GSK CNC Equipment Co., Ltd.

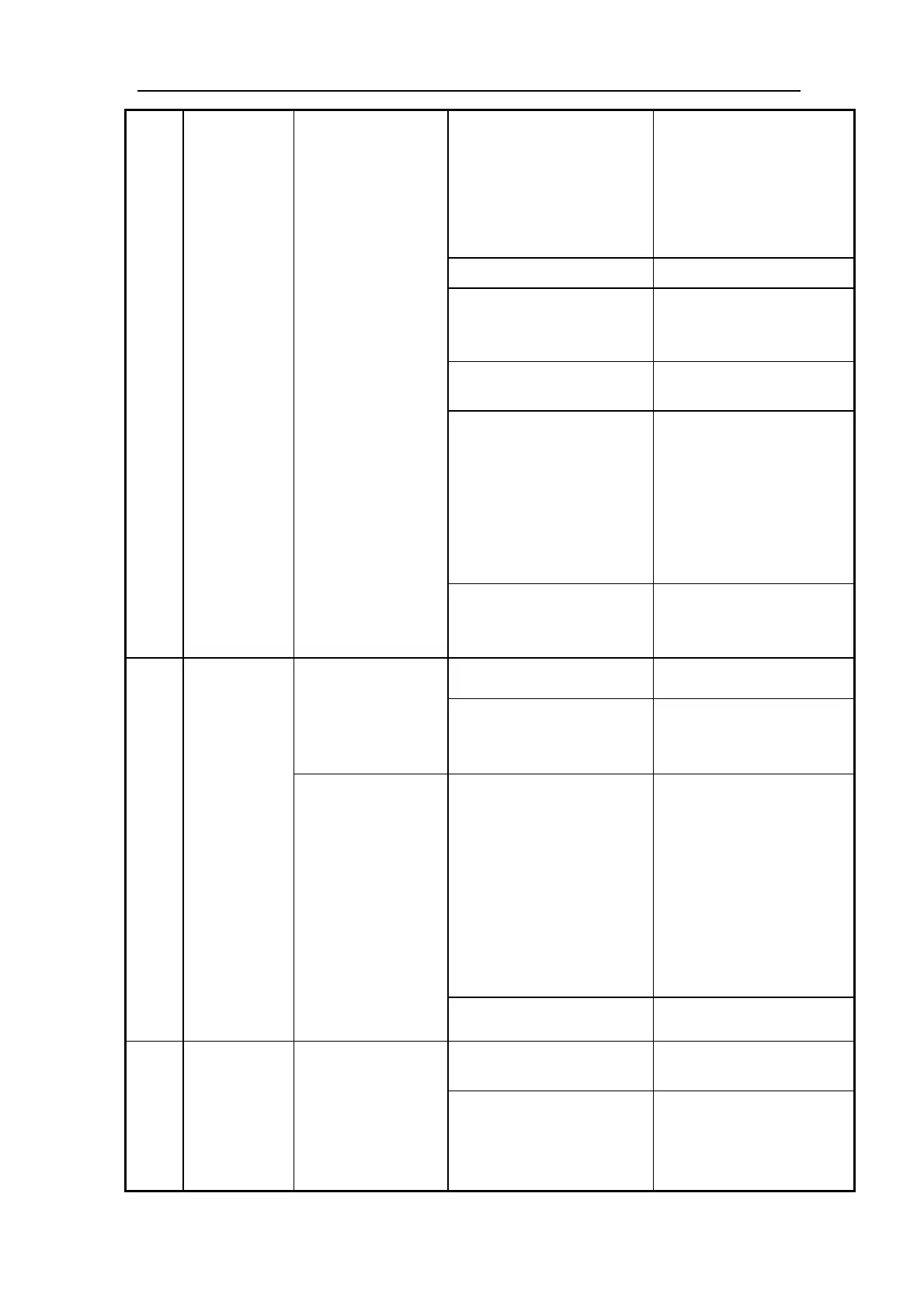

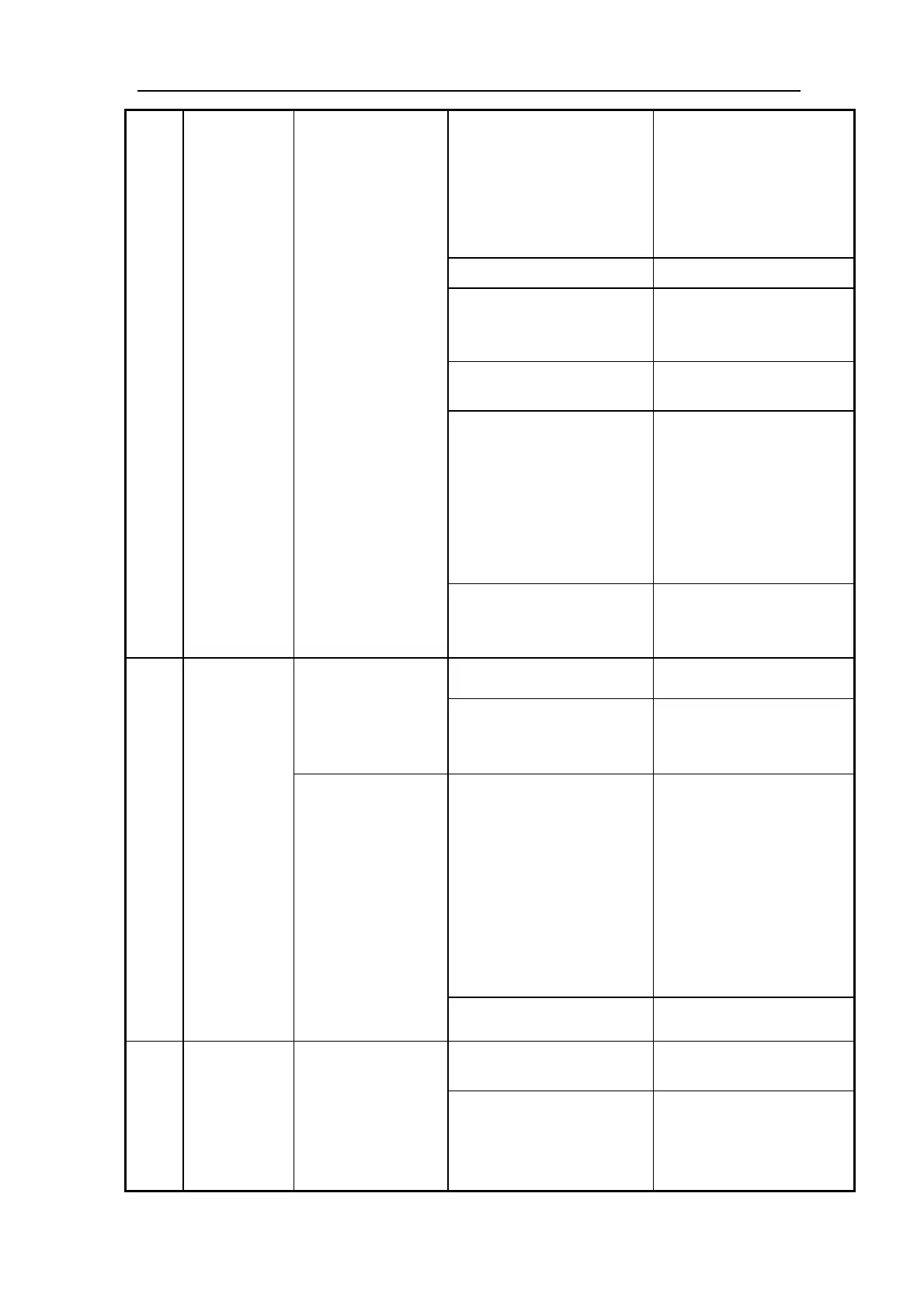

60

① U, V, W lead wires of

motor are not connected

correctly.

② Lead wires of encoder

cable are not connected

correctly.

① Connect them correctly.

① Encoder fault

① Change the servo motor.

① The orientation oversize

detecting setting range is too

small.

① Increase the setting range.

① The orientation proportional

gain is too small.

① Increase the gain.

① Torque is not enough..

① Check the torque limit

value.

② Reduce the load

capacity..

③ Change the driver and

motor with larger power

ones.

the motor doesn’t

rotate after switching

on the main power

supply and the control

wires and inputting

instruction pulse

① Instruction pulse frequency

is too high.

① Reduce the frequency.

① Circuit board is at fault.

① Change the servo driver.

Occurring in switching

on control power

supply

① Cable is broken.

② Internal temperature relay

of motor is damaged.

① Check the cable.

② Check the motor.

① Motor is overloaded.

① Reduce the load.

② Reduce the start-stop

frequency.

③ Reduce the torque limit

value.

④ Reduce the related gain.

⑤ Change the driver and

motor with larger power

ones.

Err-5

Motor

overheated

Occurring in motor

running

① Motor interior is at fault. ① Change the servo motor.

The motor is chucked

mechanically.

Check the mechanical part.

Err-6

Speed error

too big or too

long saturation

time fault of

speed

amplifier

Occurring in motor

running

The load is too big.

① Reduce the load.

② Change the driver and

motor with larger power

ones.

Loading...

Loading...