PART 1

GENERAL INFORMATION

Page 16

Section 1.3

Preparation Before Use

INTRODUCTION

It is the responsibility of the installer to ensure that the Generator

installation was performed properly. A careful inspection

must be performed when the installation is complete. All

applicable codes, standards, and regulations pertaining to

such installations must be strictly complied with. In addition,

regulations established by the Occupational Safety and Health

Administration (OSHA) must be complied with as well.

Prior to initial startup of the unit, the installer must ensure

that the Generator has been properly prepared for use. This

includes the following:

•An adequate supply of the correct fuel must be available for

Generator operation.

•The engine must be properly serviced with the recom-

mended oil.

•With liquid propane (LP), use only the “vapor withdrawal”

system. This type of system uses the vapors formed above

the liquid fuel in the storage tank.

The engine has been fitted with a fuel carburetion system that

meets the specification of the 1997 California Air Resources

Board for tamper-proof dual fuel systems. The unit will run

on natural gas or LP, but it has been factory set and tested to

run on natural gas. When the change from natural gas to LP is

needed, the fuel system needs to be re-configured. See Section

1.4 “Reconfiguring the Fuel System” for further information.

Recommended fuels should have a British Thermal Unit (BTU)

content of at least 1,000 BTU’s per cubic feet for natural gas; or

at least 2,520 BTU’s per cubic feet for LP. Ask the fuel supplier

for the BTU content of the fuel.

Recommended fuel pressures for natural gas and liquid propane

vapor (LPV) are as follows:

LPV NG

Minimum Water Column 10 inches 5 inches

Maximum Water Column 12 inches 7 inches

Note: All pipe sizing, construction and layout must comply

with NFPA 54 for natural gas applications and NFPA 58 for

liquid propane applications. After installation, verify that

the fuel pressure NEVER drops below five (5) inches water

column for natural gas or ten (10) inches water column for

LPV.

Prior to installation of the Generator, the installer should

consult local fuel suppliers or the fire marshal to check

codes and regulations for proper installation. Local codes

will mandate correct routing of gaseous fuel line piping

around gardens, shrubs and other landscaping to prevent

any damage.

Special considerations should be given when installing the unit

where local conditions include flooding, tornados, hurricanes,

earthquakes and unstable ground for the flexibility and strength

of piping and their connections.

Use an approved pipe sealant or joint compound on all threaded

fittings.

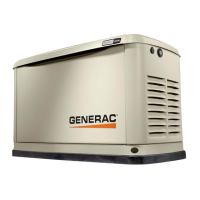

Table 2. Fuel Pipe Sizing

Natural Gas

Table values are maximum pipe run in feet

KW 0.75" 1" 1.25" 1.5" 2" 2.5" 3"

7-8 55 200 820

10 20 85 370 800

13-14 10 50 245 545

15-17 40 190 425

20 20 130 305 945

Liquid Propane Vapor

Table values are maximum pipe run in feet

KW 0.75" 1" 1.25" 1.5" 2" 2.5" 3"

7-8 165 570

10 70 255 1000

13-14 45 170 690

15-17 25 130 540

20 15 115 480

Notes:

•Pipe sizing is based on 0.5” H20 pressure drop

•Sizing includes a nominal number of elbows and tees

•Please verify adequate service and meter sizing

Gaseous fuels such as natural gas and LPV are highly

explosive. Even the slightest spark can ignite such

fuels and cause an explosion. No leakage of fuel is

permitted. Natural gas, which is lighter than air, tends

to collect in high areas. LP gas is heavier than air and

tends to settle in low areas.

Note: Code requires a minimum of one approved manual

shutoff valve installed in the gaseous fuel supply line. The

valve must be easily accessible. Local codes determine

the proper location.

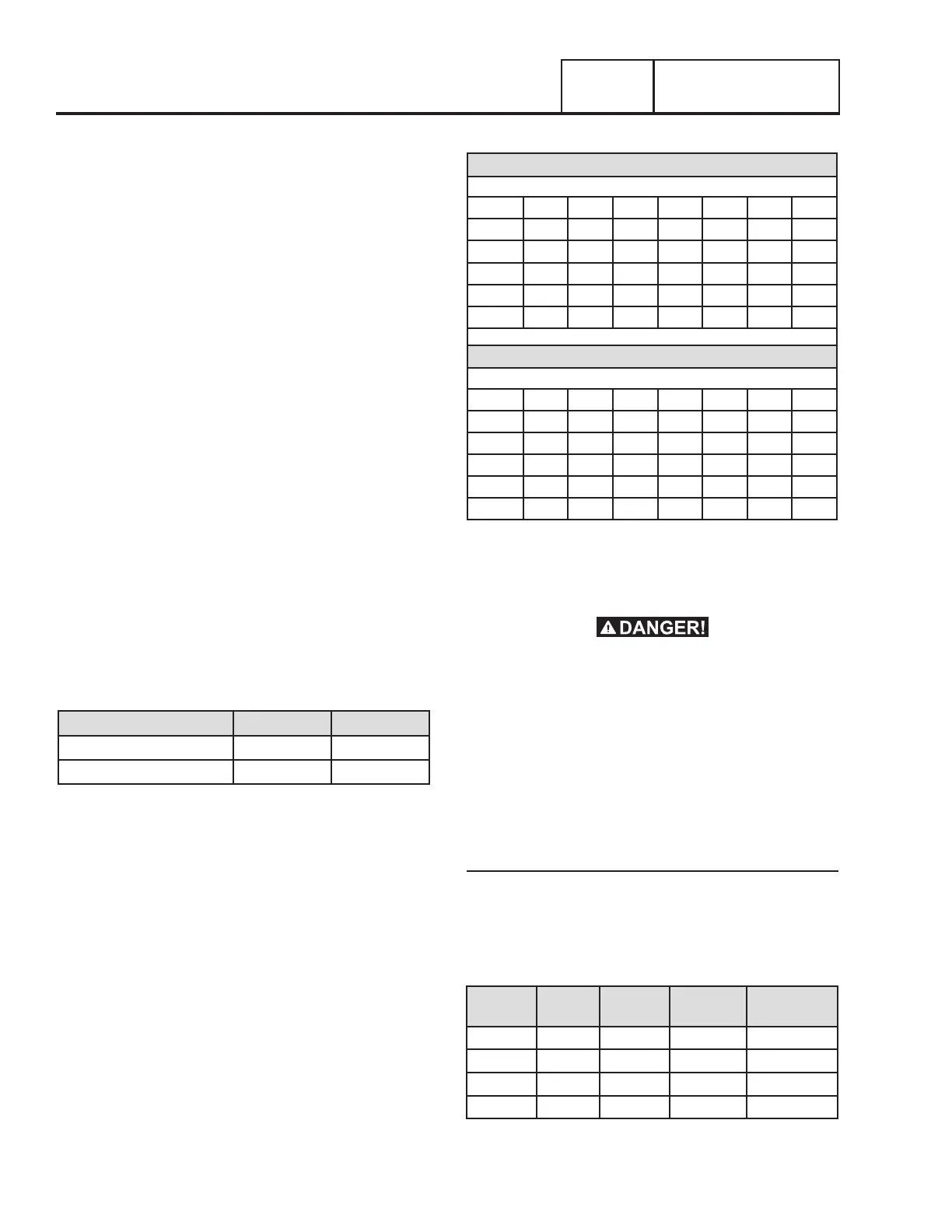

Fuel Consumption

The fuel consumption rate for individual kW ranges are listed

in the Specifications section at the front of this manual. Table

3 shows standard fuel consumption rates based on 4 different

kW ranges.

Table 3. Standard Fuel Consumption Rates

Load (kW) BTU / Hr LP Gal

/ Hr

NG FT3 / Hr NG Therms

/ Hr

5 110,000 1.2 110 1.1

10 176,400 2 156 1.6

15 231,800 2.5 220 2.2

20 267,100 2.8 262 2.6

Note: Typical fuel consumption based on a Generator 100%

loaded.

Loading...

Loading...