-32-

Model G1026 (Mfd. Since 10/13)

The fence assembly is a two-piece, independently

adjustable system. When removing material from

the whole face of your workpiece, the outfeed

fence can be adjusted to provide support for the

workpiece as it passes over the cutter, or it can be

set up for partial face removal.

When removing material from the entire board

face, observe the following steps:

1.

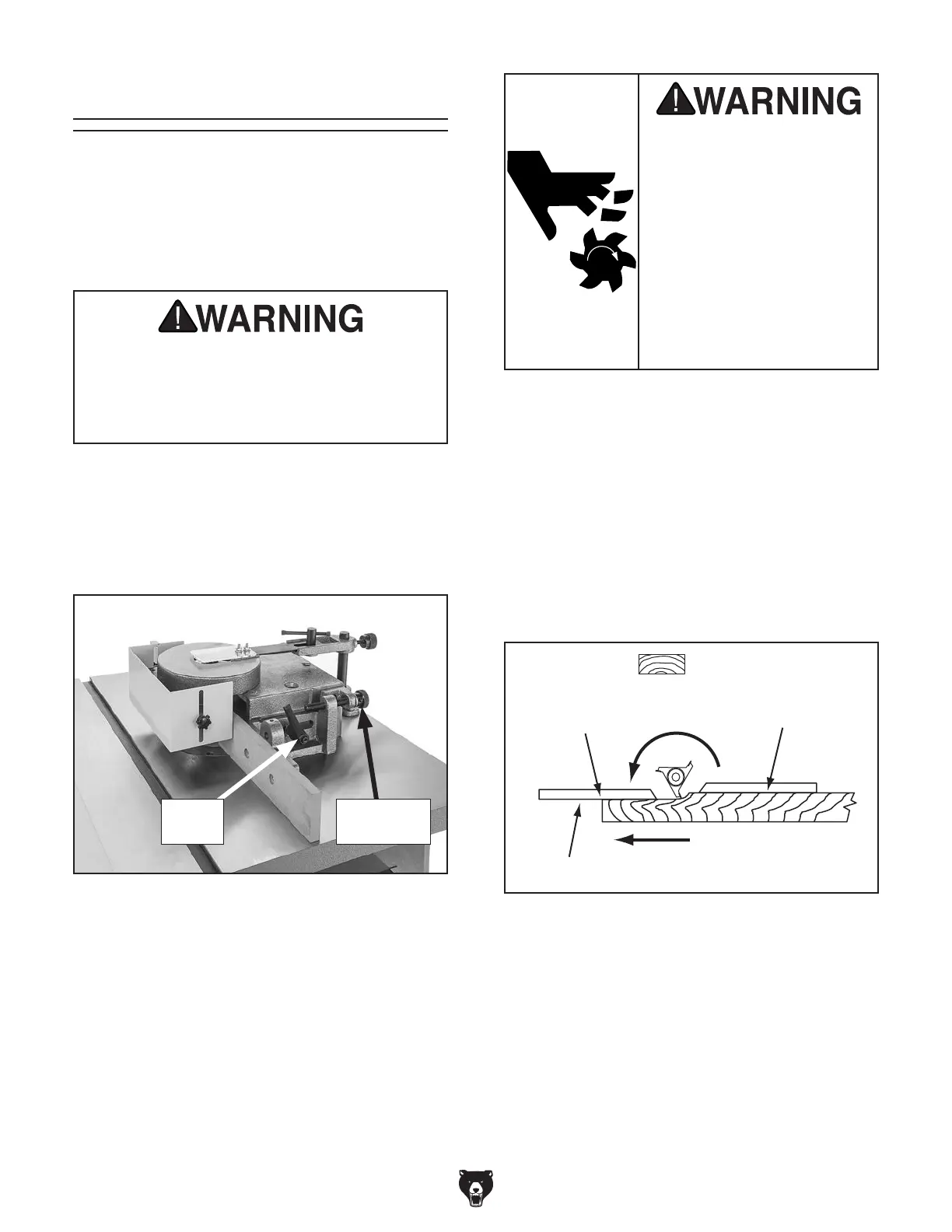

Loosen the locking handles that hold the

fences in place (see Figure 41).

4.

Lock the infeed fence in position with the lock

handle.

5. Turn the shaper ON and advance a test

sample of the desired cut about 8'', then stop.

Swing the test piece away from the cutter and

turn the machine OFF.

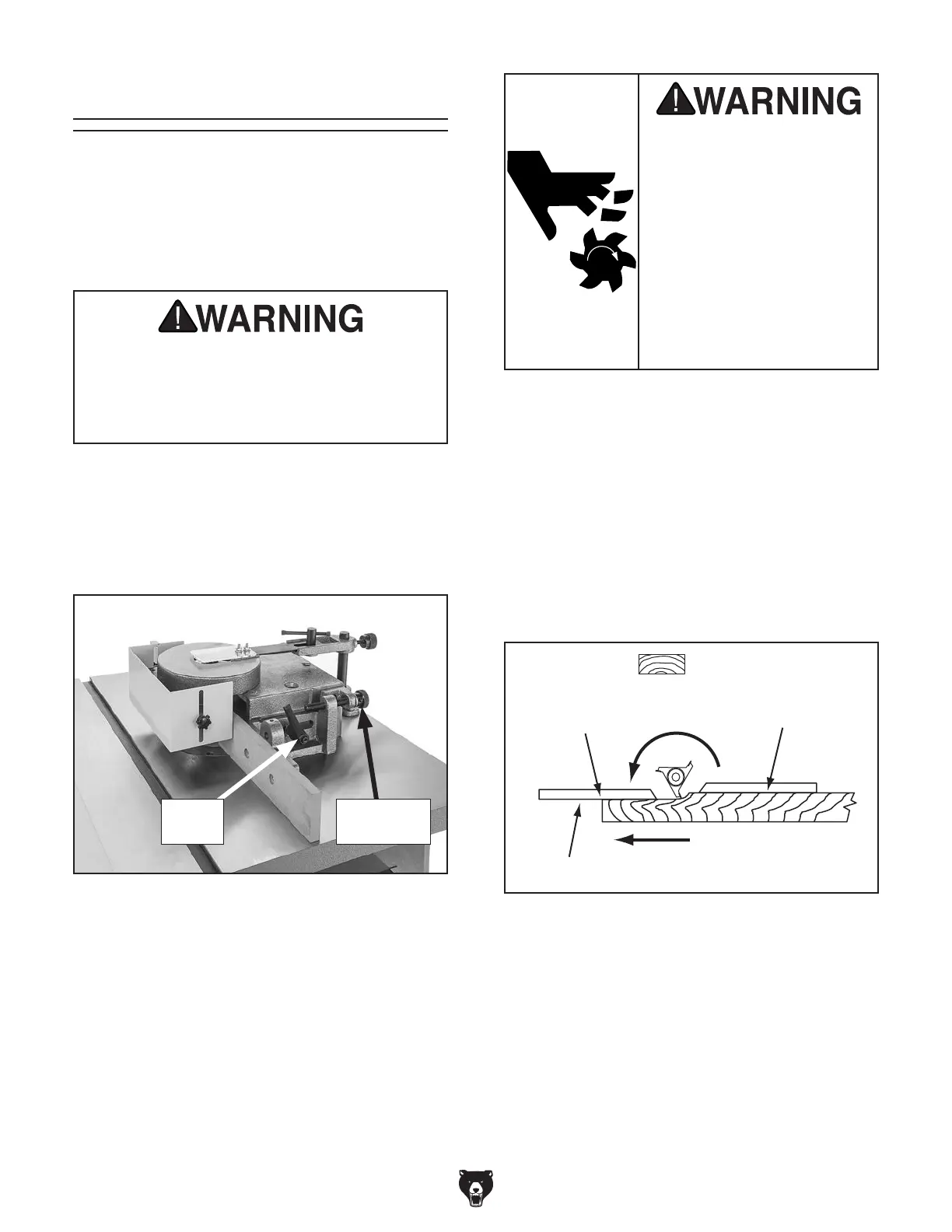

6.

When the cutter comes to a complete stop,

adjust the outfeed fence to support the new

profiled edge, as shown in Figure 42.

Figure 41. Fence adjustments.

Straight Shaping

Attempting to operate the shaper without

proper knowledge of the machine could

cause serious injury or death! Read through

the entire manual carefully before attempt-

ing to make any cuts with your shaper.

2. Adjust the infeed fence by turning the knurled

adjustment knob until the workpiece contacts

the cutter in the desired location.

3.

Use a test piece at least 24" long to deter-

mine the best setting.

Figure 42. Support workpiece as it is fed.

End View

Direction of Feed

Outfeed

Fence

Supported

Infeed

Fence

All guards MUST be

installed on shaper before

operating it. Shapers are

dangerous machines that

can quickly cause serious

injury if some kind of guard

is not used. To protect

yourself, read and follow

entire instruction manual

carefully and do addition-

al research on shop made

guards and safety jigs.

Lock

Handle

Adjustment

Knob

Loading...

Loading...