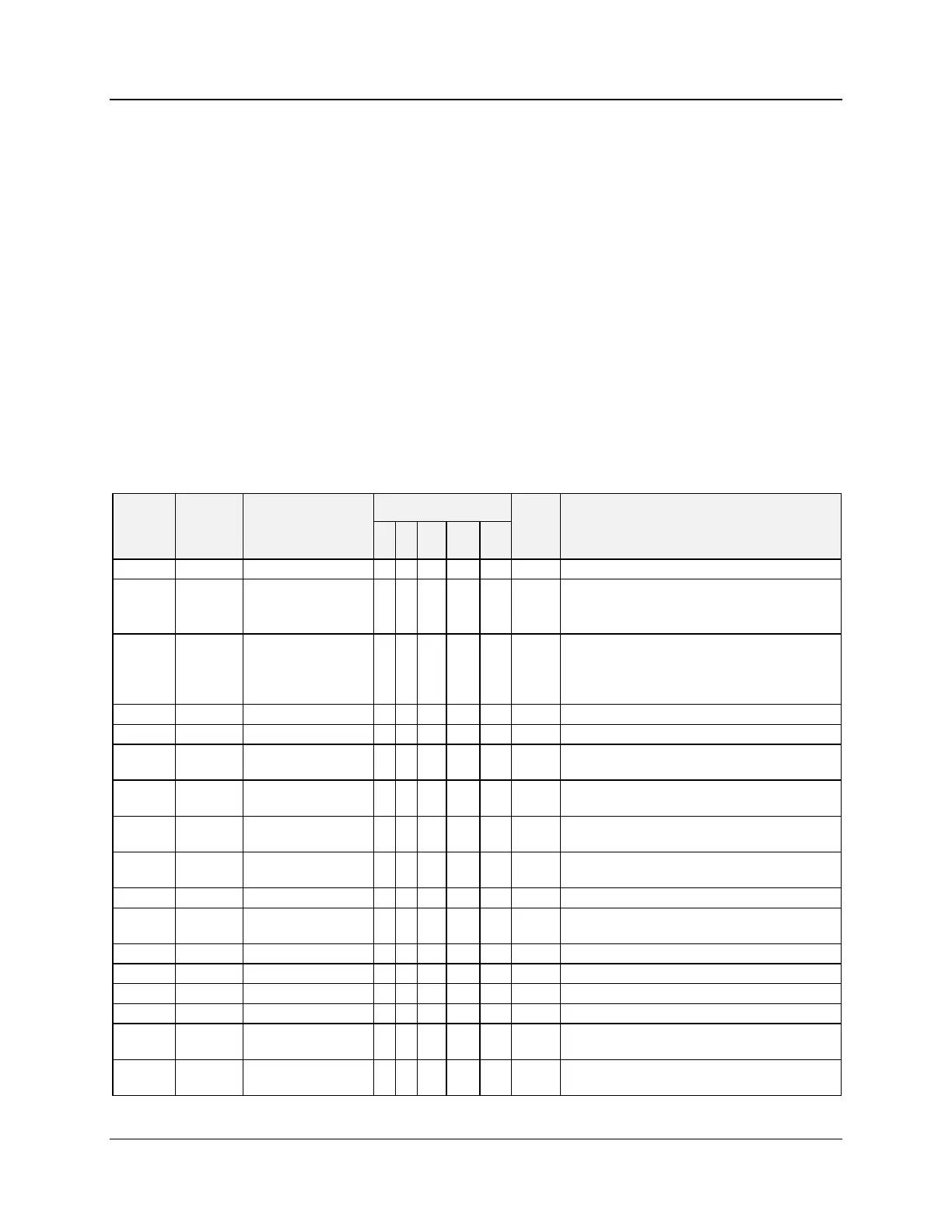

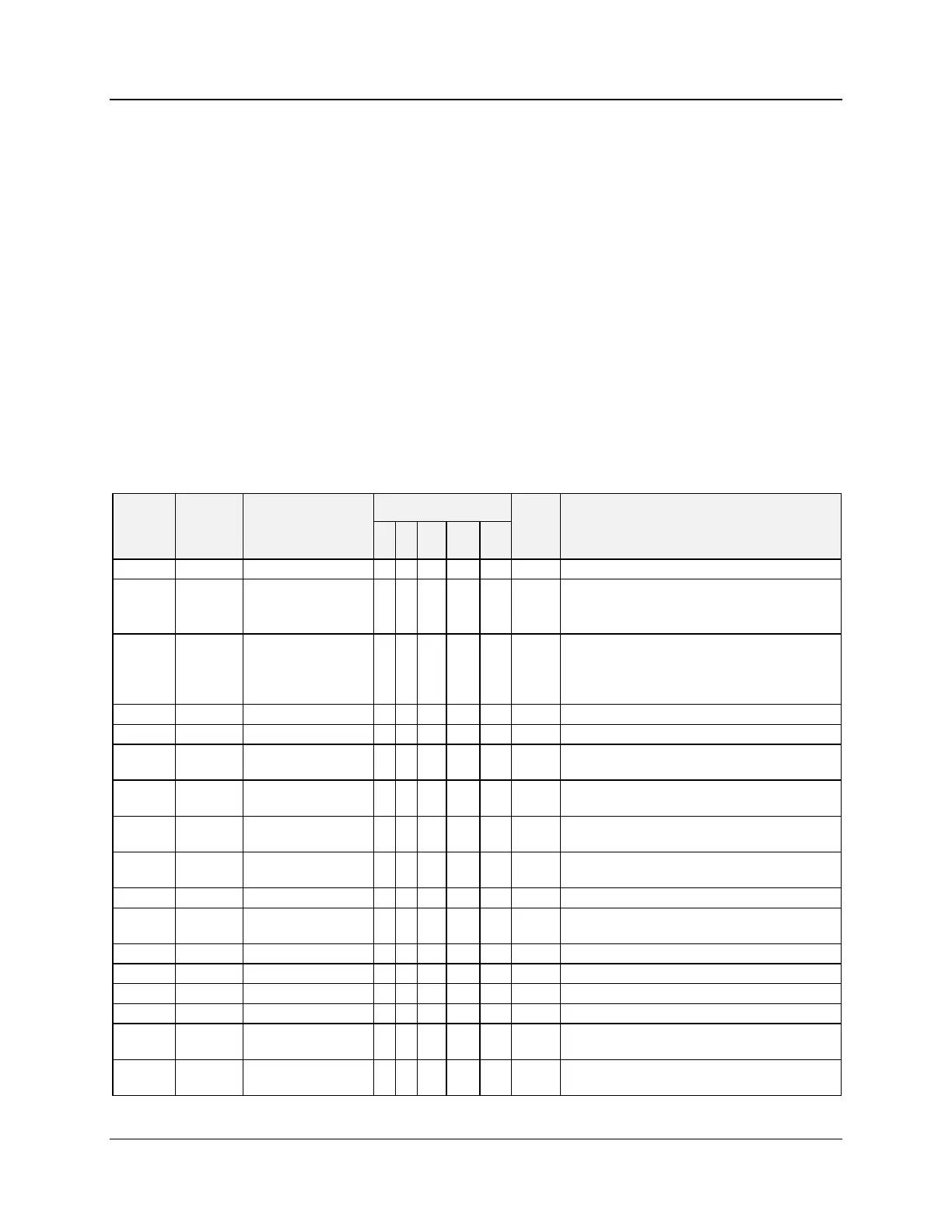

Parameters accessible with Function Code 03, 06,10h

Loop Values

Revision 13 HC900 Process Controller Communications User Guide 49

April 2017

6.4 Loop Values

About loop addresses

This table contains fixed addresses of Loop #1. See Table 6-1 for starting and ending fixed addresses

(hex) for Loop #2 through Loop #32. Each successive control loop is offset by 256 with the exception that

loop 25 has a new starting address and loop 26 – 32 are offset by 256. The loop number corresponds to the

PID block entry sequence during Process Control Designer configuration. The Modbus loop number

address for a loop can also be obtained from the Process Control Designer printout of Block Modbus

Addresses.

The addresses given in Table 6-3 do not necessarily apply to loops in the custom map. For custom

addresses view or print a report in HC Designer.

Function Code Support:

Reads – Function Code 3

Writes – Function Code 16 (10 hex) for preset of multiple registers (e.g., for floating point )

Writes – Function Code 6 for presetting an integer value

Table 6-3 Loop Values

Floating Point in Engineering Units.

Floating Point in Engineering Units.

When the remote setpoint source is configured as

LSP2, the value can be written.

Floating Point in Engineering Units.

On a write to this register the instrument will update

the proper set point according to the loop’s

currently selected set point.

Floating Point in Engineering Units.

Floating Point in Engineering Units.

Carbon Potential block

temperature

Floating Point in Engineering Units

Gain #1 (Prop Band

#1 if active)

Floating Point . (in units per what was configured in

the HC900: Gain or Proportional Band)

Floating Point

0.0=Direct; 1.0=Reverse

Floating Point in Repeats/Minute or

Minutes/Repeat.

Floating Point in Minutes

Cycle Time for Analog

Scan

Floating Point in Seconds

Floating Point in Engineering Units.

Floating Point in Engineering Units.

Floating Point in Engineering Units.

Floating Point in Engineering Units.

Gain #2 (Prop Band

#2 if active)

Three Position Step

Motor Deadband

Floating Point in percent

Loading...

Loading...