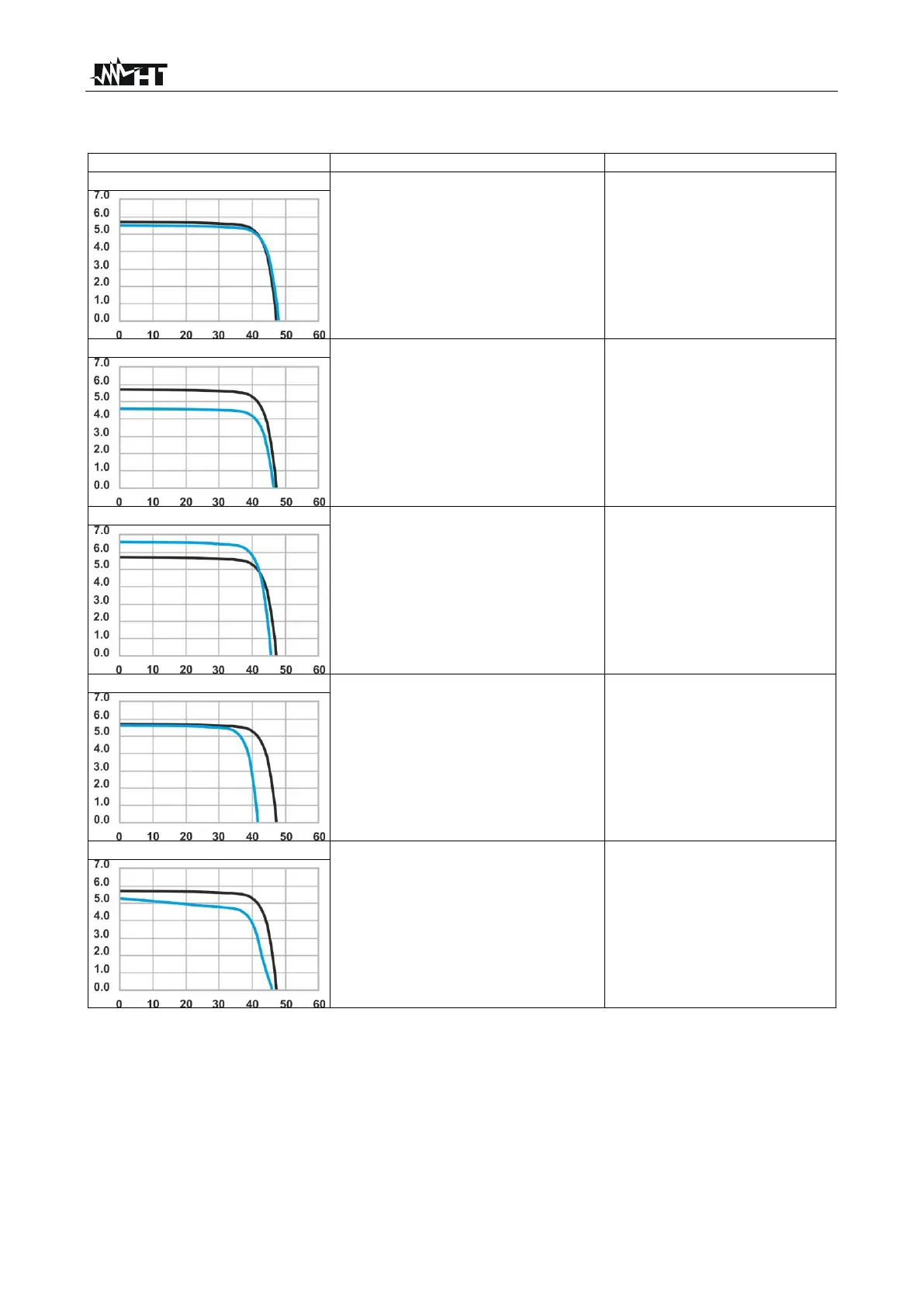

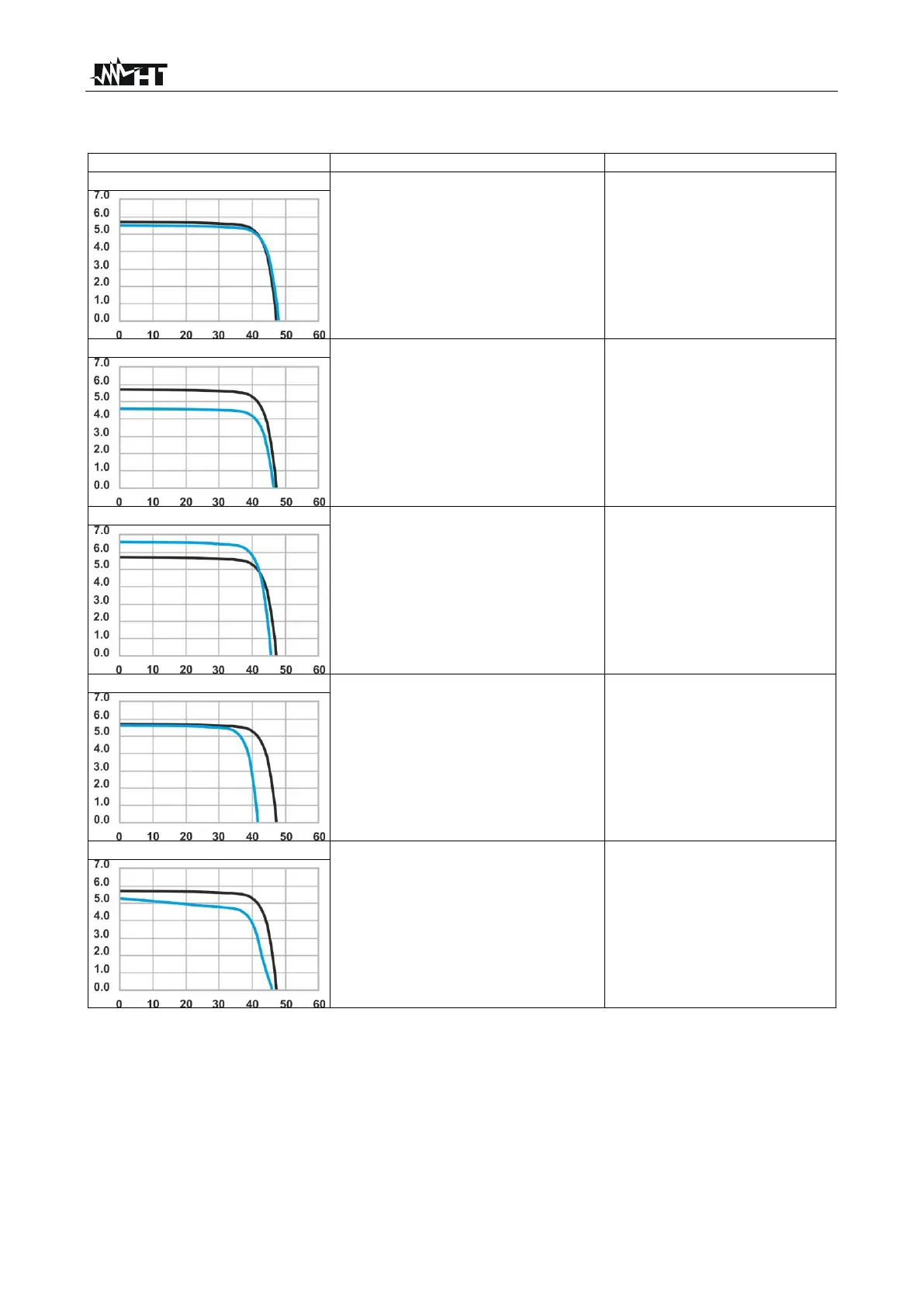

11.2. TYPICAL ERRORS ON I-V CURVES AND TROUBLESHOOTING

• The measured curve extrapolated

to STC (blue) and the curve as

declared by the manufacturer

(black) of the modules match.

• No error, save data and

move to next string to test

Low short circuit current

• Irradiance sensor oriented

differently than the string under test

• Reflections on the irradiance sensor

• Wrong module selection at

configuration of PV system

• Environmental contaminants on

modules (soiling, dirt, snow, debris)

• Far distance obstruction (shading)

• Aging

• Orient the irradiance sensor

properly

• Set the instrument properly

• Clean the modules

• Remove the obstructions

• Check the modules for

blindness, humidity, etc.

• Replace affected modules

High short circuit current

• Irradiance sensor oriented

differently than the string under test

• Reflections on the irradiance sensor

• Dirt on the irradiance sensor

• Wrong module selection at

configuration of PV system

• Irradiance sensor defect

• Orient the irradiance sensor

properly

• Clean the irradiance sensor

• Remove the obstructions

• Check the irradiance sensor

for blindness, humidity, etc.

• Set the instrument properly

• Replace affected sensor

• Low temperature measurement

• Wrong numbers of module

selection at configuration of PV

system

• Shorted bypass diodes

• Attach the thermocouple

properly to a typical

temperature location

• Select the AUTO mode

• Set the instrument properly

• Replace affected modules

Low current ratio Impp/Isc

• Soiling across modules

• Tapered shades

• Small current mismatch

• Degradation of cell shunt resistance

• Clean the modules

• Un-shade the modules

• Check that currents match

• Replace affected modules

Loading...

Loading...