System Manual Compact Systems 7 Start-Up

HI 800 141 E Rev. 2.02 Page 63 of 110

To get additional options for programming fault reactions in the user program, assign global

variable to AO.Error Code and Module Error Code. Refer to the manual of the compact system

or module for more details.

7.3.5 Configure Line Control

The pulse delay for line control is the time between setting the pulsed outputs to FALSE and the

latest possible reading of the signal on the corresponding input.

The default value is set to 400 μs. This value might need be increased if longer wires are used.

The maximum value is 2000 μs.

The minimum time for reading all inputs results in

pulse delay x number of pulses.

The pulsed outputs are usually set to TRUE and change to FALSE in succession for the

duration of the pulse delay once per cycle.

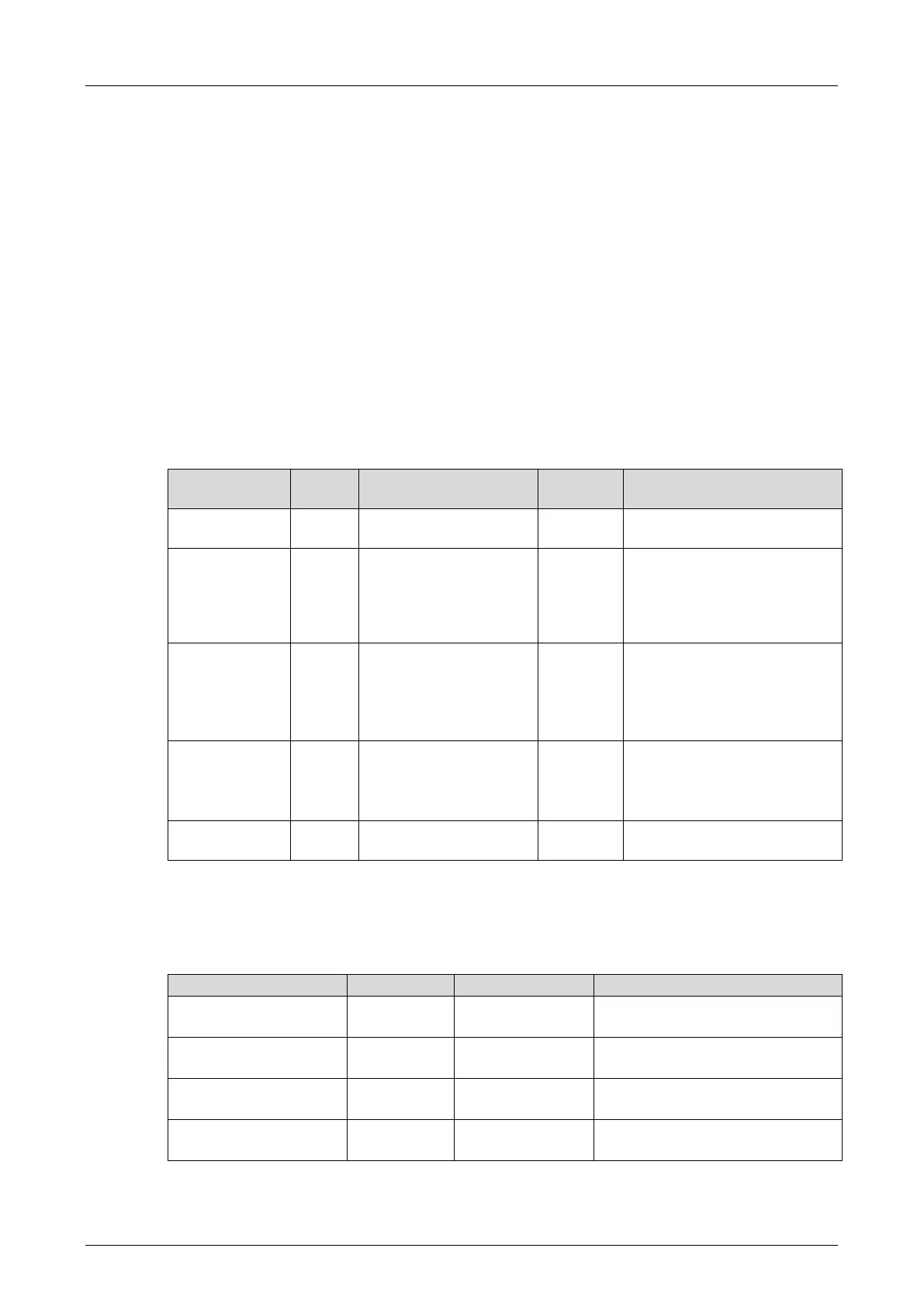

7.3.5.1 Required Variables

The following parameters must be created as global variables in the SILworX Global Variable

Editor:

Module slot with pulsed

outputs

With compact devices, the

DOs are used in slot 1, 2 or

3, see Table 37.

With the F60, the slot (3...8)

is given.

Value in µs

Maximum value: 2000 µs

F20: Pulse delay must be ≥

500 µs.

Refer to the F20 manual.

Pulse 1

Pulse 2

...

Pulse 8

Pulse 1...8, as required, must

match the number of pulsed

outputs.

Initialization value for

pulsed outputs

Activation of pulsed outputs

Table 35: Parameters for Line Control

The signal can be named freely; the names used in this manual are examples. All parameters

have the Const attribute.

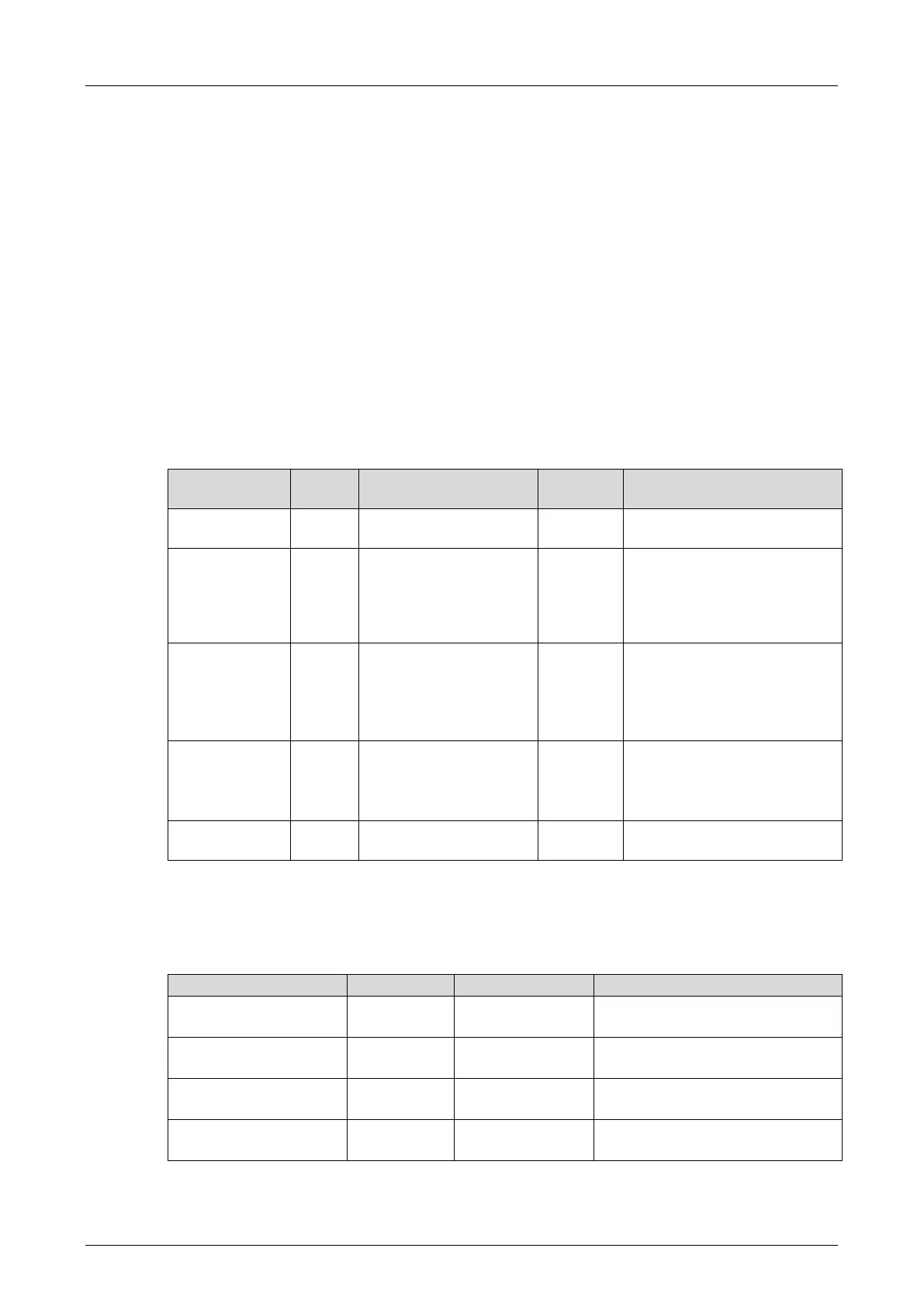

The following table specifies the switch variables used in the example:

First and second contact of

switch 1

First and second contact of

switch 2

FC_S1_1_pulsed

FC_S1_2_pulsed

Error codes for first and second

contact of switch 1

FC_S2_1_pulsed

FC_S2_2_pulsed

Error codes for first and second

contact of switch 2

Table 36: Switch Variables for Line Control

Loading...

Loading...