

Figure 127. The Home Page, Debug and Output Screens

10. Output 5 is Wire 14 out from the controller. If the controller

is functioning properly, Output 5 will change from a “0” to

a “1” while the unit is cranking.

a. If the VOM did NOT indicate voltage in Step 5 and

output did not change in Step 10, replace the controller.

b. If the VOM did NOT indicate voltage in Step 5 and the

output in Step 10 changed, proceed to Step 11.

11. Disconnect the 7.5 amp Fuse

12. Disconnect the J4 connector from the controller.

13. Set a VOM to measure resistance.

14. Connect one meter test lead to Wire 14 that was

disconnected in Step 3 and connect the other meter test

lead to Wire 14 at Pin 9 J4 (Wire 14). See Section 4.1

“Connector Pin Descriptions”.

a. If the VOM indicated CONTINUITY repeat Step 5 and

then retest.

b. If CONTINUITY is not measured, repair or replace Wire

14 between the J4 Connector and the fuel solenoid.

Results

Refer back to flow chart

TEST 52 – CHECK FUEL SOLENOID

Discussion

In Test 67, if battery voltage was delivered to Wire 14, the

fuel solenoid should have energized open. This test will verify

whether or not the fuel solenoid is operating.

Fuel Solenoid FS1 Nominal Resistance 27-33 ohms.

Fuel Solenoid FS2 Nominal Resistance 29 ohms.

Procedure: 8 and 12-20kW Units

1. Install a manometer to Port 2 on the fuel regulator. See

Figure 124 or Figure 126.

2. Set the AUTO-OFF-MANUAL Switch to MANUAL.

3. Proper gas pressure should be measured during cranking.

If gas pressure is measured, the fuel solenoid is operating.

If gas pressure is not measured, repair or replace the fuel

solenoid.

Procedure: 10kW Units

1. Remove the hose from fuel solenoid (FS2) and install a

manometer to Port 2 on the fuel regulator. See Figure 125.

2. Set the AUTO-OFF-MANUAL Switch to MANUAL.

3. Proper gas pressure should be measured during cranking.

If gas pressure is measured, both fuel solenoids are

operating. Discontinue testing.

4. If gas pressure was not measured in Step 3, remove fuel

solenoid FS2 and install a manometer to the bottom port

of the fuel regulator.

5. Set the AUTO-OFF-MANUAL Switch to MANUAL.

6. Proper gas pressure should be measured during cranking.

If gas pressure is measured, fuel solenoid FS1 is

operating. Replace fuel solenoid FS2. If gas pressure is

not measured, repair or replace fuel solenoid FS1.

Results

If fuel pressure was measured in any of the preceding tests it

indicates that the fuel solenoid is operating properly. Refer back

to the flow chart for the next test.

Loading...

Loading...