Model G1026 (Mfd. Since 10/13)

-19 -

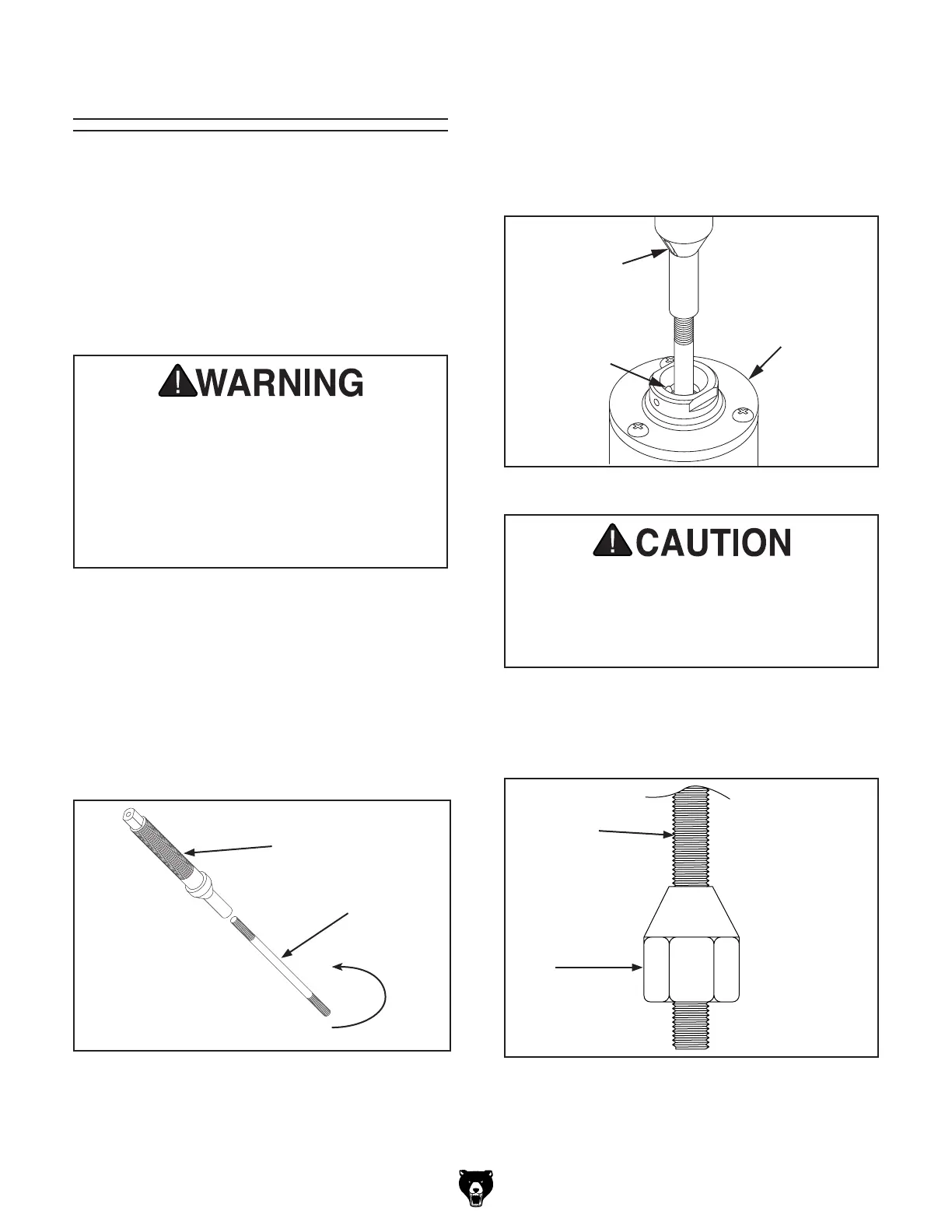

Each of the three spindles that come with the

Model G1026 is sized to work efficiently with dif-

ferent sized cutters and spacers. The spindles

must be inserted correctly and remain securely

locked in the machine in order to produce qual-

ity work. When installing and changing spindles,

make sure the spindle seats snugly and that there

is enough drawbar threaded into the bottom of the

spindle to safely secure it in place.

To install a spindle:

1.

Remove the hex nuts from the spindle and

the drawbar nut from the drawbar.

2. Thread the drawbar approximately 10-15

turns into the bottom of the spindle. The

drawbar has two threaded ends. One of them

remains exposed (see Figure 14).

Figure 14. Spindle and drawbar.

10-15 Turns

Spindle

Drawbar

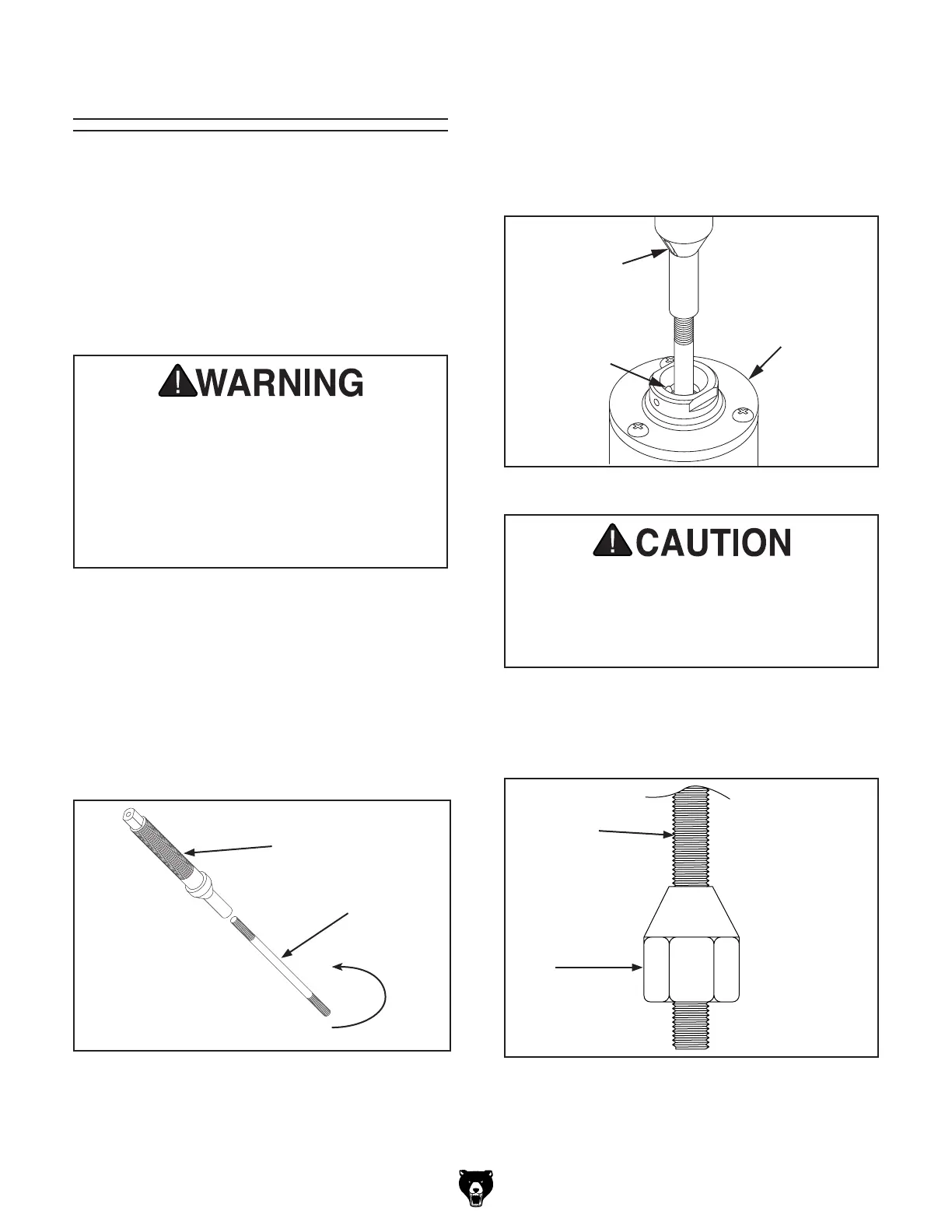

3.

Place the spindle/drawbar into the spindle

cartridge at the top of the table. Line up

the keyway on the spindle with the locating

pin at the top of the spindle cartridge (see

Figure 15). You will feel the spindle seat

itself.

Incorrect assembly can allow the spindle

and cutter to fly off the machine, which

could cause injury or death. Make certain

the spindle is properly assembled before

operating the Shaper. If you are uncertain of

any aspect of this assembly, please review

these instructions again or contact our

Customer Service.

Spindle

Keyway

Pin

Spindle

Cartridge

Figure 15. Inserting the spindle into place.

4. Thread the drawbar nut, tapered side up, onto

the bottom of the drawbar until it stops below the

spindle housing cartridge (see Figure 16).

Figure 16. Nut threaded onto drawbar.

Make sure the spindle keyway and pin are

aligned and properly seated before tighten-

ing the drawbar nut. Improper assembly can

create an unsafe condition and possible

injury to the operator.

Drawbar

Nut

Loading...

Loading...