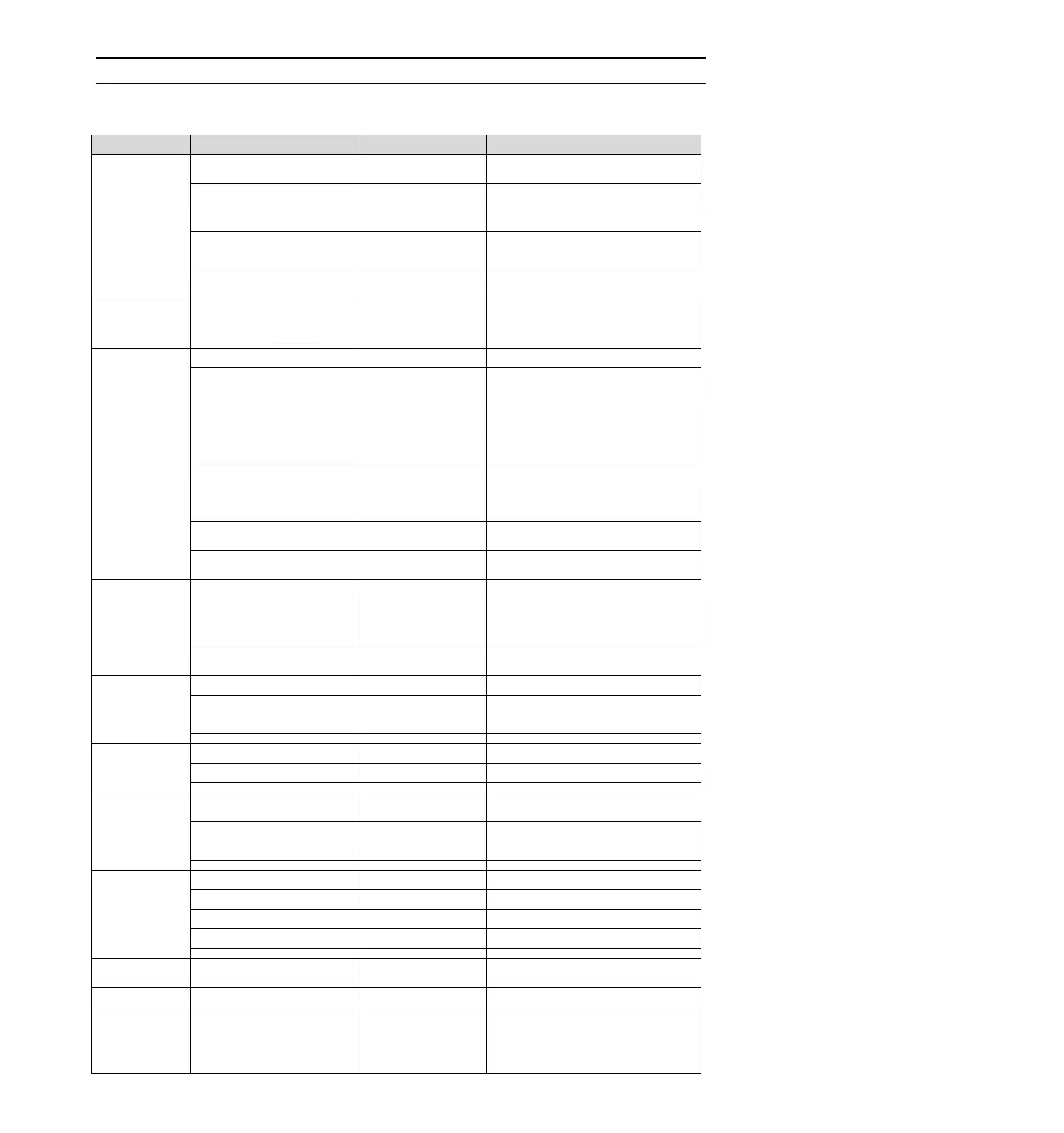

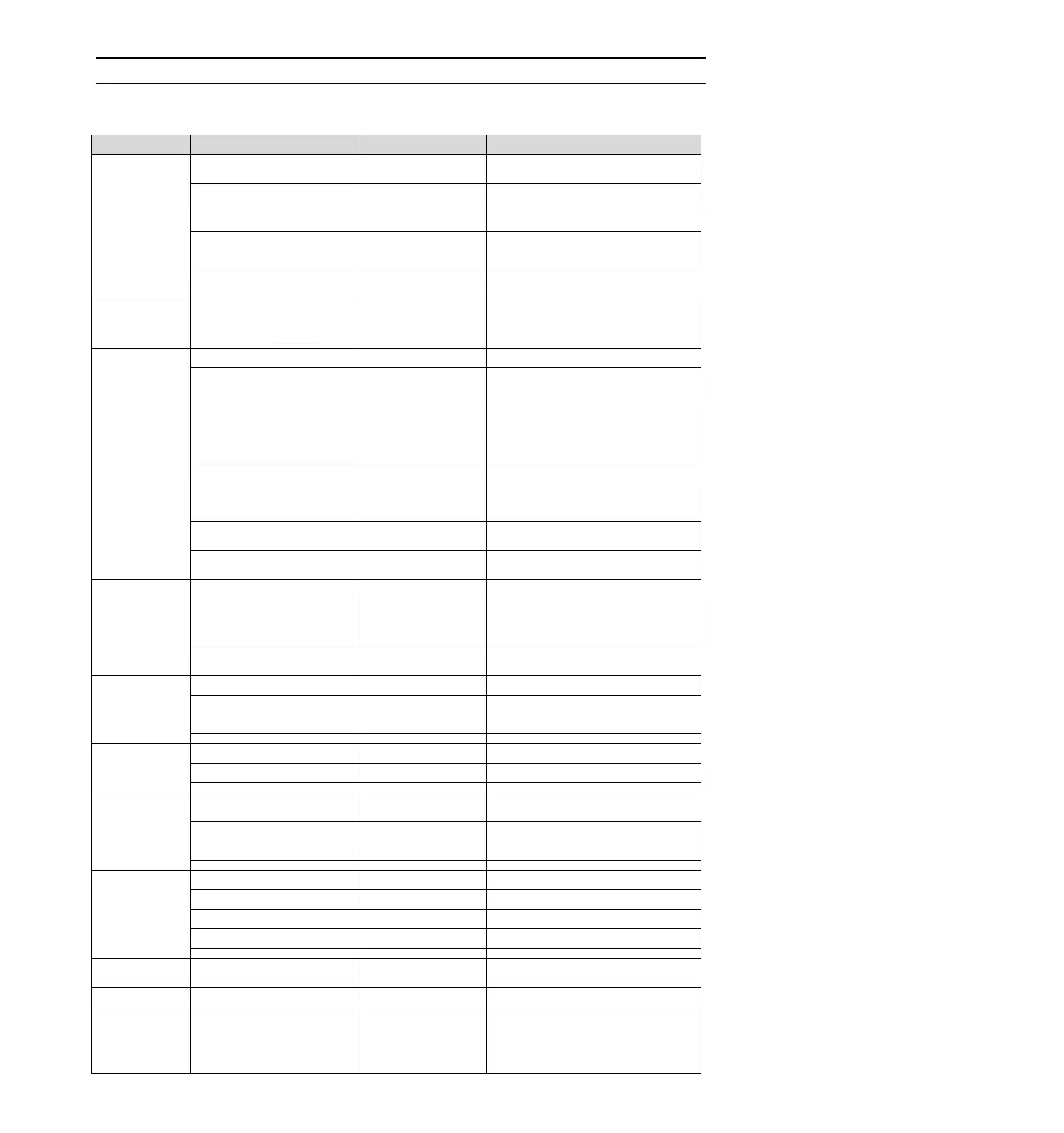

9.3.2 Reasons for Warning and Countermeasures

The following table lists the cause of the alarm and the treatment measures. If the fault cannot be cleared after

processing according to the following table, please contact our company.

A.900:

Position deviation is

too large

U, V, W wiring of servo motor is

incorrect

Confirm the connection of

servo motor main loop

cable.

Confirm whether the motor cable or encoder

cable has poor contact and other problems.

The gain of servo drive is low

Verify that the servo drive

gain is too low.

The servo gain is improved through automatic

adjustment (no-bit command) function, etc.

Position command acceleration is

too large

Try to reduce the

commanded acceleration

before running.

Lower the position command acceleration. Or,

select the position command filter to smooth

the acceleration of the position command.

Relative to the operating conditions,

the alarm (Pn520) for excessive

position deviation is low

Confirm that the position

deviation is too large for

warning value (Pn520) is

appropriate.

Correctly set the value of parameter Pn520

Connect to the servo drive power supply

again. When an alarm still occurs, replace the

servo drive.

A.901:

Excessive position

deviation when

servo ON

The accumulated position deviation

during servo ON exceeds the

proportion set by (

Pn526×Pn528

100

)

When the servo ON is correctly set, the

warning value of position deviation is too large

(Pn528).

A.910:

Overload

(Warning before

becoming overload

alarm (A.710 or

A.720))

Motor wiring, encoder wiring or poor

connection

Confirm whether there is any problem with

motor wiring and encoder wiring.

The operation of the motor exceeds

the overload protection

characteristic

Confirm the overload

characteristics and

operation commands of

the motor.

Discuss load conditions and operating

conditions again.

Or reconsider the motor capacity.

The motor is not driven due to

mechanical factors, resulting in

excessive load during operation

Confirm the operation

command and motor

speed.

Improve mechanical factors.

Verify that the overload warning

value (Pn52B) is appropriate

Verify that the overload

warning value (Pn52B) is

appropriate.

Verify that the overload warning value (Pn52B)

is appropriate.

Abnormal vibration in motor

operation is detected

Confirm the abnormal

sound of the motor and the

speed and torque

waveforms during

operation.

Reduce motor speed. Or reduce servo gain

through custom adjustment, etc.

The value of the moment of inertia

ratio (Pn103) is larger than the

actual value or varies greatly

Confirm the moment of

inertia ratio or mass ratio.

Correctly set the moment of inertia ratio

(Pn103).

Vibration detection value (Pn312 or

Pn384) is inappropriate

Verify that the vibration

detection value (Pn312 or

Pn384) is appropriate.

Set the vibration detection value (Pn312 or

Pn384) appropriately.

A.920:

Regeneration

overload

(Warning before

becoming

regeneration

overload (A.320))

Power supply voltage exceeds

specification range

Measure the supply

voltage.

Set the power supply voltage within the

specification

External regenerative resistance

value, servo drive capacity or

regenerative resistance capacity is

insufficient, or in a continuous

regenerative state

Reconfirm operating

conditions and capacity.

Change the regenerative resistance value,

regenerative resistance capacity or servo drive

capacity. Adjust the operating conditions

again.

Continuously bears negative load

and is in continuous regeneration

state

Confirm the load applied to

the running servo motor.

Discuss the system including servo,

mechanical and operating conditions again.

A.921:

DB overload

(Warning before DB

Overload (A.731))

The motor is being driven by

external force

Confirm operation status.

Do not drive the motor by external force.

The rotating or operating energy

when DB stops exceeds the

capacity of DB resistor

Confirm the usage

frequency of DB by DB

resistance power

consumption.

Try the following measures.

Reduce the command speed of servo motor.

Reduce the moment of inertia or mass.

Reduce the number of DB stops.

A.930:

Battery failure of

absolute encoder

The battery is not well connected

and not connected

Confirm battery

connection.

Connect the battery correctly.

The battery voltage is lower than

the preset value (2.7 V)

Measure the battery

voltage.

A.960:

MECHATROLINK

Communication

warning

The communication cable of

MECHATROLINK is incorrectly

wired

Confirm the connection

status.

Connect MECHATROLINK communication

cable properly.

MECHATROLINK received data

incorrectly due to mutual

interference

Confirm the setting

environment.

Take the following anti-interference measures.

• Adjust the wiring of communication cable and

FG to avoid interference.

• Install ferrite cores on communication cables.

AC power supply voltage driven by

servo is too low

Measure the supply

voltage.

Adjust the power supply voltage to the normal

range

Power supply voltage drops during

operation

Measure the supply

voltage.

Increase power supply capacity

Instantaneous power failure

occurred

Measure the supply

voltage.

If the instantaneous stop holding time (Pn509)

is changed, it is set to a smaller value.

Replace the servo drive and connect the

reactor before using the servo drive.

An unexecuted command was

received in the current layer

The command will be sent after the sending

condition is met.

Out-of-range values are set in the

command data

Set the value within the set range in the

command data.

A.9A0:

Overtravel

(Check out

over-travel status)

Overtravel detected in servo ON

The status of the

over-travel signal is

confirmed through input

signal monitoring.

If the over-travel signal cannot be confirmed

through input signal monitoring, the over-travel

may be detected instantaneously. Carry out

the following projects.

• Do not execute commands from the upper

device to the over-travel field.

• Confirm the wiring of over-travel signal.

Loading...

Loading...