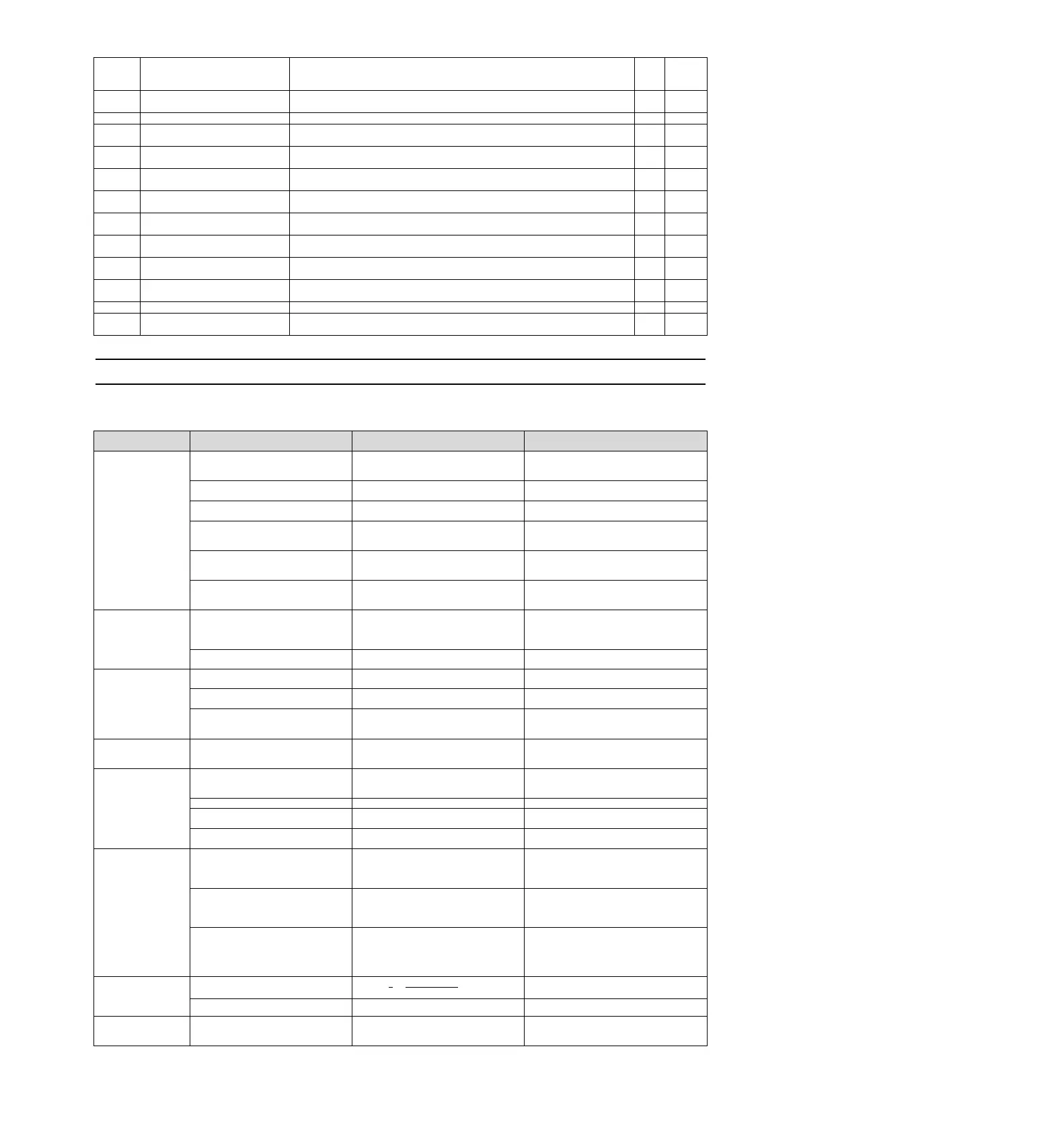

deviation caused by speed limit when

servo is on

executed by the speed limit value (Pn529 or Pn584) when the servo is ON. When a

position command is input in this state, the limit is not released and the set value of the

warning value (Pn520) for excessive position deviation is exceeded.

Excessive deviation between motor

and load positions

In full closed loop control, the deviation between motor and load position is too large.

Location data is too large

The position feedback data exceeds 1879048192.

MECHATROLINK Internal

Synchronization Exception 1

MECHATROLINK communication and servo drive synchronization are abnormal.

MECHATROLINK transmission cycle

setting error

The transmission period of MECHATROLINK communication is set incorrectly.

The address setting of

MECHATROLINK station is abnormal

The address of MECHATROLINK Station is set incorrectly.

MECHATROLINK synchronization

exception

Synchronization exception occurred in MECHATROLINK communication.

MECHATROLINK synchronization

failed

Synchronization failure occurred in MECHATROLINK communication.

MECHATROLINK communication

failure (receiving error)

MECHATROLINK Communication failure occurs continuously during communication.

MECHATROLINK transmission cycle

is abnormal

Abnormal transmission period occurred in MECHATROLINK communication.

MECHATROLINK did not receive

synchronization frames

Unreceived synchronization frames occur continuously in MECHATROLINK

communication.

Command execution timed out

MECHATROLINK command timeout error occurred.

When the main loop power supply is ON, the low voltage state of one of the three phases

lasts for more than 1 second.

* This Alarm will not be saved in the Alarm record. Only on the panel display.

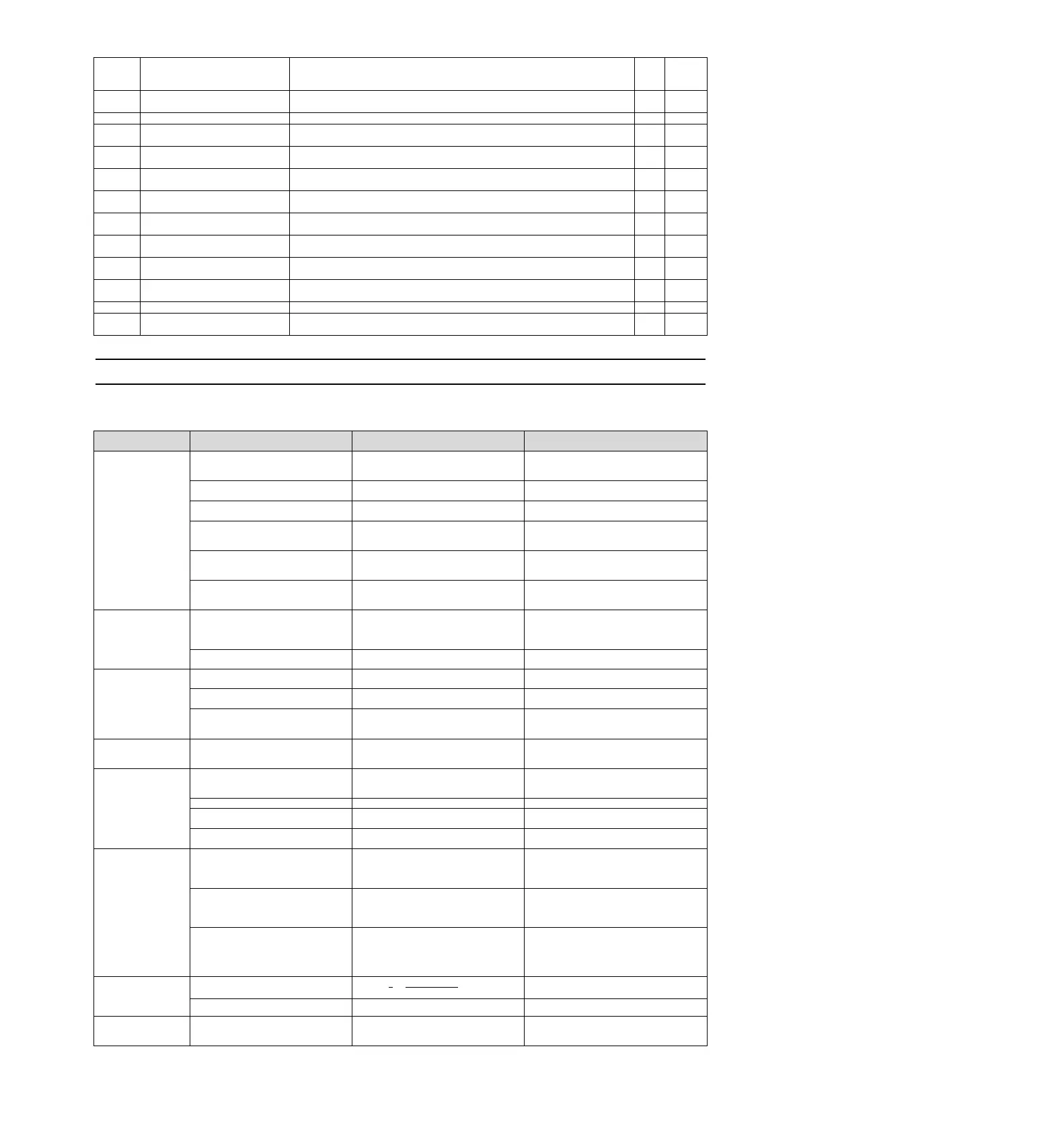

9.2.2 Cause of Alarm and Treatment Measures

The following table lists the cause of the alarm and the treatment measures. If the fault cannot be cleared after

processing according to the following table, please contact our agency or the nearest branch.

A.020:

Parameter and check

exceptions

The data of internal

parameters of servo

drive is abnormal.

The supply voltage drops

instantaneously.

Measure the supply voltage.

Set the power supply voltage within the

specification range, and perform initialization

of the parameter setting value.

Power off when writing parameters

Confirm the time of power failure.

Re-enter parameters after initialization of

parameter settings.

The number of writes to the parameter

exceeded the maximum

Confirm whether parameter changes are

frequently made from the upper device.

Replace the servo drive. Change the

parameter writing method.

Misoperation occurs due to interference

from AC power supply, grounding, static

electricity, etc.

Connect to the servo drive power supply

again. When the alarm still occurs, it may

be disturbed.

Take measures to prevent mutual interference.

Due to gas, water droplets or cutting oil,

etc., the components inside the servo

drive have failed.

Confirm the setting environment.

Connect to the servo drive power supply

again. When the alarm still occurs, it may

be a fault.

A.021:

Parameter format

exception

(The data of internal

parameters of servo

drive is abnormal.)

The software version of the write

parameter is updated as compared to

the software version of the servo drive

where the alarm occurred.

Read the product information and confirm

whether the software versions are the

same. If the versions are different, an alarm

may occur.

Write the parameters of other servo drives

with the same software version and model,

and then switch on the power supply.

A.022:

System parameters and

check exceptions

(The data of internal

parameters of servo

drive is abnormal)

The supply voltage drops

instantaneously.

Measure the power supply voltage

The power supply was turned off in the

process of setting the auxiliary function.

Confirm the time of power failure.

Connect to the servo drive power supply

again. When the alarm still occurs, it may

be a fault.

A.030:

Main circuit detection

unit failure

A.040:

Parameter setting

exception

(beyond the set range)

Servo capacity does not match servo

motor capacity

Confirm the capacity of servo drive and

servo motor

Quantity and combination.

Capacity of servo drive and servo motor

Match each other.

Outside the parameter setting range

Confirm the setting range of the changed

parameters.

Set the changed parameters to values within

the set range.

The electronic gear ratio setting value is

outside the set range

Verify that the electronic gear ratio is

0.001<(Pn20E/Pn210)< 64000.

Set the electronic gear ratio to

0.001< (Pn20E/Pn210) < 64000.

A.042:

Parameter combination

exception

Since the electronic gear ratio (Pn20E

/Pn210) or servo motor is changed, the

running speed of the program JOG does

not conform to the set range.

Confirm whether the detection condition

formula

*1

is true.

Reduce the value of the electronic gear ratio

(Pn20E/Pn210).

Since the program JOG moving speed

(Pn533) has been changed, the running

speed of the program JOG does not

conform to the set range.

Confirm whether the detection condition

formula

*1

is true.

Increase the value of Pn533.

Due to the change of electronic gear

ratio (Pn20E/Pn210) or servo motor, the

moving speed of advanced automatic

adjustment does not conform to the set

range.

Confirm whether the detection condition

formula

*2

is true.

Reduce the value of the electronic gear ratio

(Pn20E/Pn210).

A.050:

Combination error

(outside the combinable

motor capacity range)

Servo drive capacity does not match

servo motor capacity

Confirm

1

4

≤≤

Motorcapacity

Servodrivecapacity

4

Capacity of servo drive and servo motor

Match each other.

A.051:

The product does not

support Alarms

The motor parameter file is not written

into the encoder (only when serial

conversion unit is not used)

Verify that the motor parameter file is

written into the encoder.

Write the motor parameter file into the

encoder.

Loading...

Loading...