3 Brief Introduction to the ARAMIS System

ARAMIS is a non-contact optical 3D measuring system.

The system analyzes, computes and documents object deformations, rigid

body movements and the dynamic behavior of measuring objects.

The ARAMIS measuring system is a stereo camera system for analyzing

statically or dynamically loaded parts. Precise 3D coordinates are captured

and then metrologically evaluated.

With ARAMIS, you can also measure in 2D. Then, you capture the images

for the measurement series with only one camera.

Thus, you get the possibility to capture images, for example, in a narrow

neighborhood or through thick window panes.

The system determines the 3D coordinates of discrete points over a certain

period of time. The temporal resolution depends on the frequency used

for the image recording. The options of the camera frequencies depend

on the sensor used or the cameras used.

Stereo camera setup

•

You can determine 3D coordinates.

•

You can measure any objects in 3D.

Single camera system

•

You can determine only 2D coordinates.

•

You can measure flat objects.

Info

You can see a detailed comparison of 2D and 3D measurements in the

GOM webinar “2D and 3D – Image Correlation in Materials and Compo‐

nents Testing”. You can download the webinar from the GOM Service

Area or view it on the GOM Metrology YouTube Channel.

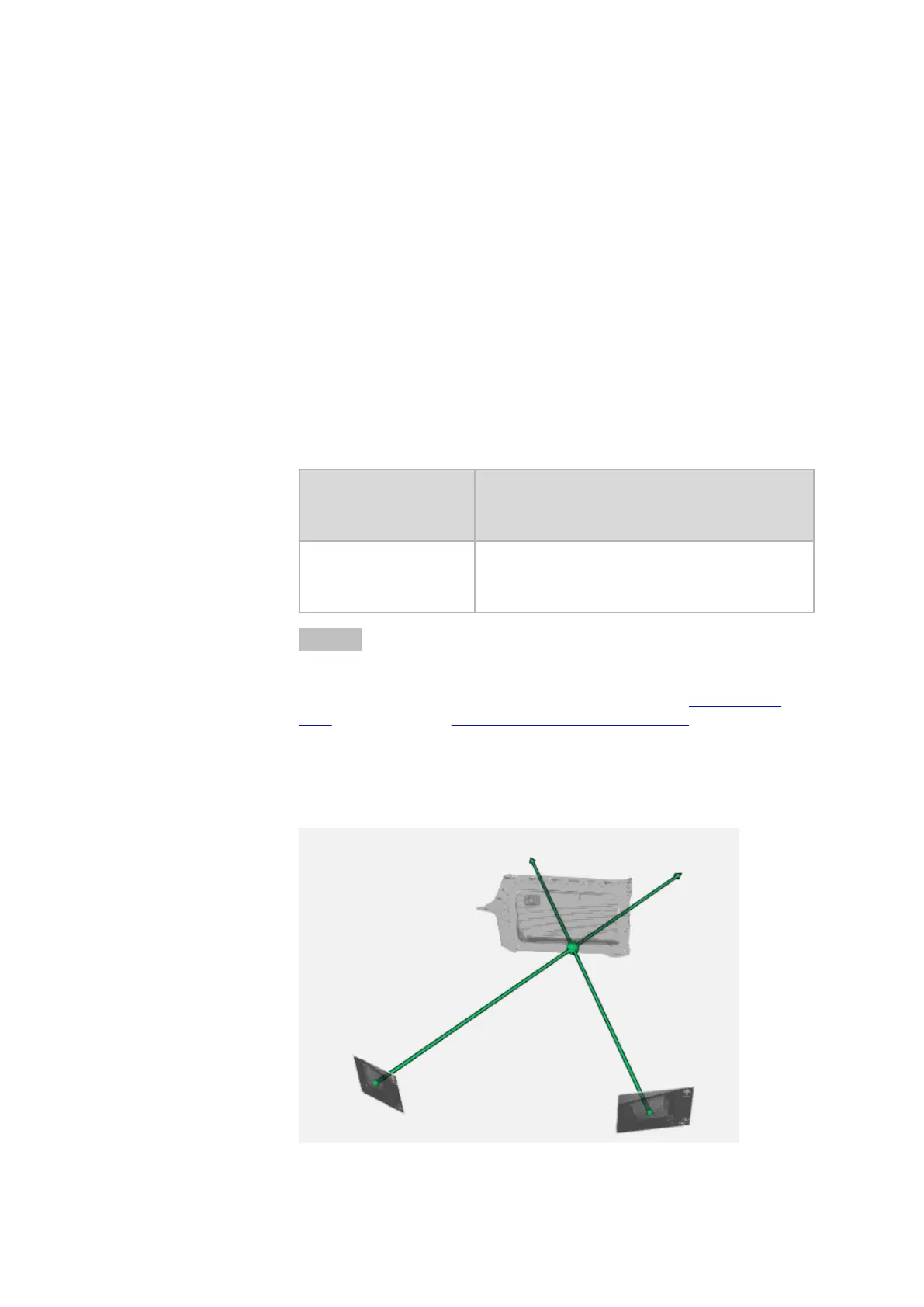

The software computes coordinates in 3D space. The software clearly

assigns the points from the camera images to each other. To compute the

3D coordinates, the software needs reference points applied on the part

or an applied stochastic pattern.

Fig. 1: Principle of the digital image correlation

0000001503_002_EN_02-12-2019 Page 8 (56)

Loading...

Loading...