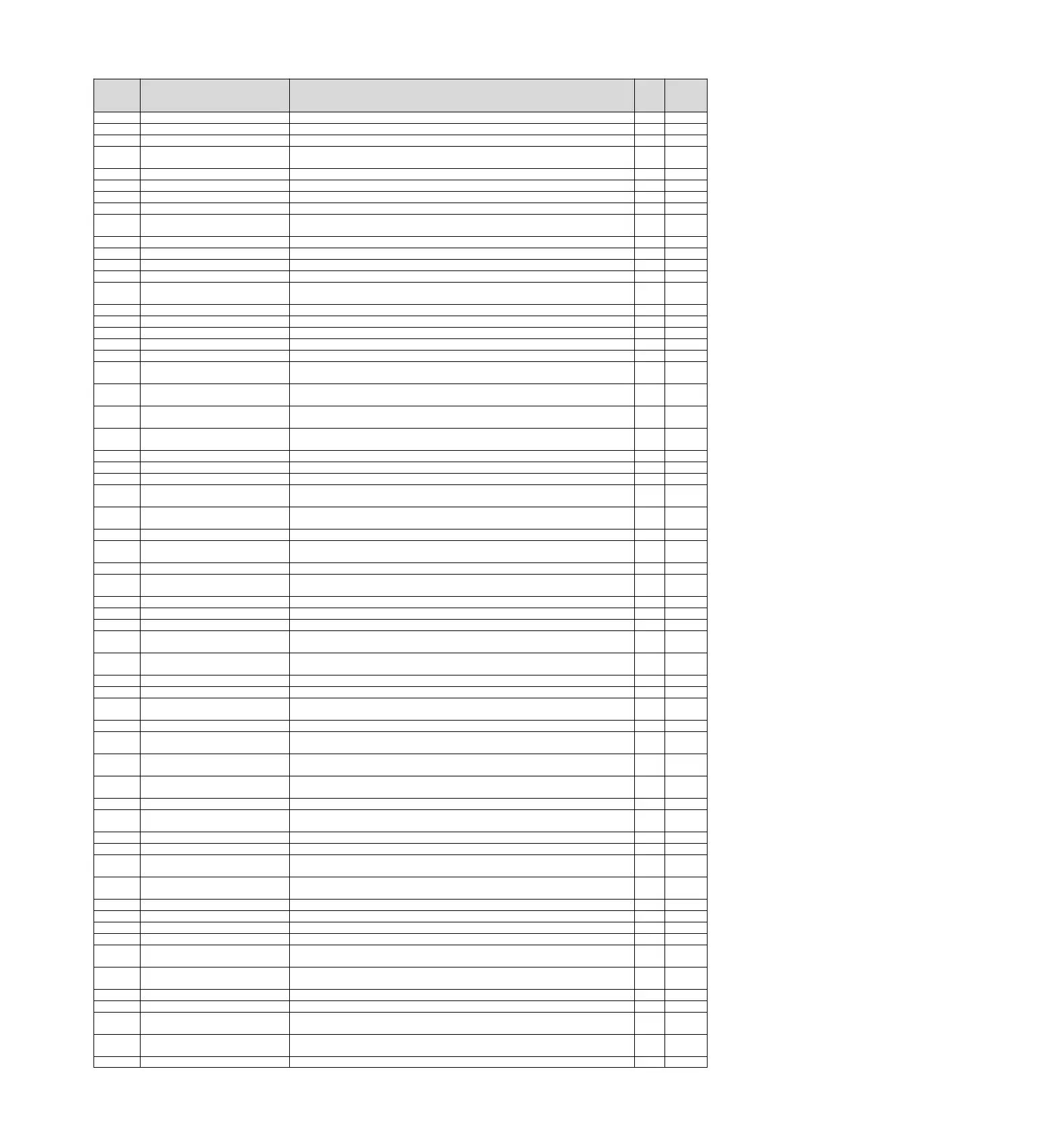

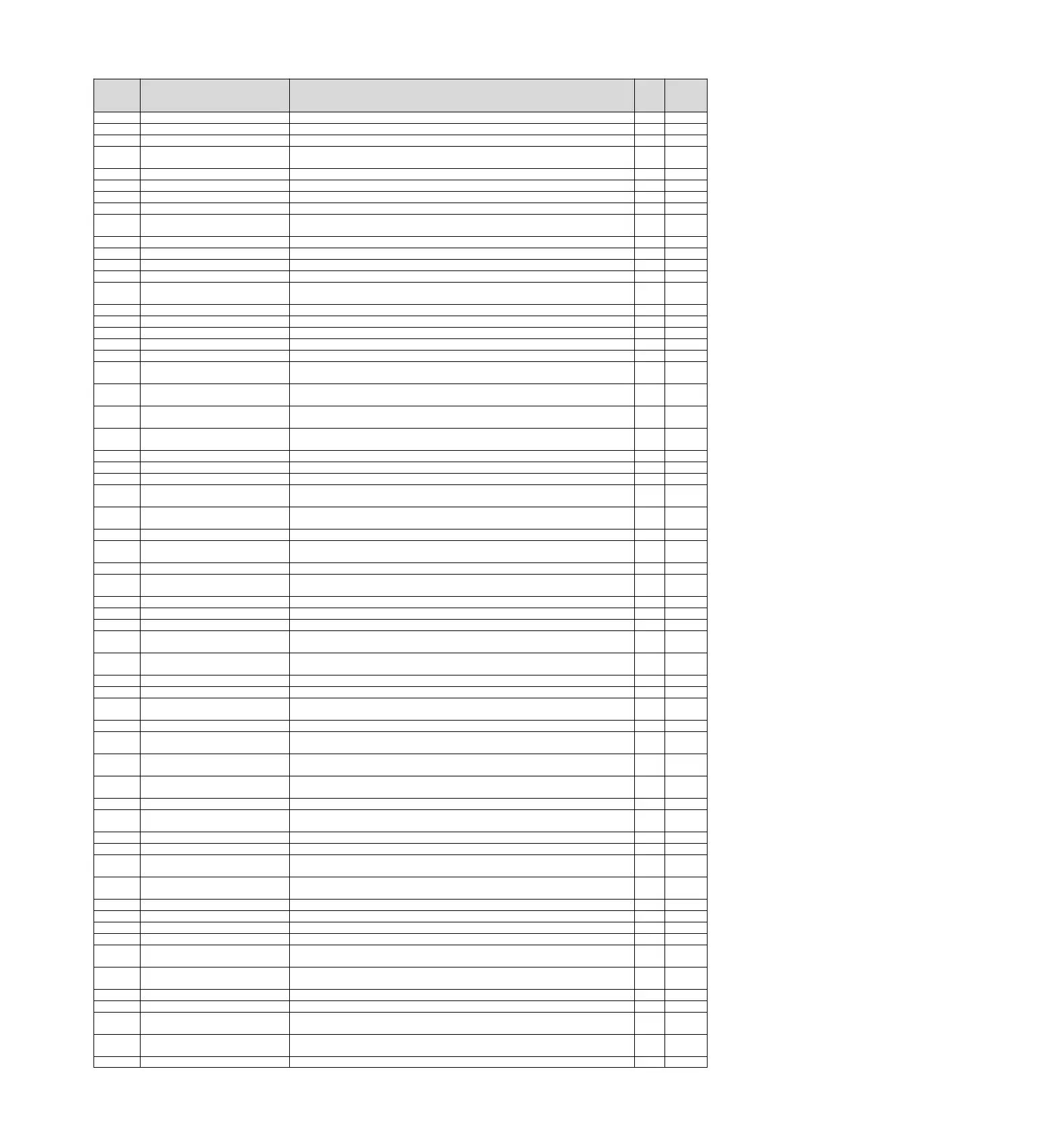

Alarm list

Parameter and check exceptions

The data of internal parameters of servo drive is abnormal.

Parameter format exception

The data format of internal parameters of servo drive is abnormal.

System and check exceptions

The data of internal parameters of servo drive is abnormal.

The main circuit detection unit is

abnormal.

Various detected data of the main circuit are abnormal.

Parameter setting exception

Parameter combination exception

The combination of multiple parameters is out of the set range.

Outside the combinable motor capacity range.

The product does not support Alarms

Unsupported products are connected.

Servo ON command invalid alarm

A servo ON command is sent from the upper device after performing the auxiliary

function of energizing the motor.

Power transistor overcurrent or heat sink overheating.

Motor overcurrent detection

A current exceeding the allowable current flows through the motor.

Regeneration overload occurred.

Main circuit power supply wiring error

The setting of AC power input/DC power input is incorrect. The power cord is wired

incorrectly.

The main circuit DC voltage is abnormally high.

The DC voltage of the main circuit is insufficient.

The motor speed exceeds the maximum speed.

Abnormal vibration of motor speed is detected.

Automatically adjust alarm

Vibration is detected in the automatic adjustment of the adjustment-free function.

Incorrect ESM requires exception

protection

A state transition request that cannot be converted from the current state was received.

Undefined ESM requires exception

protection

An undefined state transition request was received.

Boot state requires exception

protection

Bootstrap state transition request received.

PLL has not completed exception

protection

The phase combination of communication and servo is still unable to be completed after

synchronization is started for 1s.

PDO watchdog exception protection

When SP or OP, bit10 of ESC register 0200h is not ON within the specified time.

ESC hardware initialization error

ESC hardware initialization error.

ESM status is SP or OP, and the communication and servo phases do not match.

Abnormal protection of synchronous

signals

SYNC0 or IRQ interrupt processing timed out after synchronization processing was

completed.

The same period set abnormal

protection

Unsupported synchronization period (SYNC0) is set.

Mailbox Set Exception Protection

SM0/1 of mailbox is set incorrectly.

PDO Watchdog Sets Abnormal

Protection

PDO watchdog setting error.

DC set exception protection

SM event mode setting exception

protection

Unsupported SM events are set.

SM2/3 Set Abnormal Protection

SM2/3 is set to an incorrect value.

CAN controller hardware error

CAN transceiver hardware error

CANopen heartbeat timed out

Monitor heartbeat time loss or timeout

CANopen synchronization frame

timed out

Synchronization frame lost or timed out

TxPDO allocates exception

protection.

The data size of the TxPDO map exceeds 32 bytes.

RxPDO assigns exception protection.

The data size of the RxPDO map exceeds 32 bytes.

Lost link exception protection

After ESM leaves Init state, Port0 or 1 appears lost link state.

Overload (instantaneous maximum

load)

It runs for several seconds to tens of seconds with a torque greatly exceeding the rated

value.

Overload (continuous maximum load)

Continuous operation is carried out with torque exceeding the rated value.

Due to the action of DB (dynamic brake), the operating energy exceeds the capacity of

DB resistor.

Impulse current limiting resistor

overload

The main circuit power on frequency is too high.

The power supply of the encoder is completely exhausted and the position data is

cleared.

The sum check result of encoder memory is abnormal.

The voltage of the battery drops below the specified value after switching on the control

power supply.

Data inside encoder is abnormal.

When the power supply is ON, the encoder rotates at high speed.

MECHATROLINK communication

ASIC fault 1

MECHATROLINK Communication ASIC Failure 1 Occurred

MECHATROLINK communication

ASIC fault 2

MECHATROLINK Communication ASIC Failure 2 Occurred.

Servo motor out of control.

Phase information is inconsistent

Phase information is inconsistent.

Encoder communication failure

There is no communication between encoder and servo drive.

Abnormal acceleration of encoder

communication position data

A failure occurred in the calculation of encoder position data.

Encoder communication timer

exception

The communication timer between encoder and servo drive has failed.

Encoder parameter exception

Parameters of encoder are corrupted.

Encoder loopback check exception

The communication content with encoder is incorrect.

Position deviation is too large

In the servo ON state, the position deviation exceeds the excessive position deviation

warning value (Pn520).

Alarm for excessive position

deviation when servo ON

Servo ON is maintained when the position deviation in servo OFF exceeds the set value

of the excessive position deviation warning value (Pn526) when servo ON.

Alarm for excessive positi ON

When the servo is ON in the position deviation accumulation state, the speed limit is

Loading...

Loading...