OperatiOn

4-56 HPR800XD Auto Gas – 806500

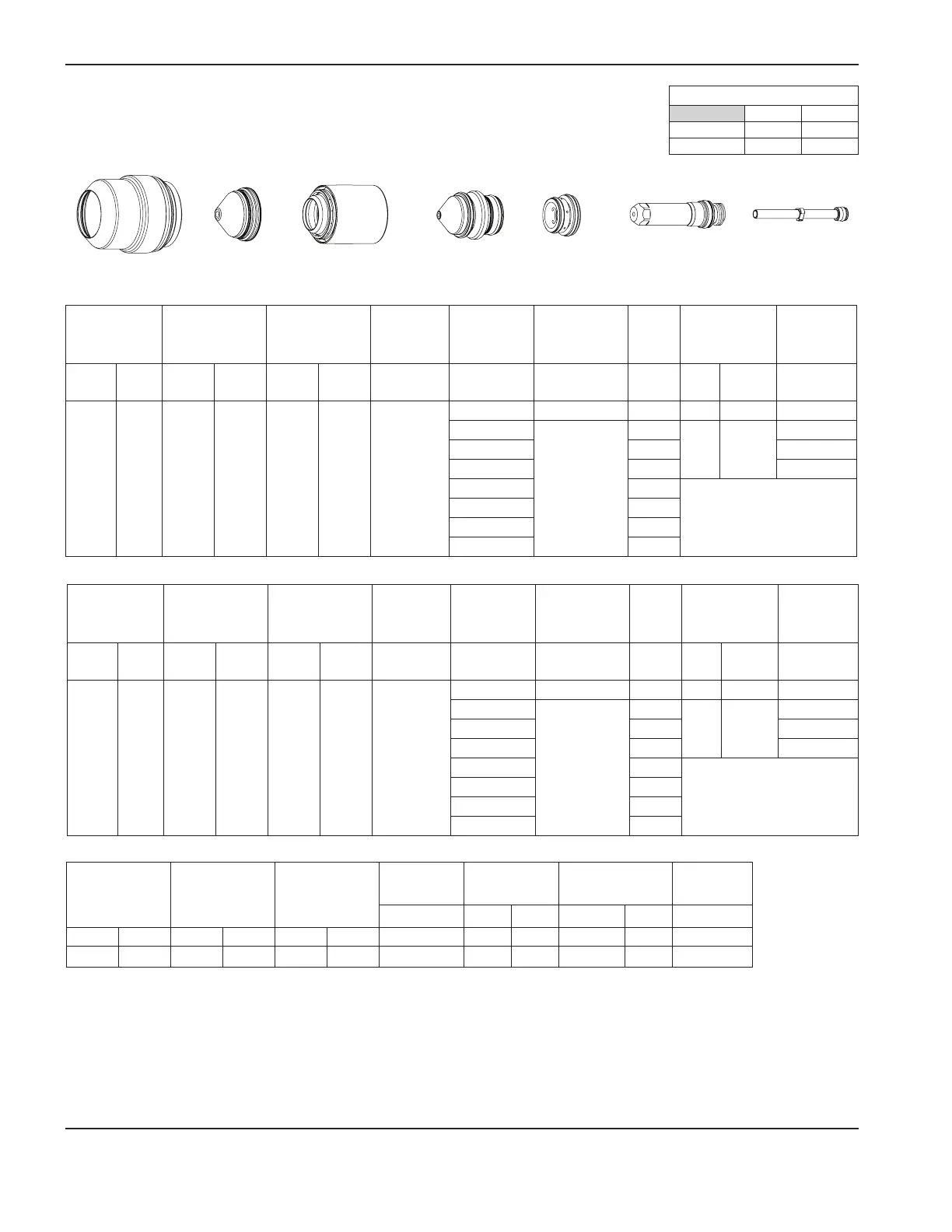

Select

Gases

Set

Preflow

Set

Cutflow

Minimum

Clearance

Equivalent

Material

Thickness

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce

Height

Pierce Delay

Time

Plasma

gas

Shield

gas

Plasma

gas

Shield

gas

Plasma

gas

Shield

gas

mm mm Range (mm) mm/m mm Factor % Seconds

O

2

Air 22 20 74 19 2.0

25 3.6 – 7.6 1685 9.0 250 0.8

28

4.8 – 7.6

1445

9.5 200

1.0

32 1135 1.2

38* 895 3.0

44 580

Edge start

50 405

58 290

64 195

Metric

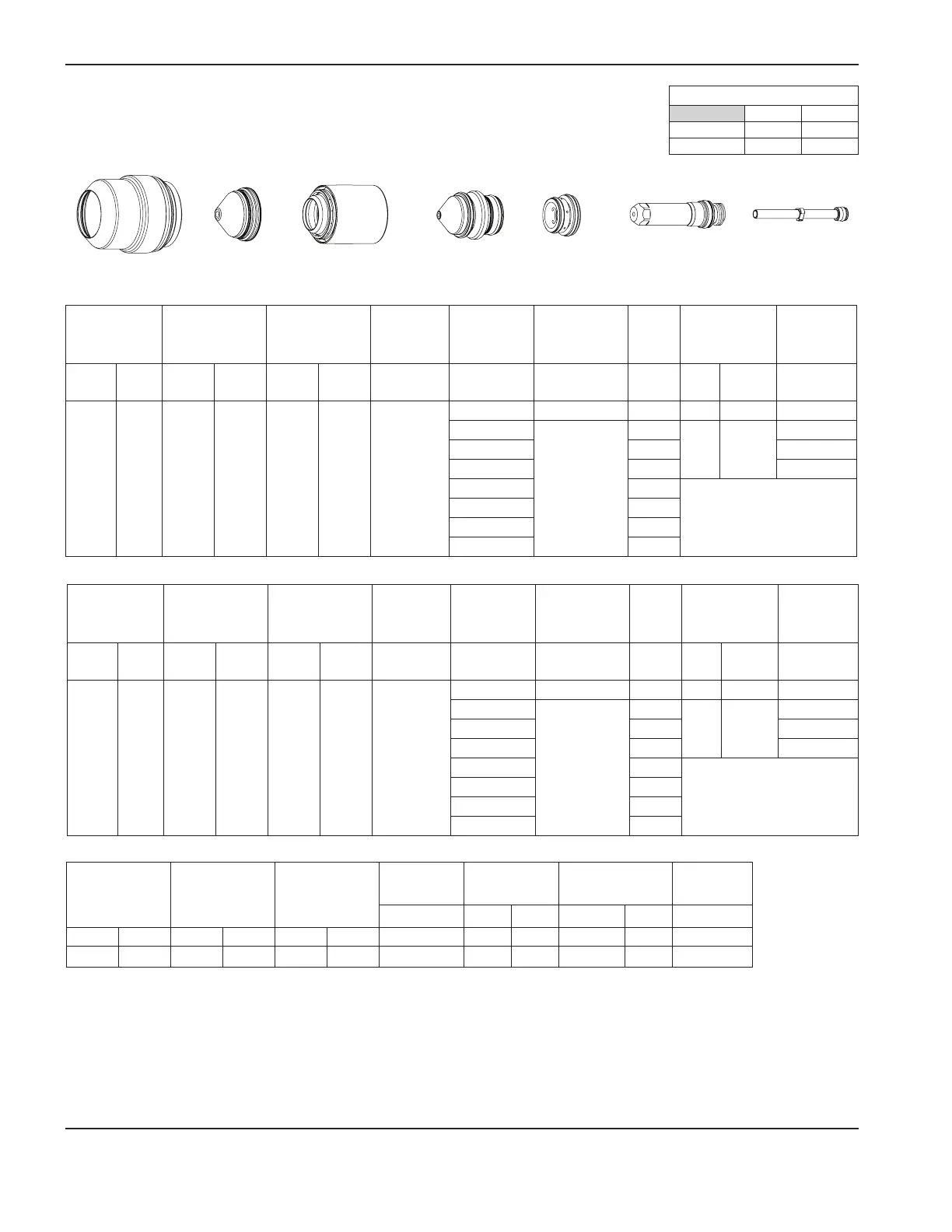

Select

Gases

Set

Preflow

Set

Cutflow

Minimum

Clearance

Equivalent

Material

Thickness

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce

Height

Pierce Delay

Time

Plasma

gas

Shield

gas

Plasma

gas

Shield

gas

Plasma

gas

Shield

gas

in in Range (in) ipm in Factor % Seconds

O

2

Air 22 20 74 19 0.08

1 0.14 – 0.30 65 0.35 250 0.8

1-1/8

0.19 – 0.30

55

0.38 200

1.0

1-1/4 45 1.2

1-1/2* 35 3.0

1-3/4 22

Edge start

2 15

2-1/4 12

2-1/2 8

English

Select

Gases

Set

Preflow

Set

Cutflow

Amperage

Torch-to-Work

Distance

Marking

Speed

Arc

Voltage

Amps mm in mm/m ipm Volts

N

2

N

2

10 10 10 10 18 2.5 0.10 6350 250 122

Ar Air 30 10 30 10 24 3.0 0.12 2540 100 62

Marking

Mild steel bevel cutting (alternate)

thick metal piercing

O

2

Plasma / Air Shield

260 A

220897220637 220899220896 220436220898 220571

Flow rates – lpm/scfh

O

2

Air

Preflow 0 / 0 85 / 180

Cutflow 47 / 99 54 / 115

The consumables on this page are designed for thick metal piercing. They are only recommended for use if you have

a problem with excessive slag on the shield, or problems with the torch misfiring, when using the standard bevel

consumables.

Using the thick metal piercing process may result in a 20% decrease in the life of the consumables.

* Suggestions for piercing 38 mm (1-1/2 in) mild steel:

1. Turn preflow on during IHS

2. Use stall force during IHS

3. Use pierce complete when piercing

Loading...

Loading...