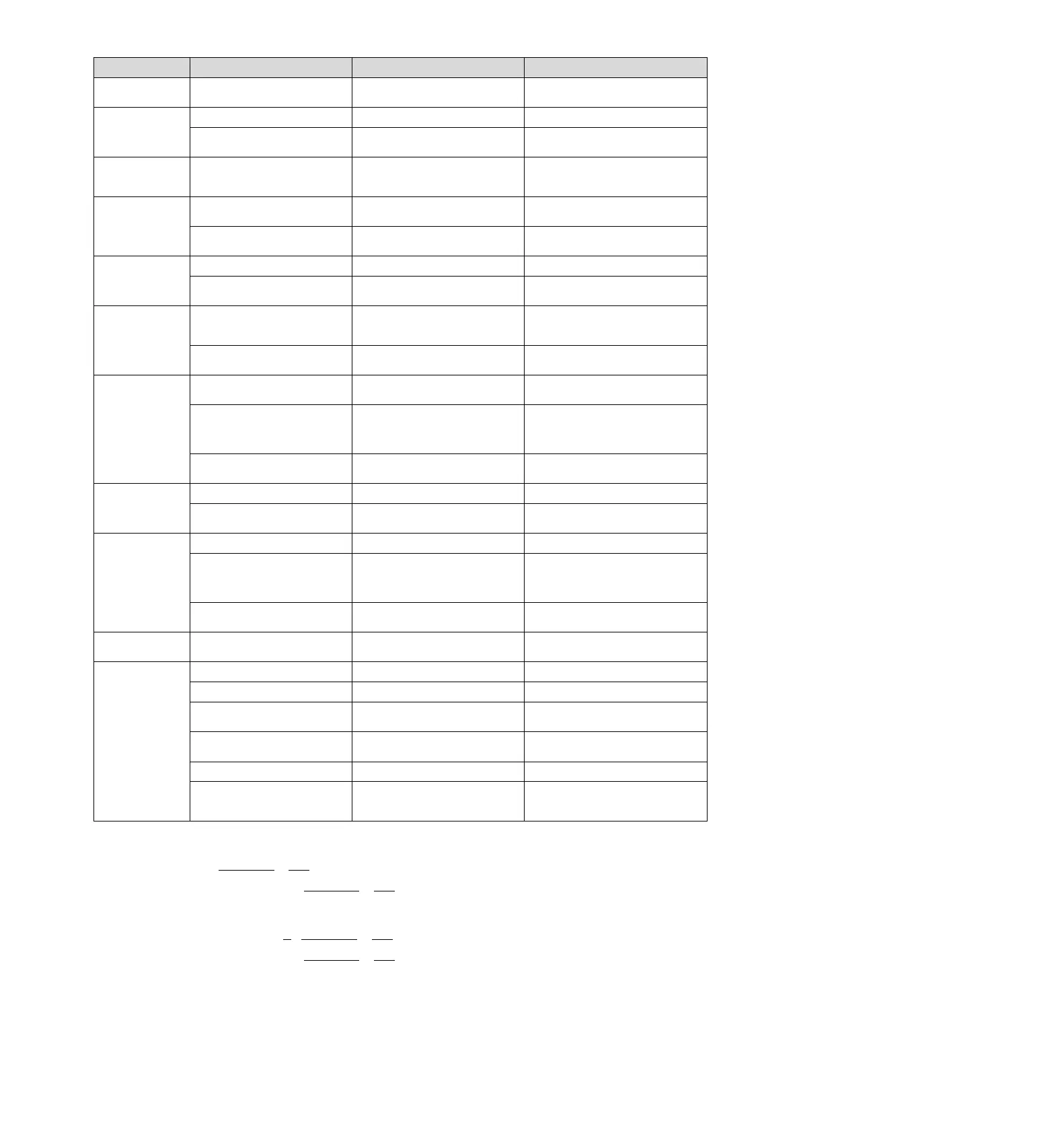

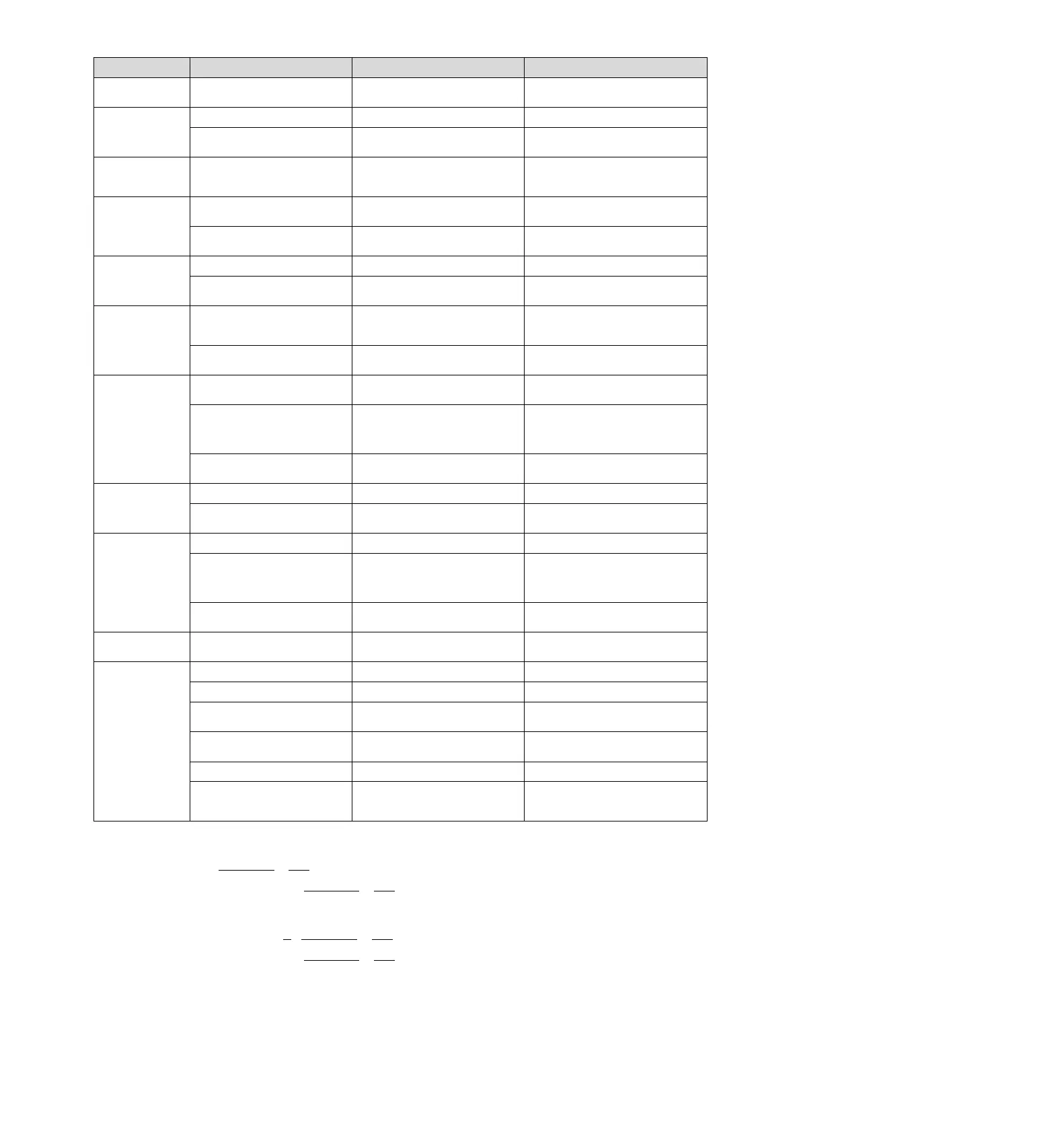

A.d30

Location data is too

large

Location data exceeds ±1879048192

Confirm the input command pulse counter.

Revise operating specifications.

A.E02:

MECHATROLINK

Internal synchronization

exception 1

The transmission period of

MECHATROLINK has changed

The reason for the transmission cycle

variation of the upper device is eliminated.

Connect to the servo drive power supply

again. When an alarm still occurs, replace the

servo drive.

A.E40:

MECHATROLINK

Transmission cycle

setting failure

MECHATROLINK transmission cycle

setting is out of specification range

Confirm the transmission cycle setting of

MECHATROLINK.

Set the transmission period of

MECHATROLINK to the correct value.

A.E42:

MECHATROLINK

Station address setting

exception

The station address is outside the set

range

Confirm whether the rotary switches (S1,

S2) are within the range of 03 ~ EF.

Confirm the station address setting of the

upper device and set the rotary switches (S1,

S2) to the correct values (03-EF).

The same address exists in the

communication network

Confirm whether the same address exists

in the communication network.

Confirm the station address setting of the

upper device and set the rotary switches (S1,

S2) to the correct values (03-EF).

A.E50*3:

MECHATROLINK

Synchronization

exception

WDT data update of upper device is

abnormal

Confirm WDT data update of the upper

device.

Correctly update WDT data of upper device.

Connect to the servo drive power supply

again. When an alarm still occurs, replace the

servo drive.

A.E51:

MECHATROLINK

Synchronization failed

When synchronous communication

starts, the WDT data of the upper device

is updated abnormally and synchronous

communication cannot be started

Confirm WDT data update of the upper

device.

Correctly update WDT data of upper device.

Connect to the servo drive power supply

again. When an alarm still occurs, replace the

servo drive.

A.E60*3:

MECHATROLINK

Abnormal of

communication

(Receiving error)

MECHATROLINK wiring is incorrect

Confirm the wiring of MECHATROLINK.

Connect MECHATROLINK communication

cable properly. Connect the termination

resistor correctly.

MECHATROLINK received data

incorrectly due to mutual interference.

Take measures to prevent mutual interference.

(Adjust the wiring of MECHATROLINK

communication cable or FG. E.g. adding

ferrite cores to the MECHATROLINK

communication cable, etc.)

Connect to the servo drive power supply

again. When an alarm still occurs, replace the

servo drive.

A.E61:

MECHATROLINK

Abnormal transmission

period (Synchronization

Interval Abnormal)

The transmission period of

MECHATROLINK has changed

Confirm the transmission cycle setting of

MECHATROLINK.

The reason for the transmission cycle

variation of the upper device is eliminated.

Connect to the servo drive power supply

again. When an alarm still occurs, replace the

servo drive.

A.E63:

MECHATROLINK

Synchronization frame

not received

MECHATROLINK wiring is incorrect

Confirm the wiring of MECHATROLINK.

Connect MECHATROLINK communication

cable properly.

MECHATROLINK received data

incorrectly due to mutual interference

Take measures to prevent mutual interference.

(Adjust the wiring of MECHATROLINK

communication cable or FG. E.g. adding

ferrite cores to the MECHATROLINK

communication cable, etc.)

Connect to the servo drive power supply

again. When an alarm still occurs, replace the

servo drive.

A.Ed1:

Command execution

timed out

MECHATROLINK command timeout

error occurred.

Confirm the monitor status when executing

the command.

Set to not execute SV_ON and SENS_ON

commands during motor operation.

A.F10:

Power cord phase loss

(When the main circuit

power supply is ON, the

low voltage state of one

of R, S and T phases

lasts for more than 1

second)

Poor connection of three-phase wires

Confirm the wiring of power supply.

Confirm whether there is any problem with the

power supply wiring.

Three-phase power supply imbalance

Measure the voltage of each phase of the

three-phase power supply.

Correct the imbalance of power supply

(change phase).

Single-phase AC power input (Pn00B =

n. 1 ) is not set and single-phase

power is input

Confirm power supply and parameter

settings.

Set correct power input and parameters.

Connect to the servo drive power supply

again. When an alarm still occurs, replace the

servo drive.

Poor connection or poor connection of

motor wiring

Confirm whether there is any problem with the

motor wiring.

Connect to the servo drive power supply

again. When an alarm still occurs, it is

possible that the servo unit has failed.

Replace the servo drive.

*1. Detection condition formula

When either of the following two conditional expressions holds, an alarm will be detected.

Pn533 [min

-1

] ×

Encoderresolution

6×10

5

≤

Pn20E

Pn210

Maximum speed of motor [min

-1

] ×

Encoderresolution

around3.66×10

12

≤

Pn20E

Pn210

*2. Detection condition formula

When either of the following two conditional expressions holds, an alarm will be detected.

Rated speed of motor [min

-1

] ×

1

3

×

Encoderresolution

6×10

5

≤

Pn20E

Pn210

Maximum speed of motor [min

-1

] ×

Encoderresolution

around3.66×10

12

≥

Pn20E

Pn210

Loading...

Loading...