HSD

5801H0056 ______________________________________________________________ 111/181

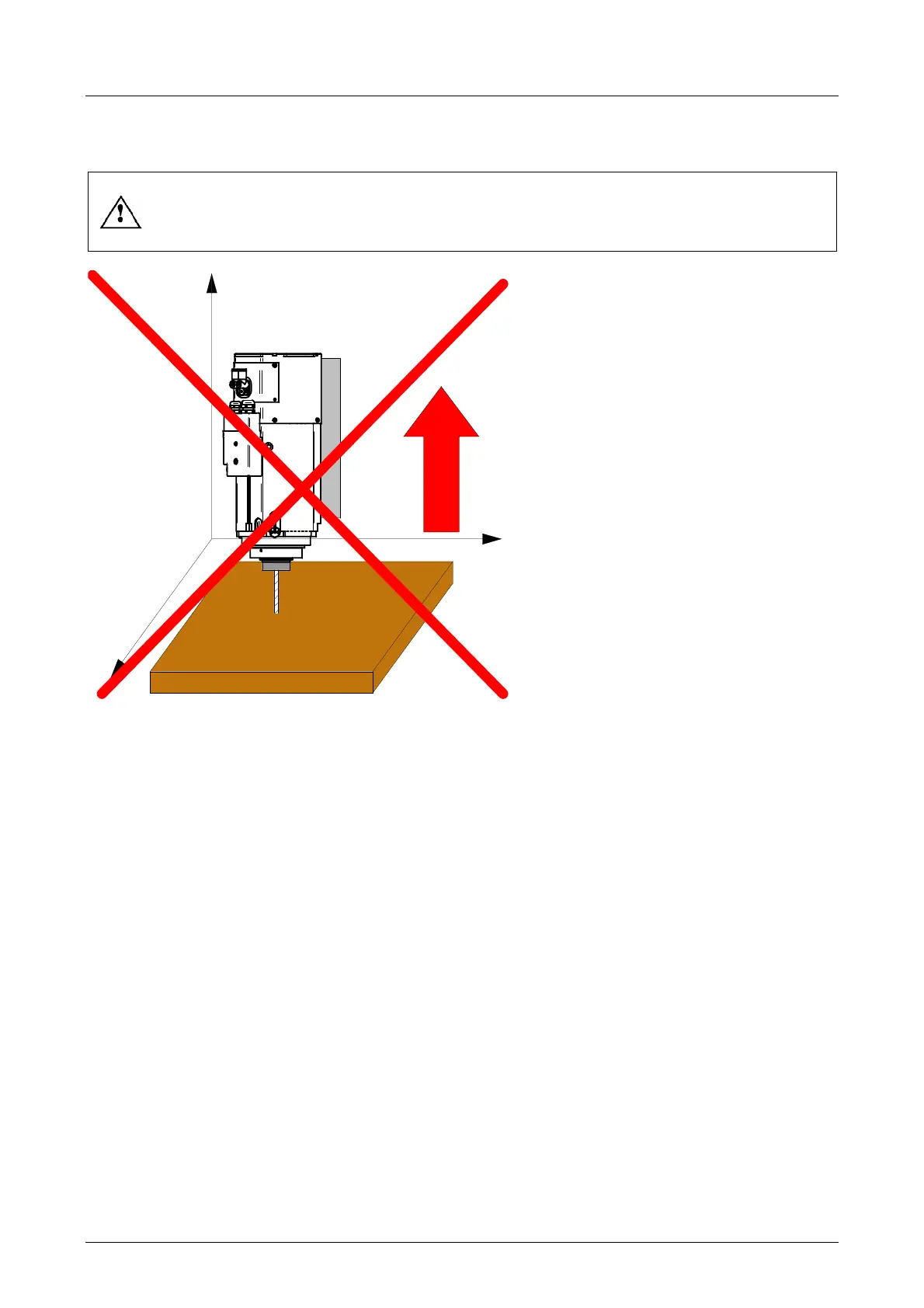

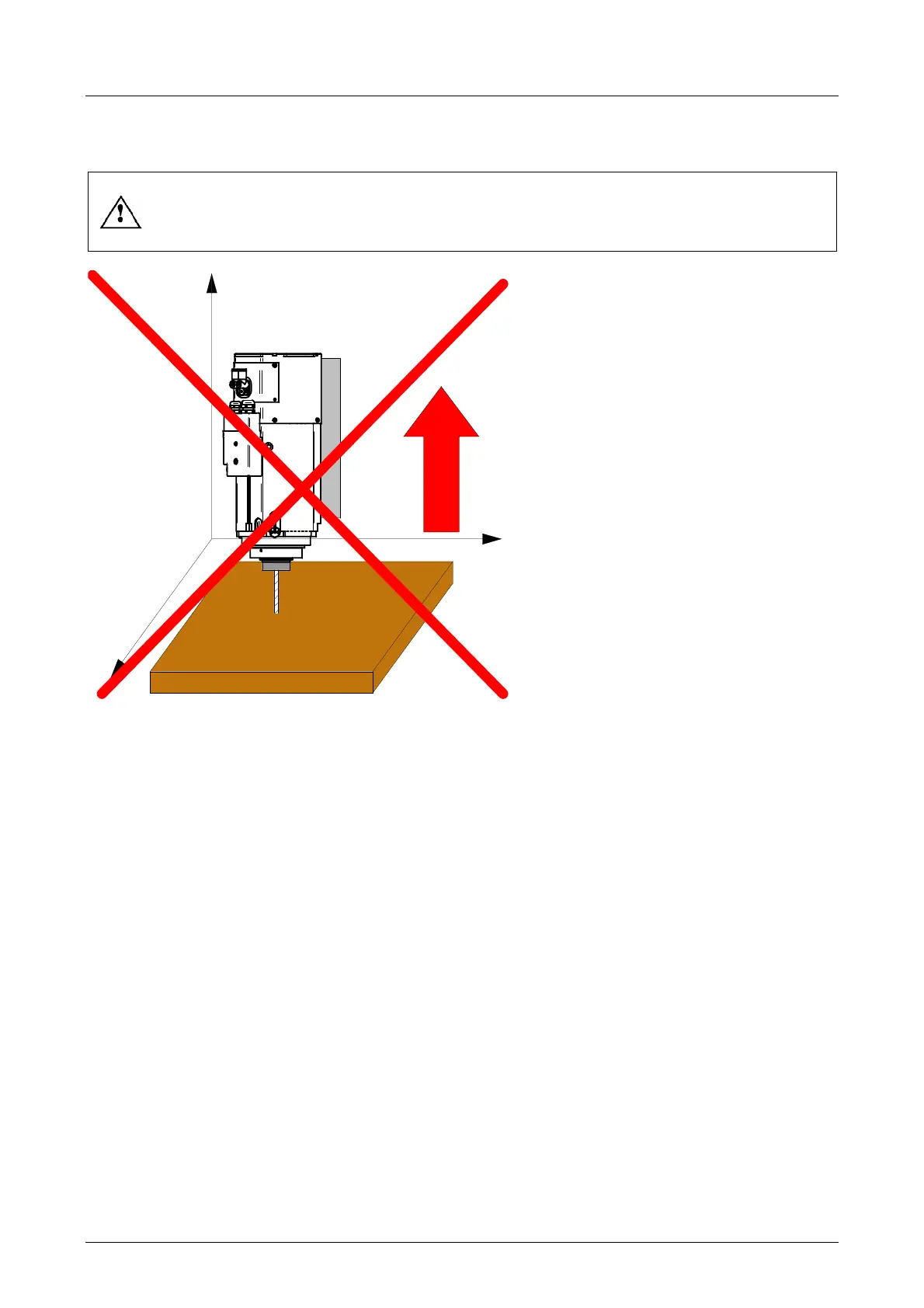

6.8 WHAT TO DO IF THE TOOL IS BLOCKED ON THE PIECE BEING

WORKED

In the models with an ISO type tool hook-up, if the machine goes into emergency mode

or stops with the tool blocked on the piece being worked, do not move the spindle along

the Z-axis!

Z

X

Y

If possible, release the piece manually and then carry out the tool changing manually.

If this is not possible, proceed in the following way:

• Supply air to the tool changing circuit

• Slowly move the spindle away from the piece, moving it along the Z-axis until the collet

opens (“ON” output of sensor S2)

• Check the collet spindle has been freed from the collet

• Move the spindle completely away from the piece being worked

• Remove the blocked tool manually.

Loading...

Loading...