Introduction

Modbus RTU RS232/RS485 Communication Ports

Revision 13 HC900 Process Controller Communications User Guide 5

April 2017

1.3 Modbus RTU RS232/RS485 Communication Ports

This implementation is designed to provide a popular data exchange format connecting the HC900 to both

Honeywell and foreign master devices via the RS232 and RS485 communication ports. The Modbus RTU allows the

instrument to be a citizen on a data link shared with other devices, which subscribe to the Modicon Modbus Protocol

Reference Guide PI-MBUS-300 Rev. G specification.

These instruments DO NOT emulate any MODICON type device. The Modbus RTU specification is respected in the

physical and data link layers. The message structure of the Modbus RTU function codes is employed and standard

IEEE 32-bit floating point and integer formats are used. Data register mapping is unique to the HC900 and other

Honeywell instruments. Section 6 describes the parameter mapping for the HC900.

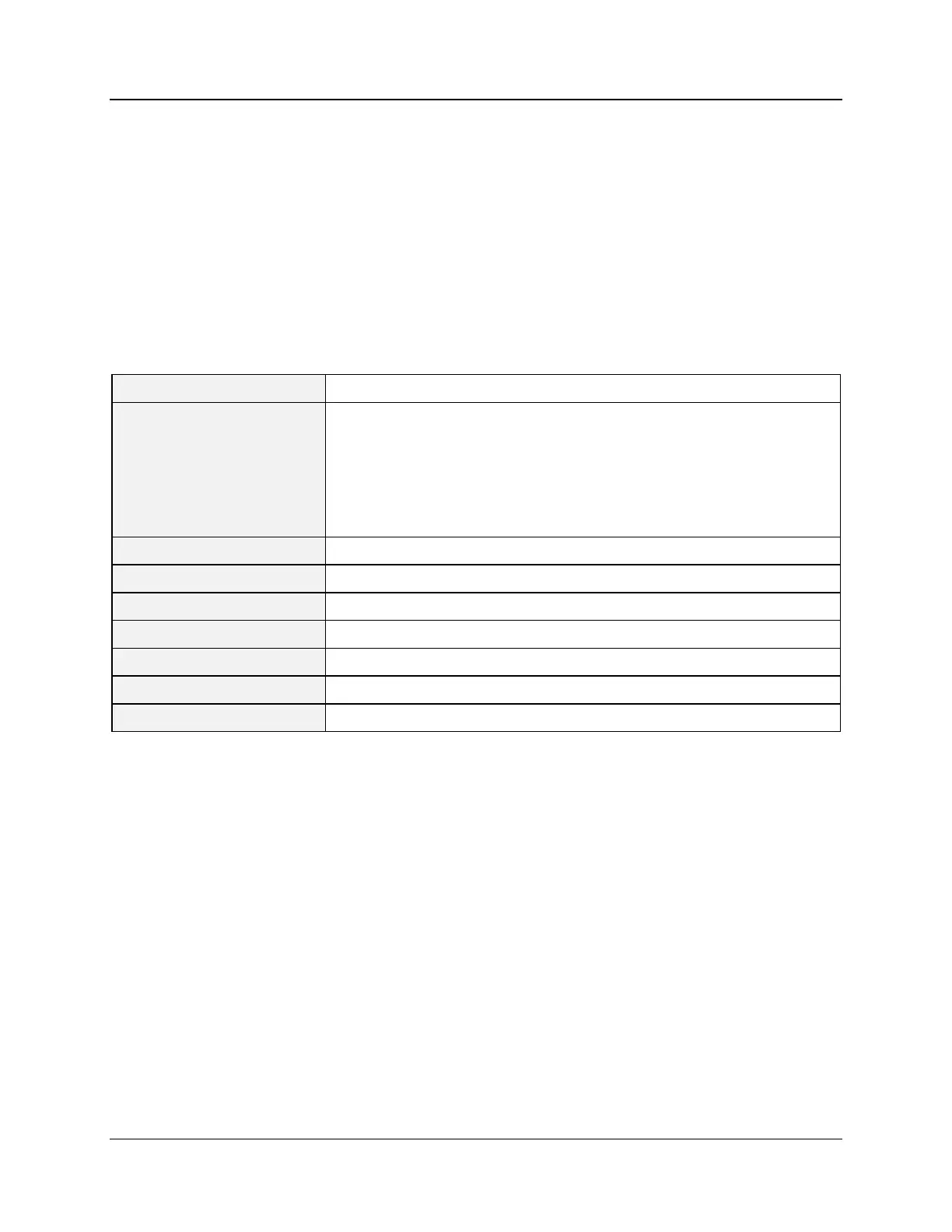

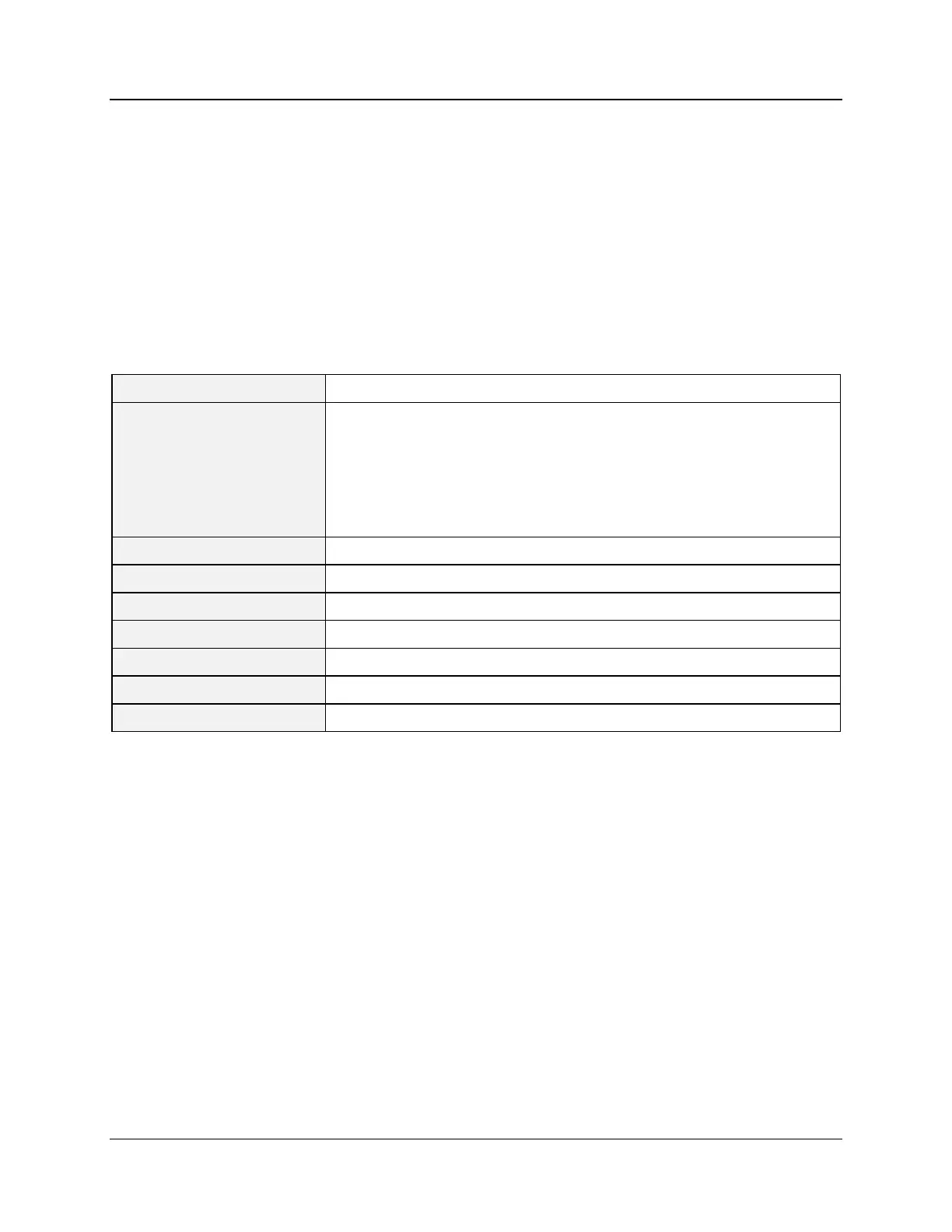

Modbus RTU Message Format

Table 1-1 Modbus RTU Message Formats

Number of data bits per

character

start bits - 1

data bits - 8

parity bits – 0 or 1 selectable

stop bits – 1 or 2 selectable

None, odd, even selectable

1200, 2400, 4800, 9600, 19200, 38400, 57600 Selectable

Half duplex Transceiver or TX/RX

CRC (cyclic redundancy check)

Idle line for 3.5 or more characters (>1.82 msec for 19200).

Modbus RTU Link Layer

The link layer includes the following properties/behaviors:

Slave address recognition,

Start / End of Frame detection,

CRC-16 generation / checking,

Transmit / receive message time-out,

Buffer overflow detection,

Framing error detection,

Idle line detection.

Errors detected by the physical layer in messages received by the slave are ignored and the physical layer

automatically restarts by initiating a new receive on the next idle line detection.

Loading...

Loading...