Model G1026 (Mfd. Since 10/13)

-35-

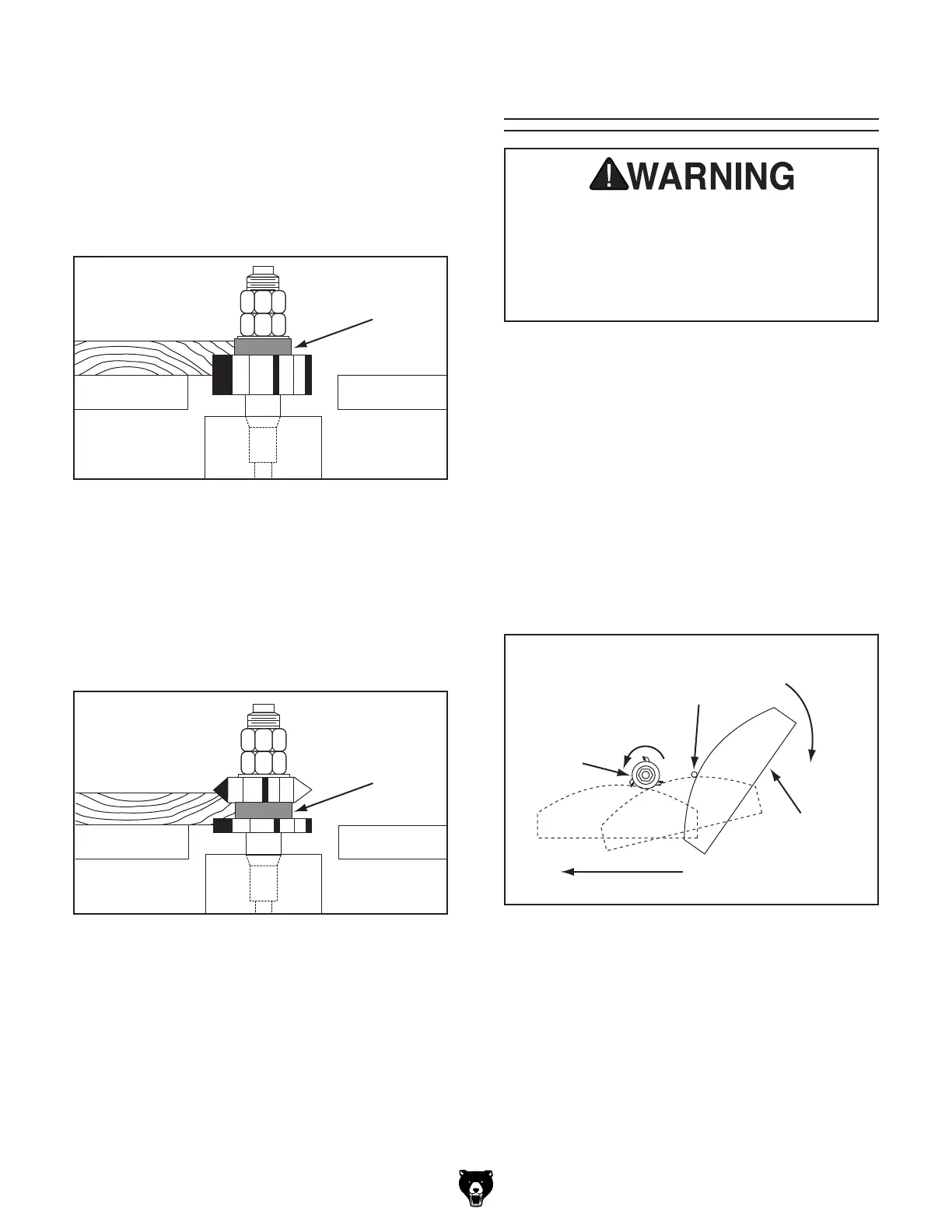

2. Above the cutter: When the rub collar is

used above the cutter, the cut cannot be

seen (see Figure 47). This offers some

advantage—the stock is not affected by slight

variations in thickness and accidental lifting

will not damage the workpiece. Simply cor-

rect any change in height by repeating the

operation.

Rub

Collar

Figure 47. Cutting with rub collar above cutter.

3. Between two cutters: Using a rub col-

lar between two cutters has the distinct

advantage of performing two cuts at once or

eliminating the need to change cutters for two

different operations (see Figure 48). Notice

that part of the edge is left uncut. The uncut

portion rides on the rub collar.

Rub

Collar

Figure 48. Using rub collar between cutters.

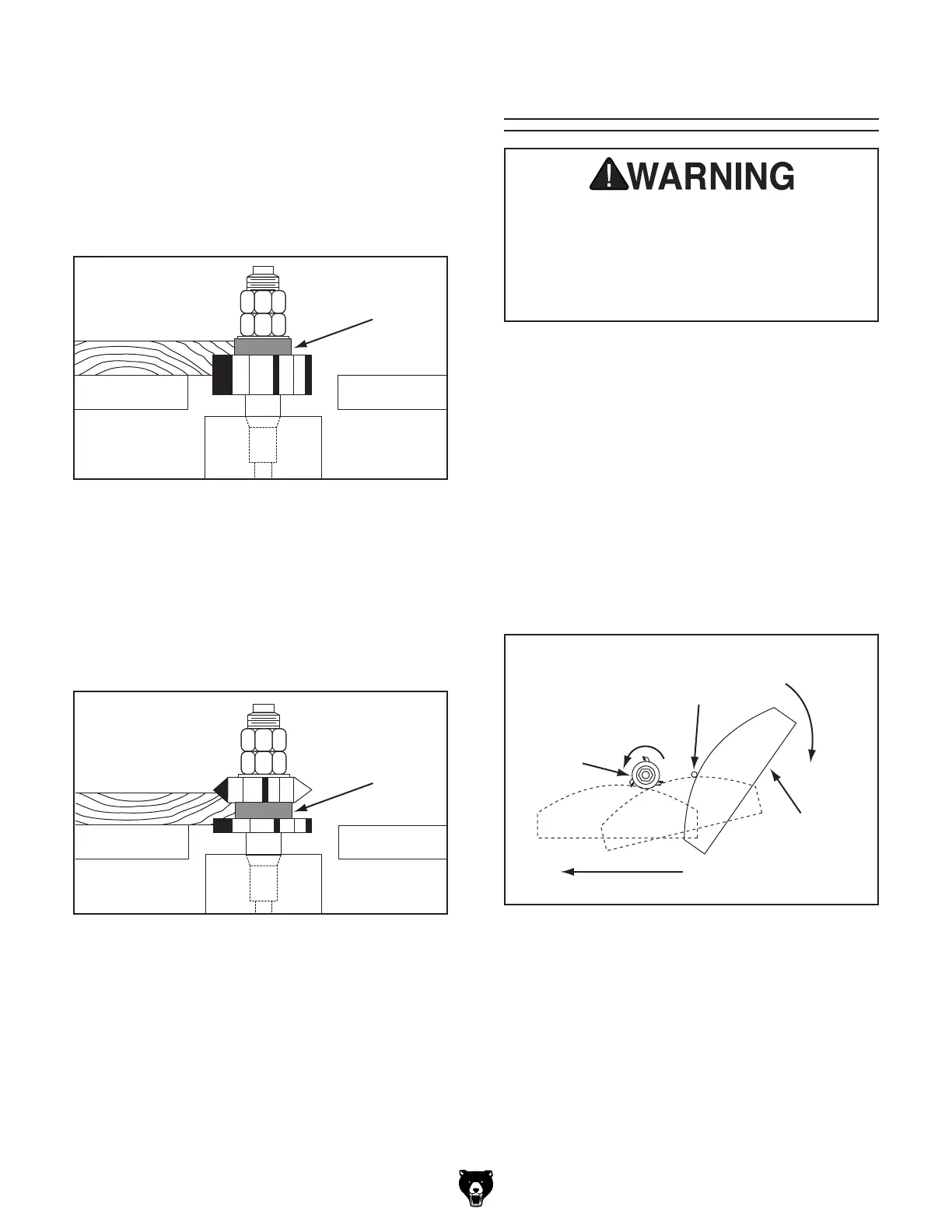

Irregular or freehand shaping takes a high degree

of skill and dexterity. The fence assembly is not

used in irregular shaping, so rub collars must be

used. (See Rub Collars on Page 34).

When doing freehand work, a starting pin

must be used. The purpose of the starting pin

is to support the workpiece during the beginning

of the cut. Your shaper is supplied with a starting

pin that can be placed in one of the holes located

in the shaper table. The work should be placed in

the starting position using the starting pin for sup-

port, as shown in Figure 49.

Figure 49. Using a starting pin for irregular

shaping.

Workpiece

Feed Direction

Swing

Starting Pin

Rub

Collar

R

o

t

a

t

i

o

n

Next, swing the work into the cutter while hold-

ing the workpiece firmly against the starting pin.

After the cut has been started, the work should be

swung away from the starting pin and is support-

ed just by the rub collar, as shown by the broken

line positions shown in Figure 49.

ALWAYS FEED AGAINST THE ROTATION OF

THE CUTTER.

Irregular Shaping

Freehand shaping greatly increases the

chance that the operator may lose control of

the workpiece, which could result in serious

personal injury. Therefore, a starting pin or

support MUST be used to start an irregular

shaping operation.

Loading...

Loading...