The "forward rotation direction" set by the factory is "counterclockwise rotation (CCW)" as viewed from the

load side of the servo motor.

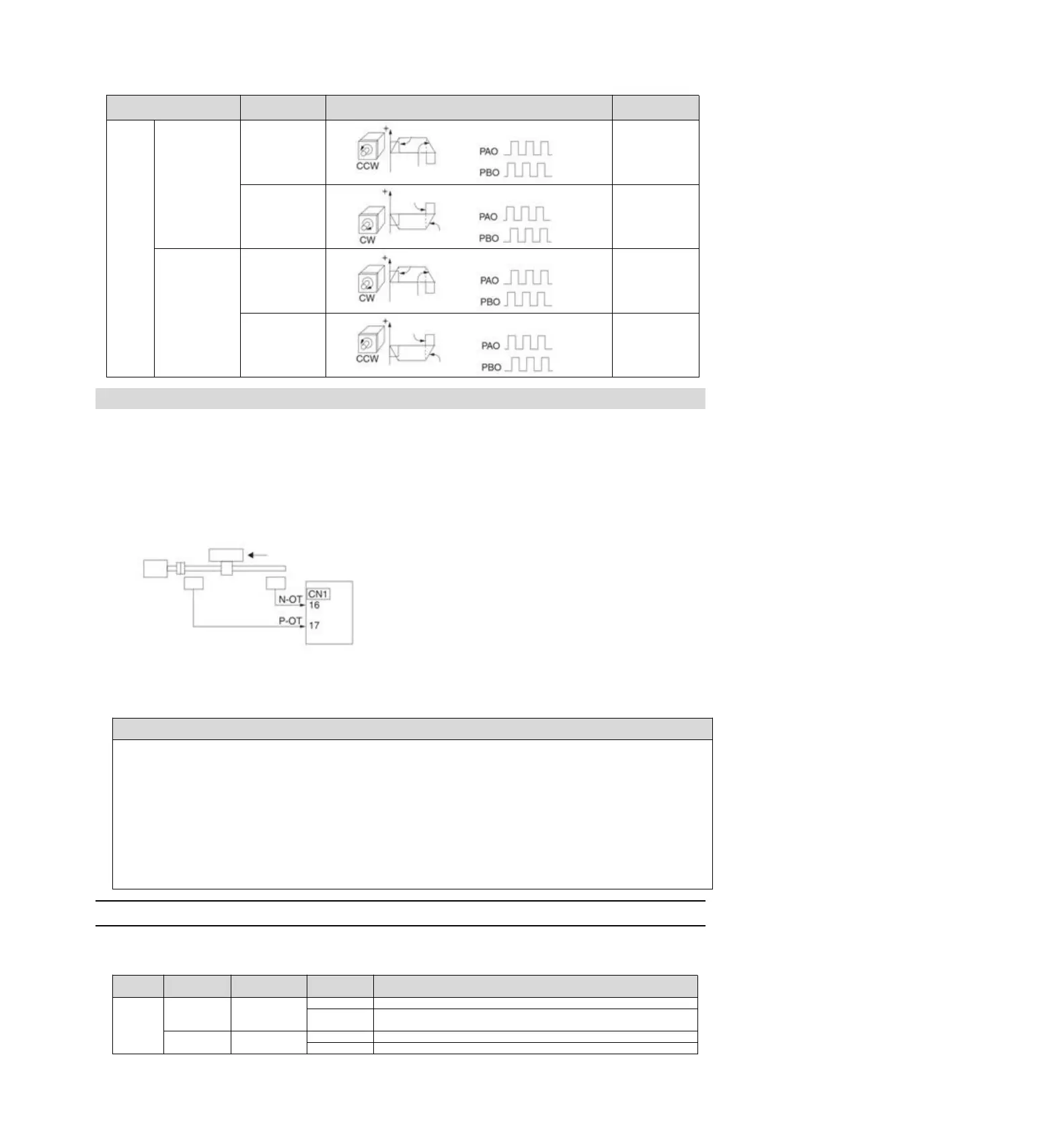

Motor rotation direction and encoder frequency division

pulse output

n. 0 the

CCW direction

is the forward

rotation

direction.

Factory

setting]

Prohibit

positive

rotation side

drive input

(P-OT) signal

Disable

reverse side

drive input

(N-OT) signal

n. 1 the

CW direction

is the forward

rotation

direction.

Reverse

Mode)

Prohibit

positive

rotation side

drive input

(P-OT) signal

Disable

reverse side

drive input

(N-OT) signal

5.8 Functions and settings of over-travel prevention

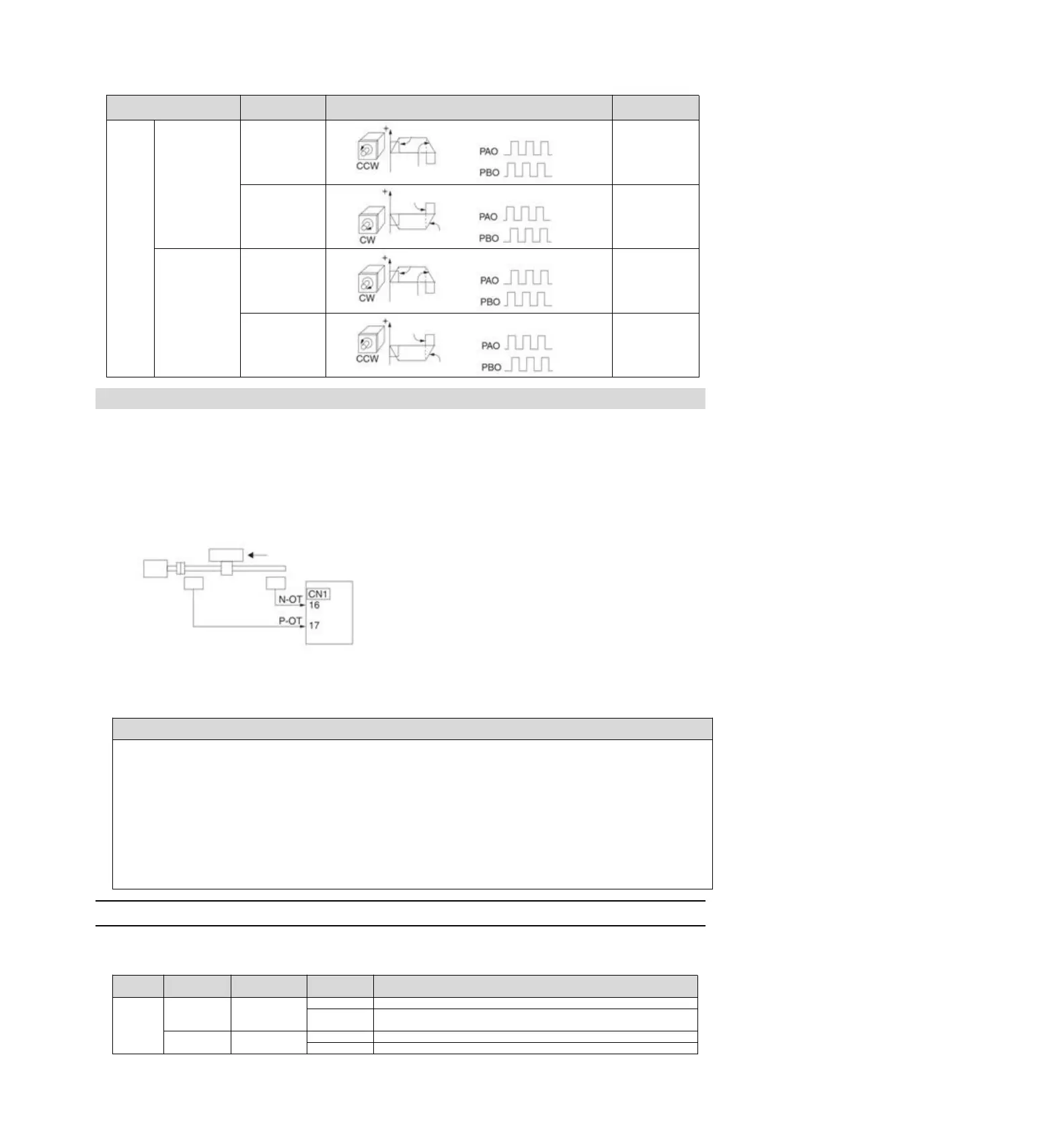

The over-travel prevention function of servo drive refers to the safety function of forcing the servo motor to

stop by inputting the signal of limit switch when the movable part of the machine exceeds the designed safe

movement range.

The overtravel signal includes a P-OT signal that prohibits forward rotation and an N-OT signal that prohibits

reverse rotation. The P-OT and N-OT signals are used to set a limit switch at the position to be limited when

starting the machine under the drive of the servo motor, and then stop the machine through the signals.

Examples of servo drive wiring are shown below.

Rotary applications such as round tables and conveyors do not require over-travel prevention function, and

there is no need to wire the over-travel prevention input signal at this time. The following is a description of the

parameter setting related to the over-travel prevention function.

In order to prevent accidents caused by poor contact and disconnection of contact parts, please use "normally closed

contact" for limit switches.

In addition, do not change the factory setting of the polarity of over-travel signals (P-OT, N-OT).

When the servo motor is used as a vertical shaft, the brake control output (/BK) signal will remain in the ON (brake

on) state in the overtravel state, so the workpiece may fall off when overtravel occurs. In order to prevent the

workpiece from falling off, please set it to a zero fixed state after the servo motor stops (Pn 001 = n.1).

In case of overtravel, it will enter the base blocking state after stopping, but it may be dragged back when the load

shaft side receives external force. In order to prevent the servo motor from being dragged back due to external force,

please set it to a fixed zero position after the servo motor stops (Pn 001 = n.1).

5.8.1 Overtravel signal

The overtravel signal includes a P-OT signal that prohibits forward rotation and an N-OT signal that prohibits

reverse rotation.

Forward-turning side can be driven (normal operation)

It is forbidden to drive the forward rotation side (forward rotation

side over travel)

The reverse side can be driven (normally operated)

Reverse side drive is prohibited (reverse side overtravel)

Encoder frequency division

pulse output

Encoder frequency division

pulse output

Encoder frequency division

pulse output

Encoder frequency division

pulse output

Motor forward rotation direction

Loading...

Loading...