Model G1026 (Mfd. Since 10/13)

-29-

Changing Cutter

Rotation

Figure 33. FOR/REV switch.

Always check the direction of the cutter rota-

tion before any shaping operation.

The G1026 is equipped with a FOR/REV (forward

and reverse) switch, as shown in Figure 33. In

most cases, the shaper should be run in the FOR

direction.

In some instances, it will be necessary to flip the

cutter over and reverse the cutter rotation.

Whenever possible, mount the cutter so the stock

is milled on the bottom side (the side away from

the operator). This does a better job and it is safer

for the operator. Refer to Rub Collars, Page 34.

The Model G1026 Shaper is equipped with a spe-

cial high-speed V-belt. It is designed to withstand

the vibration and sudden shock loads associated

with the operation of a shaper.

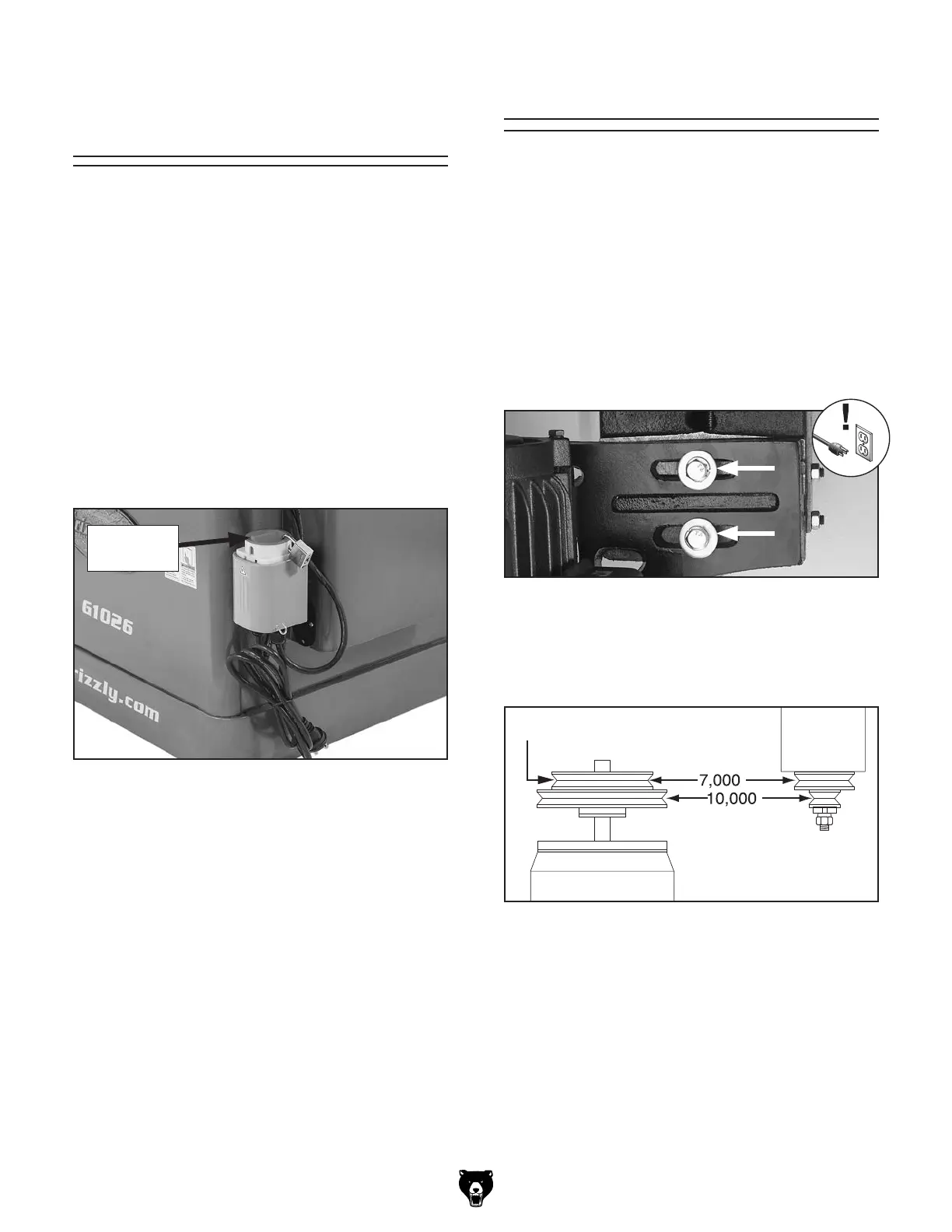

To change spindle speeds:

1. DISCONNECT MACHINE FROM POWER!

2.

Remove the rear cover, then loosen the two

motor mount bolts shown in Figure 34 and

slide the motor toward the spindle assembly.

4.

Slide the motor back into position and tighten

the belt. When the belt is properly tensioned,

there should be approximately

1

⁄4" of deflec-

tion in the center of the belt when you press

it with your thumb.

5.

Tighten the motor mount bolts.

6. Spin the pulley to ensure proper tracking.

7. Re-install the rear cover.

Speed Changes

Figure 34. Location of motor mount hex bolts.

Figure 35. Speed change belt positions.

Sheave

3. Move the V-belt to a sheave on the motor and

spindle pulleys to select the desired speed

(see Figure 35.)

FOR/REV

Switch

Loading...

Loading...